Goaf rapid grouting filling bag synchronous with coal cutting and coal mining method of goaf rapid grouting filling bag

A coal mining method and bag filling technology, which are applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of poor filling support effect, slow filling speed, complicated system, etc. matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

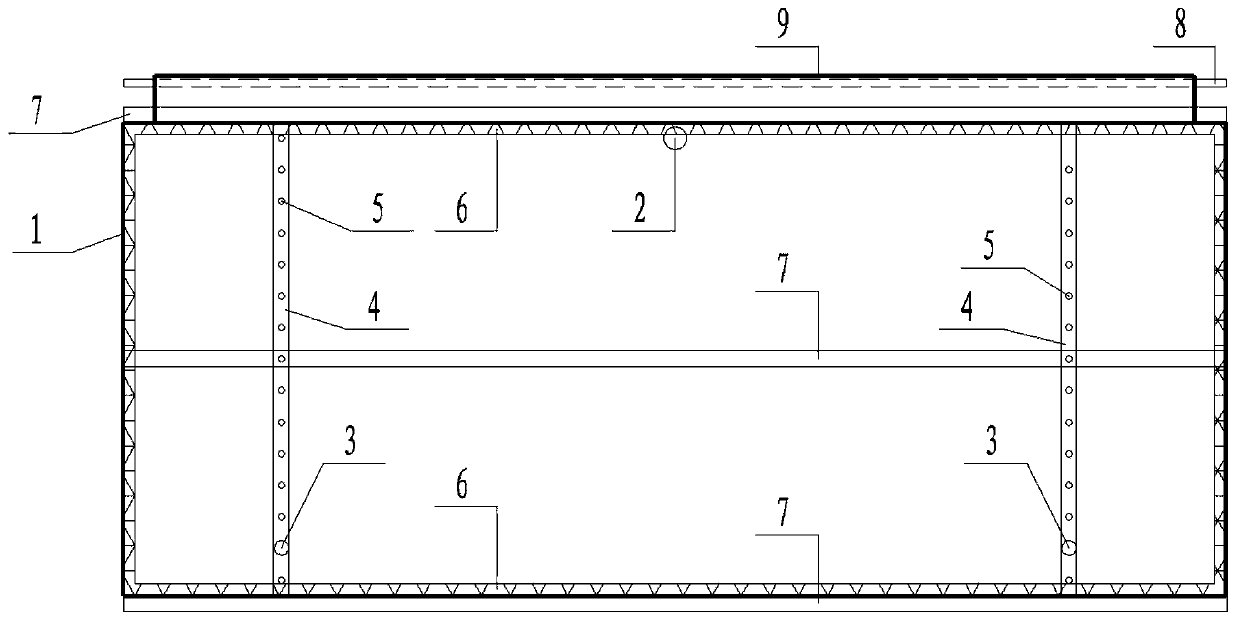

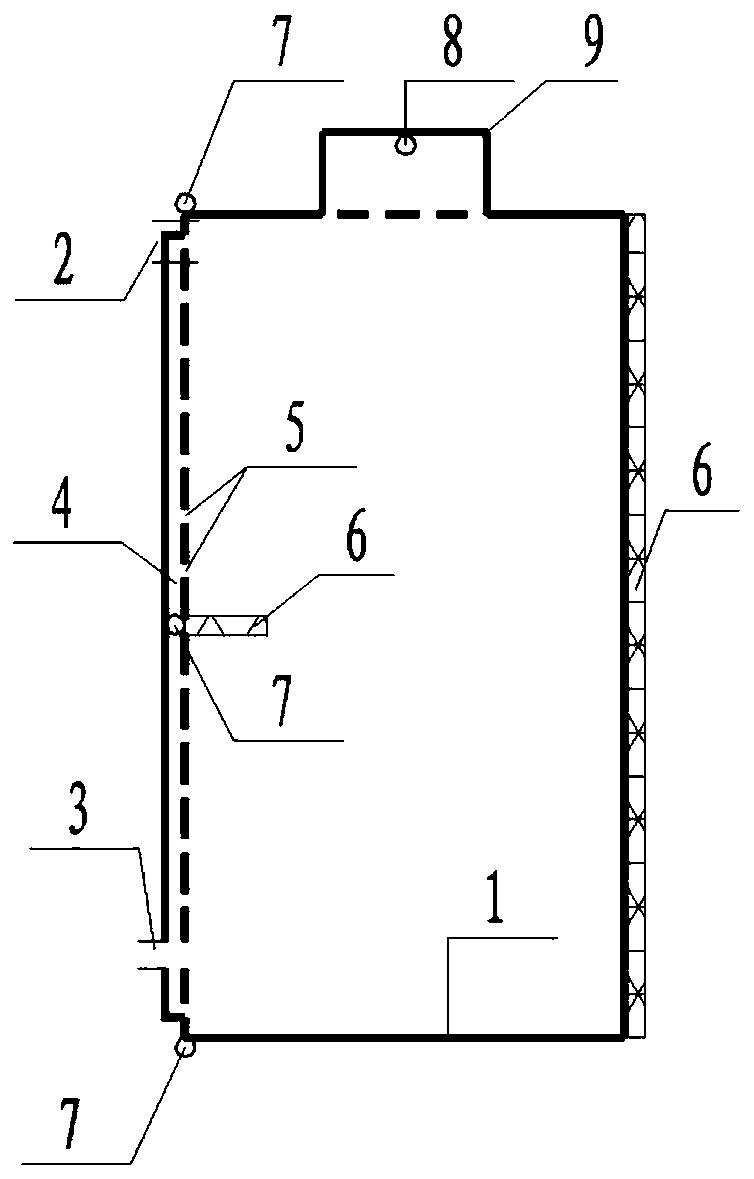

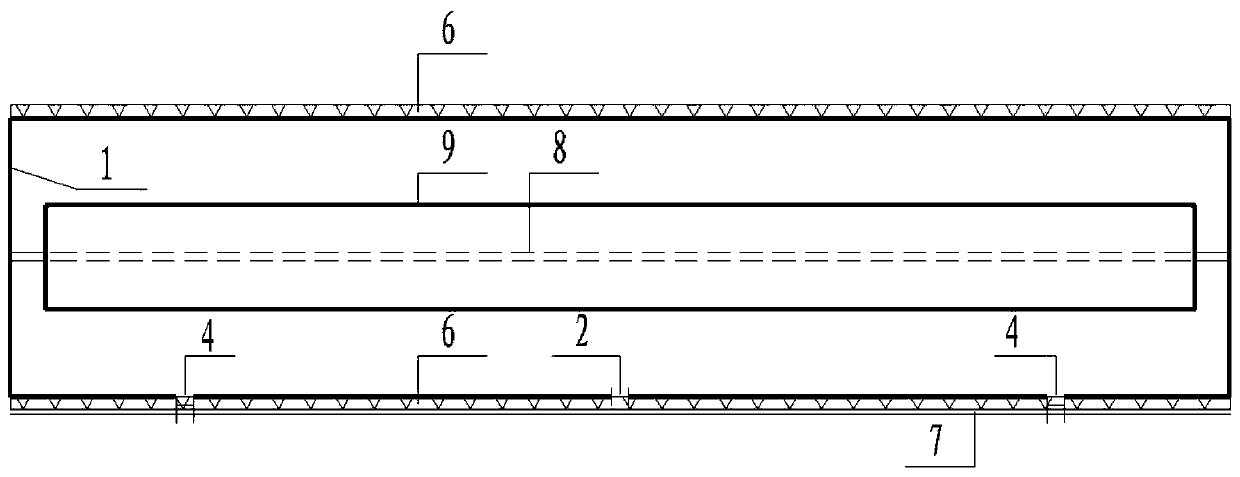

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] The present invention is a quick grouting filling bag for goaf synchronous with coal cutting (see Figure 1-Figure 3 ), including a bag body 1, the top of the bag body 1 forms a liftable roof type through a pleat structure 9, and a secondary grouting pipe 8 is arranged across the upper part of the pleat structure 9, and the outer wall of the bag body 1 is surrounded by A connecting piece 6 is provided, and the connecting piece 6 is Velcro or a hook and loop, etc. The front side of the bag body 1 is longitudinally provided with several aqueducts 4, and the surface of the bag body 1 in contact with the aqueducts 4 is provided with several Each inner drainage hole 5, the outer wall bottom of each aqueduct 4 is provided with a drainage hole 3, realizes that the sedimentation of the filler in the filling bag is discharged through the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com