Squeeze oil film damper distributed pressure test device and test method

A technology of squeeze oil film damping and pressure testing, which is applied in the direction of fluid pressure measurement using optical methods, and can solve problems such as the inability to obtain effective experimental data of squeeze oil film damper pressure, the inability to achieve effective testing of distributed pressure, and the inability to verify theoretically. , to achieve the effects of reducing the influence of test results, convenient sensor layout, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

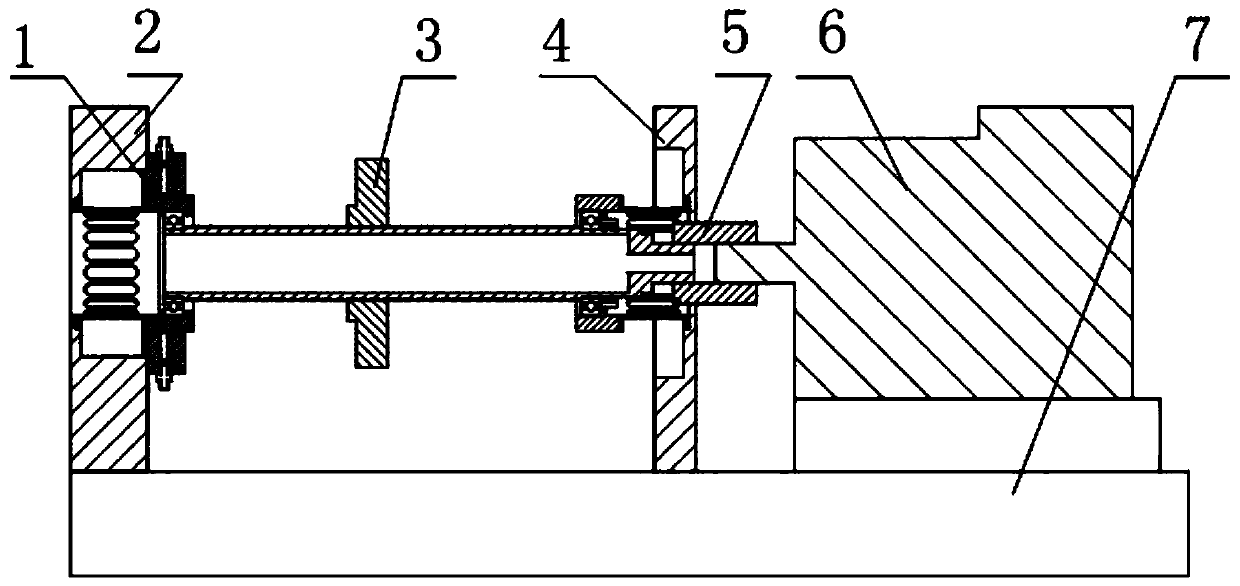

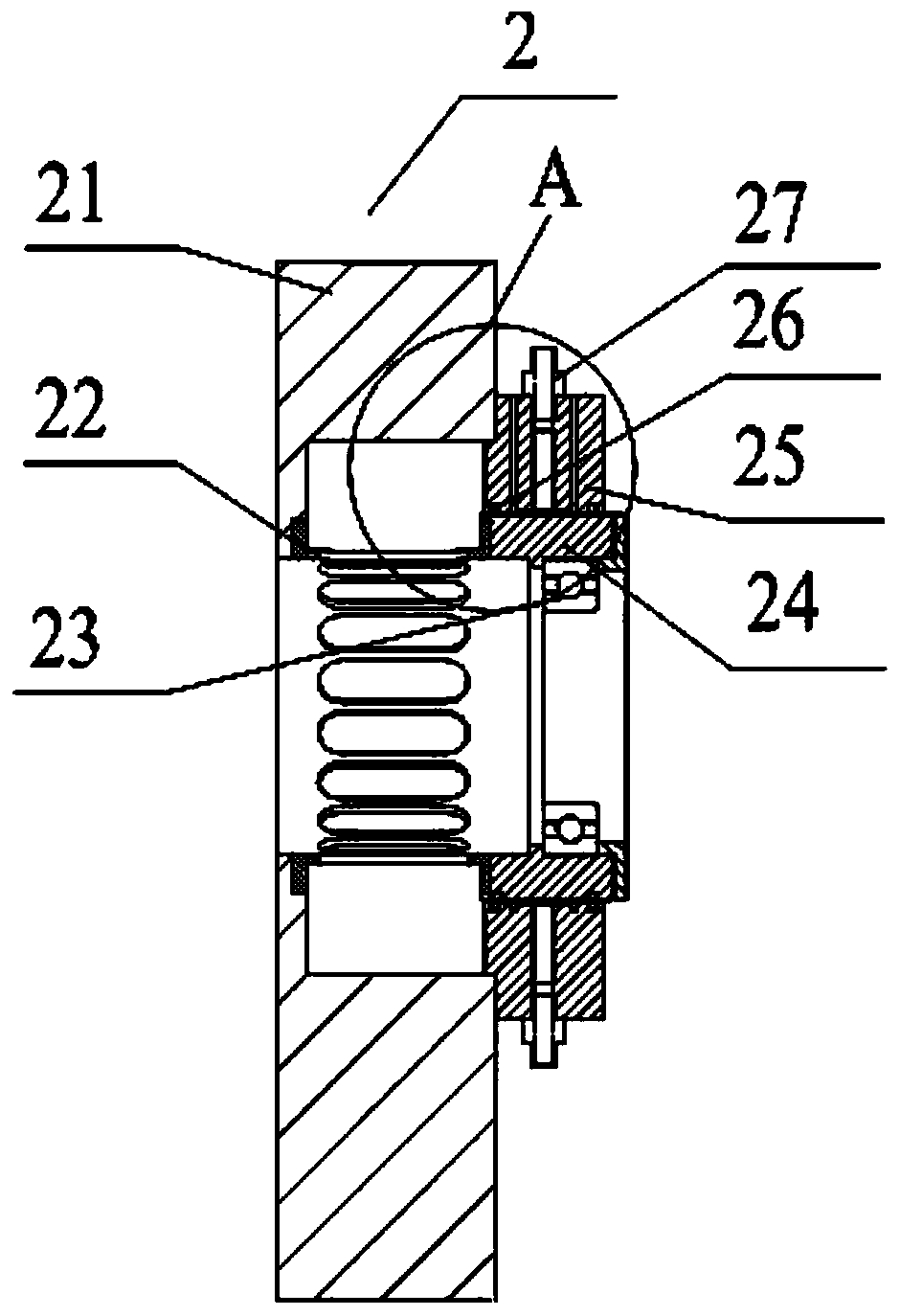

[0032] Such as figure 1As shown, the distributed pressure test device for squeeze oil film damper based on fiber grating sensing consists of a fiber grating sensing test device 1, a first support 2, a turntable shaft 3, a second support 4, a coupling 5, and a drive motor 6 , base 7, the first support 2 and the second support 4 are used to support the rotation of the rotating shaft turntable shaft 3, the driving motor 6 is located on the side of the second support 4, the motor 6 is connected with the turntable shaft 3 through the coupling 5, and drives the turntable shaft 3 rotation, the drive motor 6 is fixedly connected to the base 7 through bolts, the first support 2 and the second support 4 can have the same structure, or can be different structures, for the convenience of comparison in this embodiment, the first support 2 and the second support 4 4 is described as a different structure, the first support 2 is a fulcrum with a squeeze oil film damper structure and a fiber g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com