Composite heat insulation structure resistant to long-time ablation overload

An adiabatic structure, long-term technology, used in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as good thermal insulation performance, poor erosion resistance, and incompatibility between thermal insulation structure anti-scour performance and thermal insulation performance. , to achieve the effect of improving performance and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

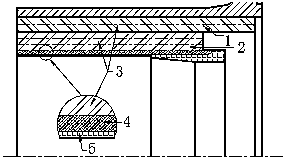

[0019] See figure 1 . The thickness ratio of the two layers of insulation materials is: GZ46-3 material thickness is 4mm, GZ46-2 material thickness is 6mm, that is, the thickness ratio is about 2:3. After molding the two layers of material insulation layers separately, use adhesive The two layers of material insulation are bonded together, and the airbag is used to pressurize and solidify the shape.

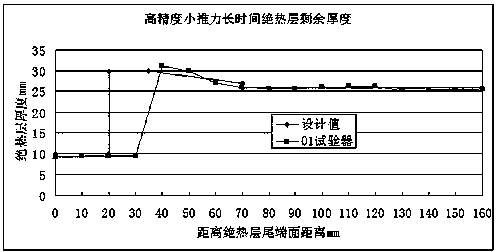

[0020] According to the thickness distribution, the tester was designed and tested on the ground for 200s. The wall of the combustion chamber of the tester was only affected by the change of ambient temperature throughout the whole process, and there was no temperature rise caused by the heat in the combustion chamber. After the test, the thickness of the remaining thermal insulation structure (without the carbonization layer, the thickness of the carbonization layer is about 4mm) was measured, see figure 2 . In the range of 60mm to 160mm from the end face of the heat insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com