Die capable of realizing high-flux component screening and forming method thereof

A high-throughput, mold-based technology, applied in the preparation of test samples, etc., can solve problems such as low efficiency, weighing error, cumbersome work steps, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

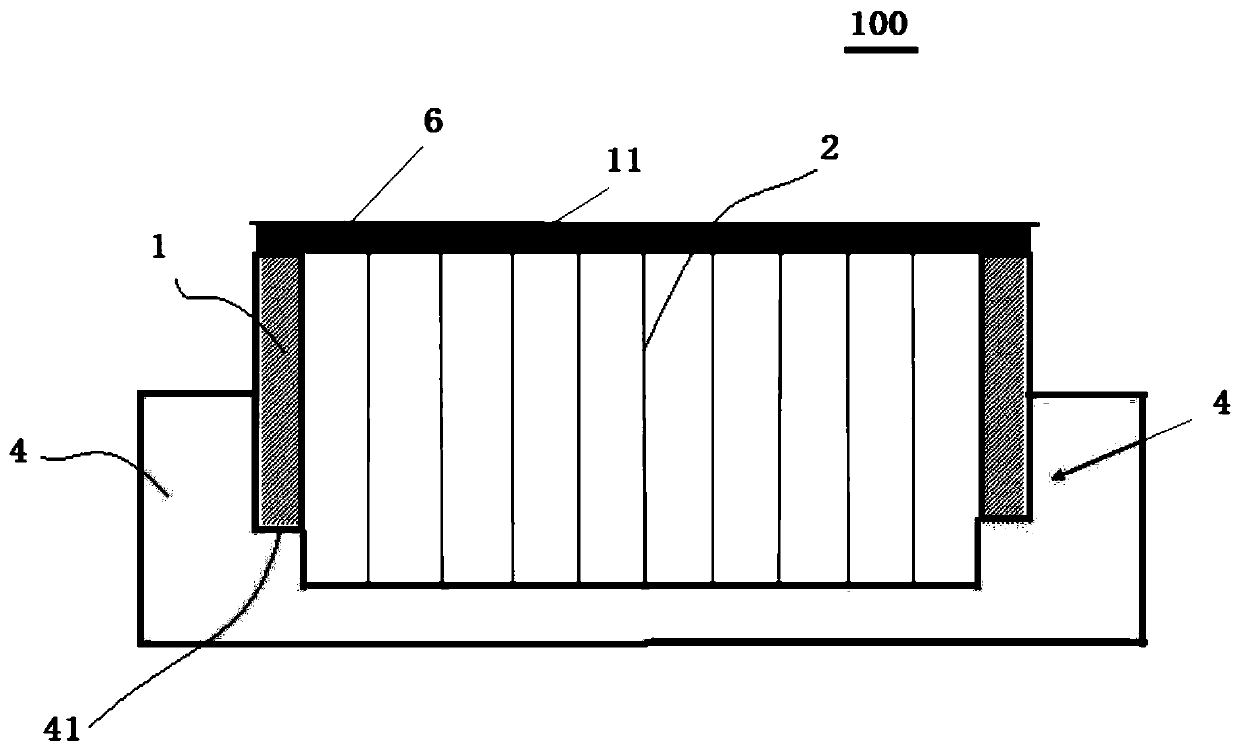

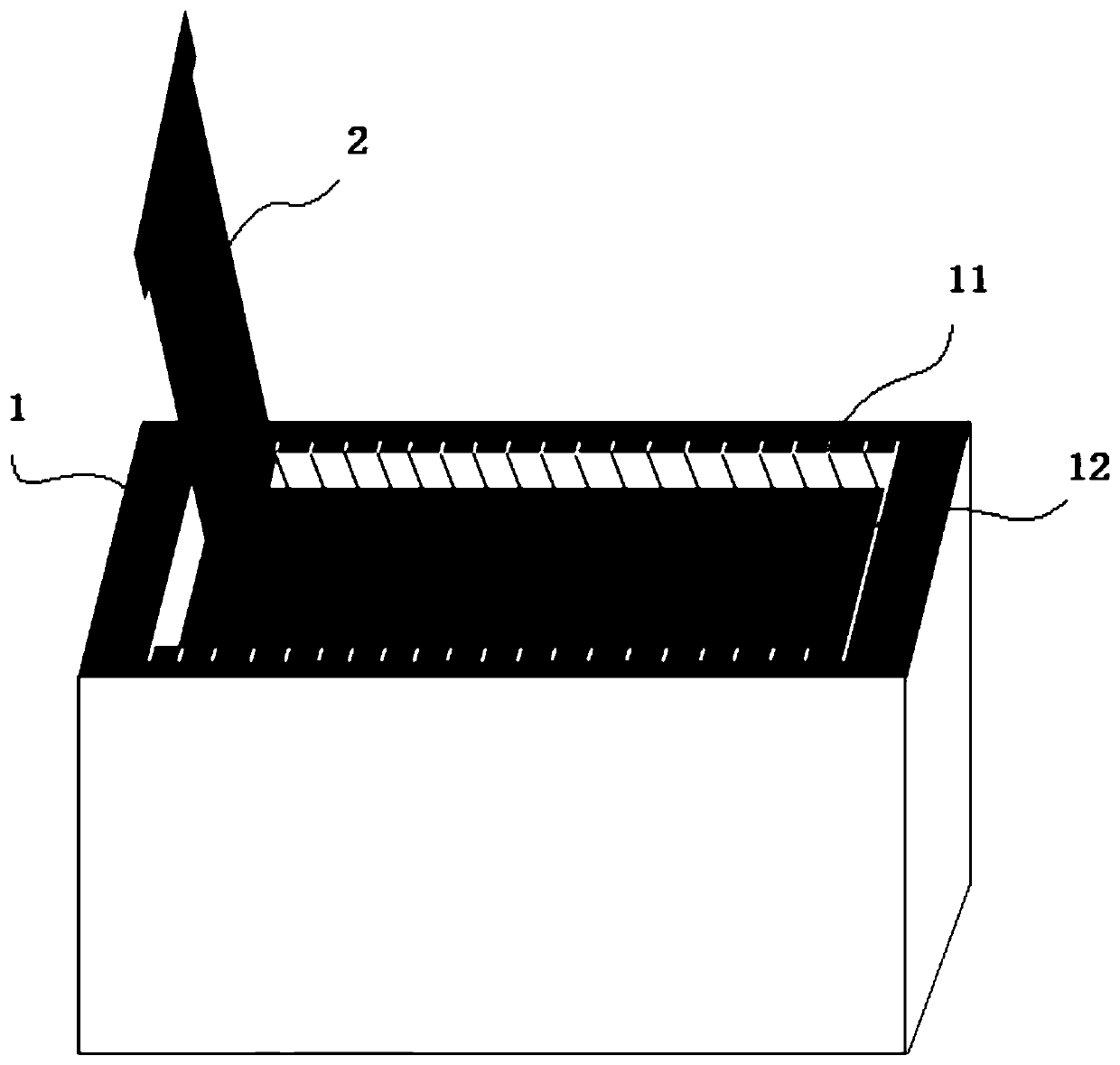

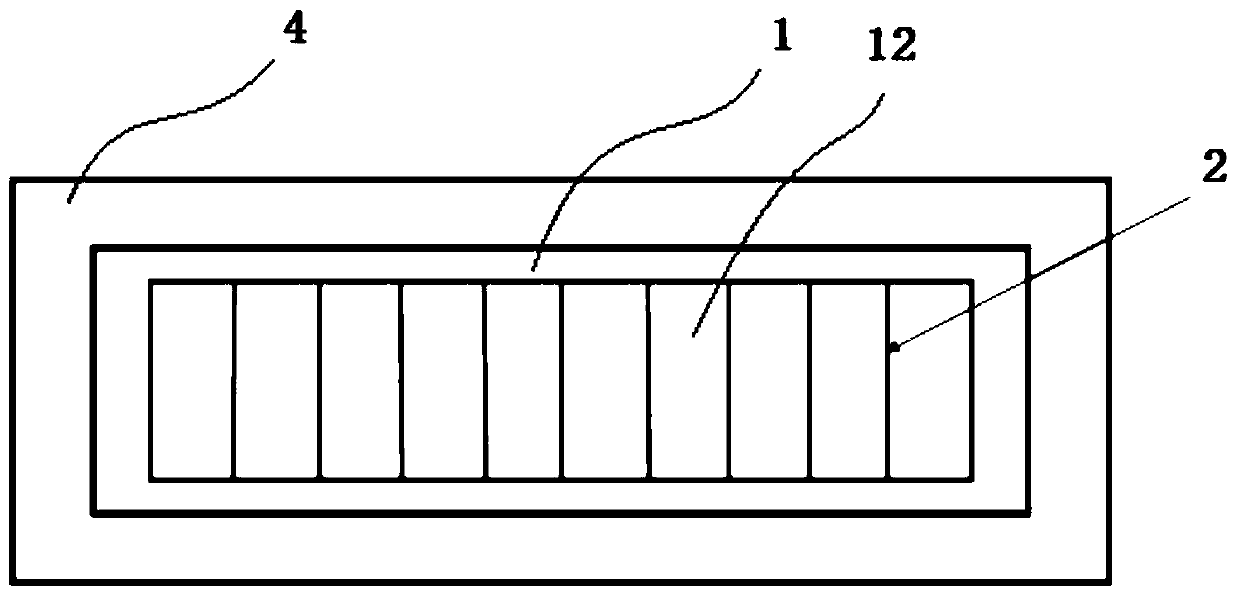

[0053] figure 1 is a schematic main cross-sectional view of a mold capable of high-throughput component screening according to an embodiment of the present application. figure 2 It is a schematic perspective view of a charging mold cavity inserted with a plurality of transverse partitions according to an embodiment of the present application. image 3 It is a schematic top view of a charging mold cavity inserted into a plurality of transverse partitions and loaded into a base according to an embodiment of the present application. Figure 7a is a schematic structural diagram of an indenter according to an embodiment of the present application. Figure 7b is a schematic structural diagram of an indenter according to another embodiment of the present application. Figure 8a It is a schematic structural view of the indenter assembled in the charging cavity according to an embodiment of the present application. Figure 8b A schematic structural view of the indenter assembled in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com