Remote data monitoring unit for bucket wheel excavator

A technology of remote monitoring and data unit, applied in the direction of program control, computer control, instruments, etc., can solve the problems of remoteness, the inability to understand and monitor the working status of excavators in real time, and the inability of manufacturers to clearly understand the working status of machinery. Achieve the effect of preventing electrical failure, improving service efficiency, improving communication and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

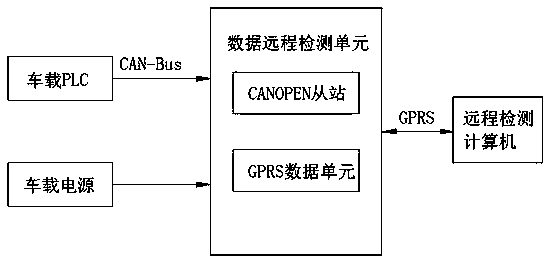

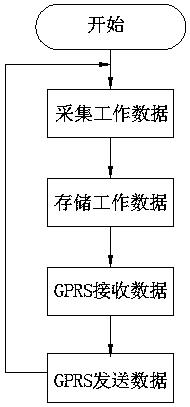

[0023] refer to Figure 1-2 , a bucket wheel excavator data remote monitoring unit, the bucket wheel excavator controller uses a programmable logic controller (PLC) that supports the CANOPEN protocol as the controller, the communication between the controller and the data monitoring unit uses the CAN bus, and the PLC is used as the network The master station transmits the status data of the bucket wheel excavator to the CANOPEN slave station of the data remote monitoring unit, the communication baud rate is 250kbps, and the power supply of the data remote monitoring adopts the vehicle.

[0024] The data remote monitoring unit is responsible for receiving and forwardi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com