A part-level simulation test piece design verification method based on finite element simulation analysis

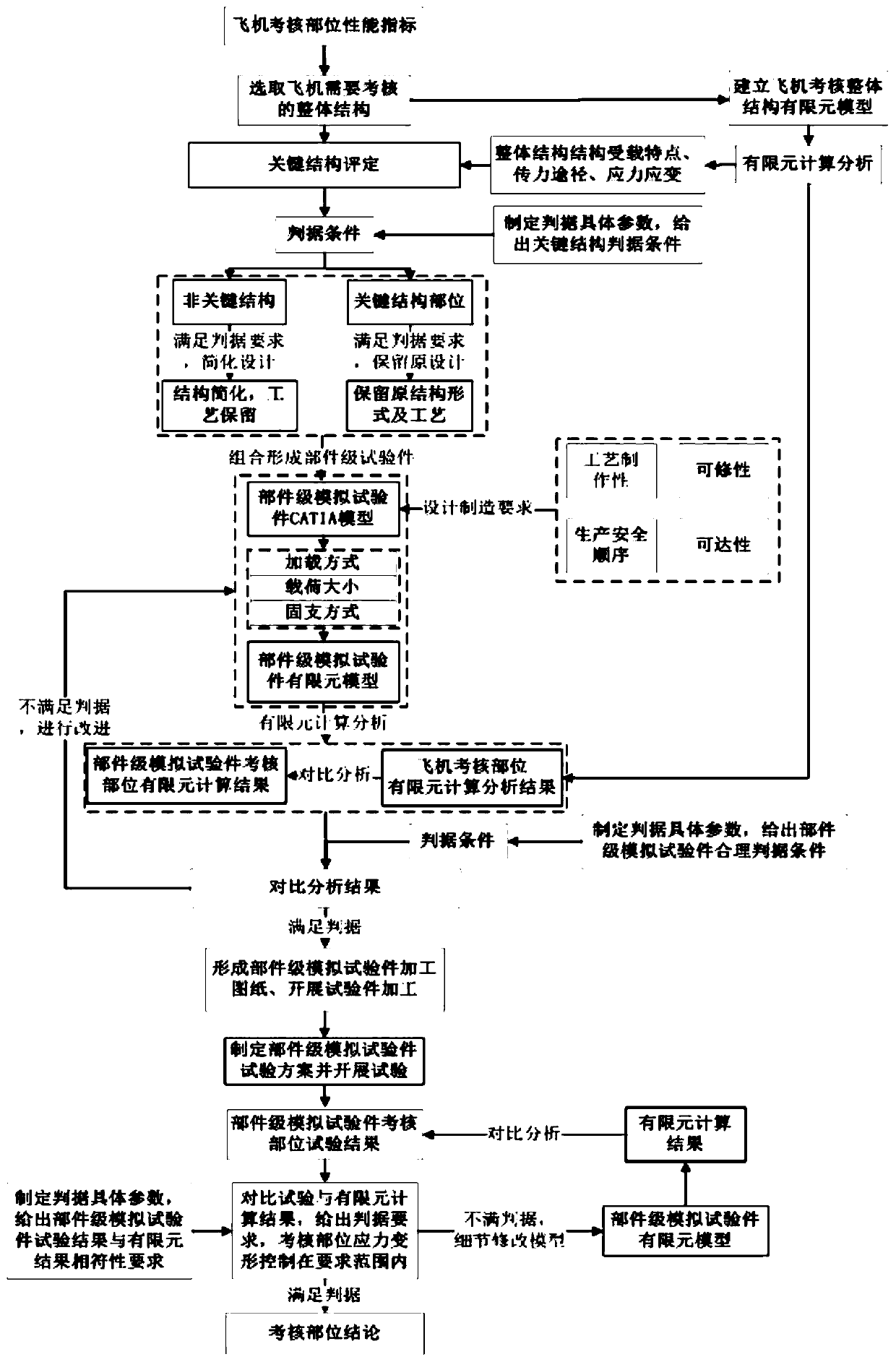

A technology of simulation test and simulation analysis, applied in verification test, component-level simulation test piece design verification, demonstration, component-level simulation test piece design field, can solve unreasonable test piece simplified design and lack of component-level simulation test piece design verification Methods, cost waste and other problems, to improve the analysis and verification capabilities of finite element software, reduce costs, and reduce test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be described in detail in combination with the summary of the invention and the drawings.

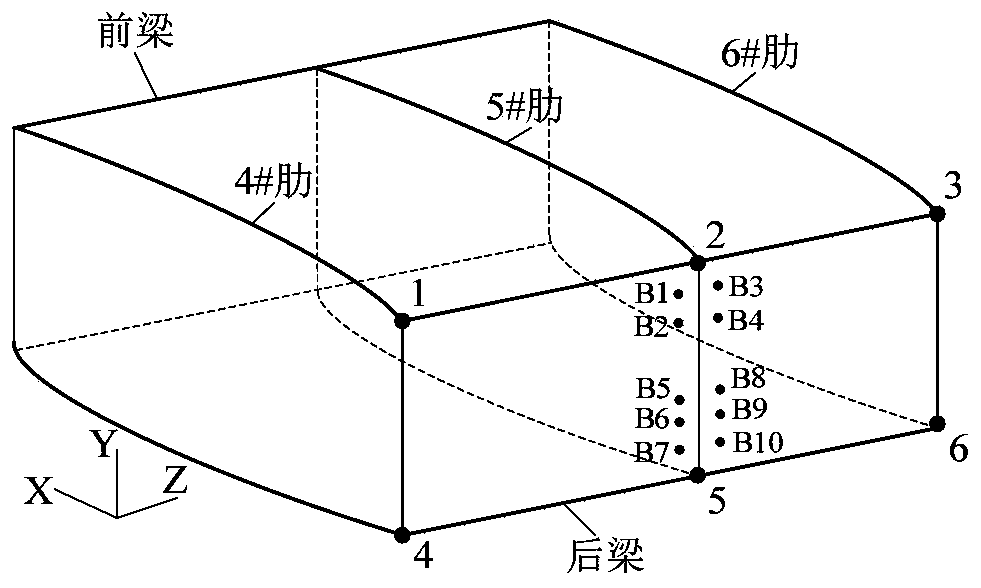

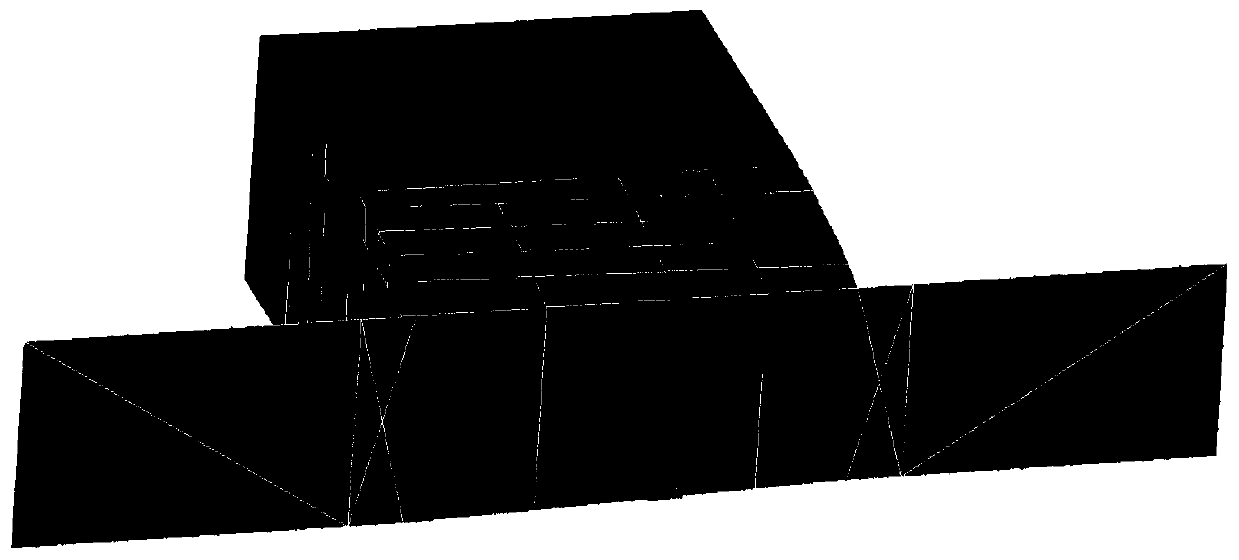

[0024] By taking the seal durability design verification of the wing fuel tank as an example, the component-level simulation test piece design verification method is described in detail. Aiming at the problem of oil leakage at the connection between the wing slide rail and the web of the outer wing box section of the aircraft, Finite element simulation analysis and verification test verify the durability of the fuel tank seal.

[0025] a) Selection of aircraft fuel tank structure and finite element calculation and analysis

[0026] 1) According to the oil leakage position of the aircraft fuel tank, a preliminary theoretical analysis of the structure and load characteristics of the aircraft fuel tank is carried out, and it is clear that the sealing durability design verification test site of the wing fuel tank is the connection pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com