Concrete vibration system for tunnel secondary lining

A concrete and tunnel technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of inability to ensure the compactness of the vault concrete, uneven strength of the tunnel lining vault concrete, uneven distribution of secondary lining vault concrete, etc. , to achieve the effect of reducing labor intensity and safety risks, reducing labor workload, and improving construction efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

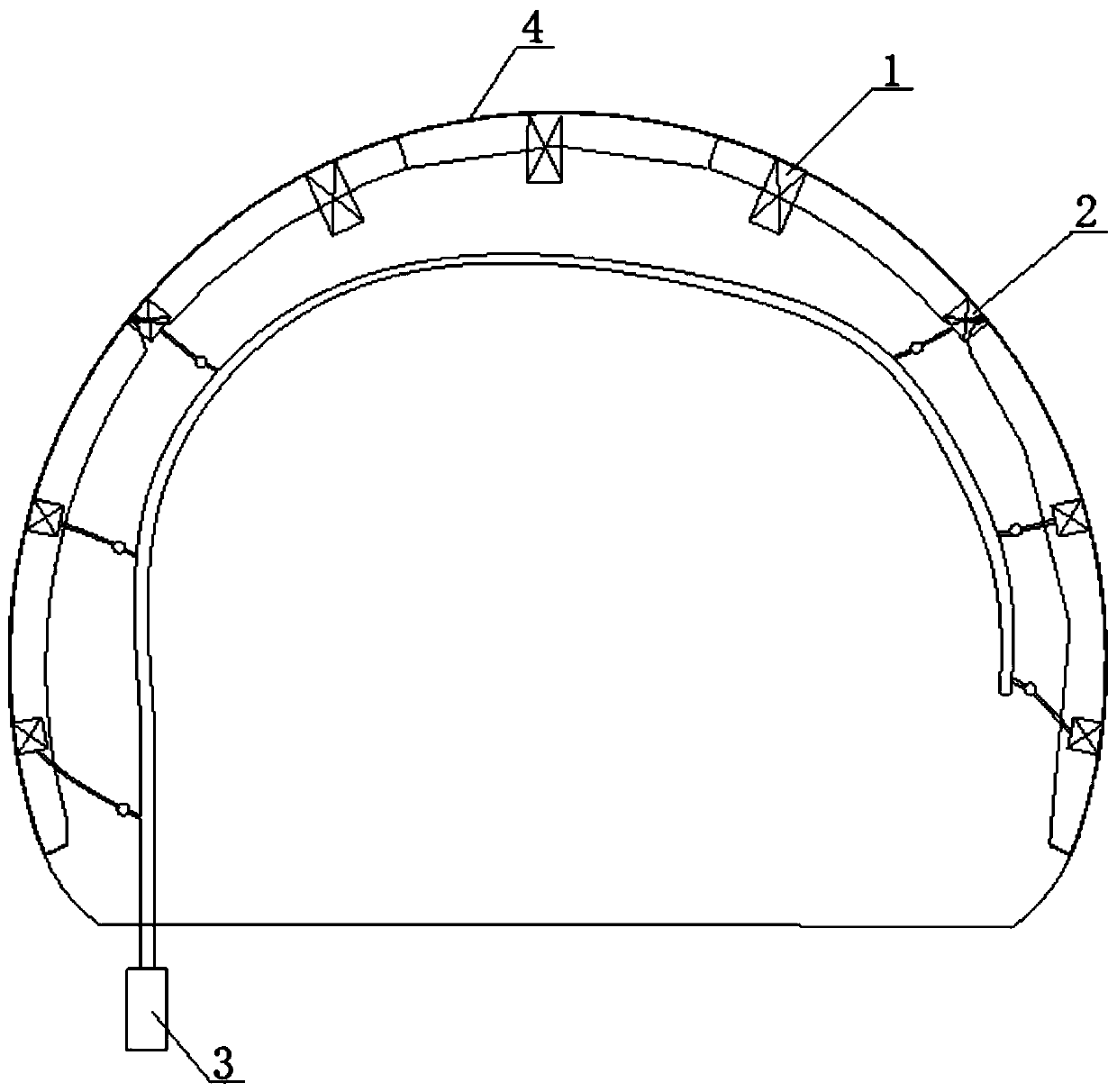

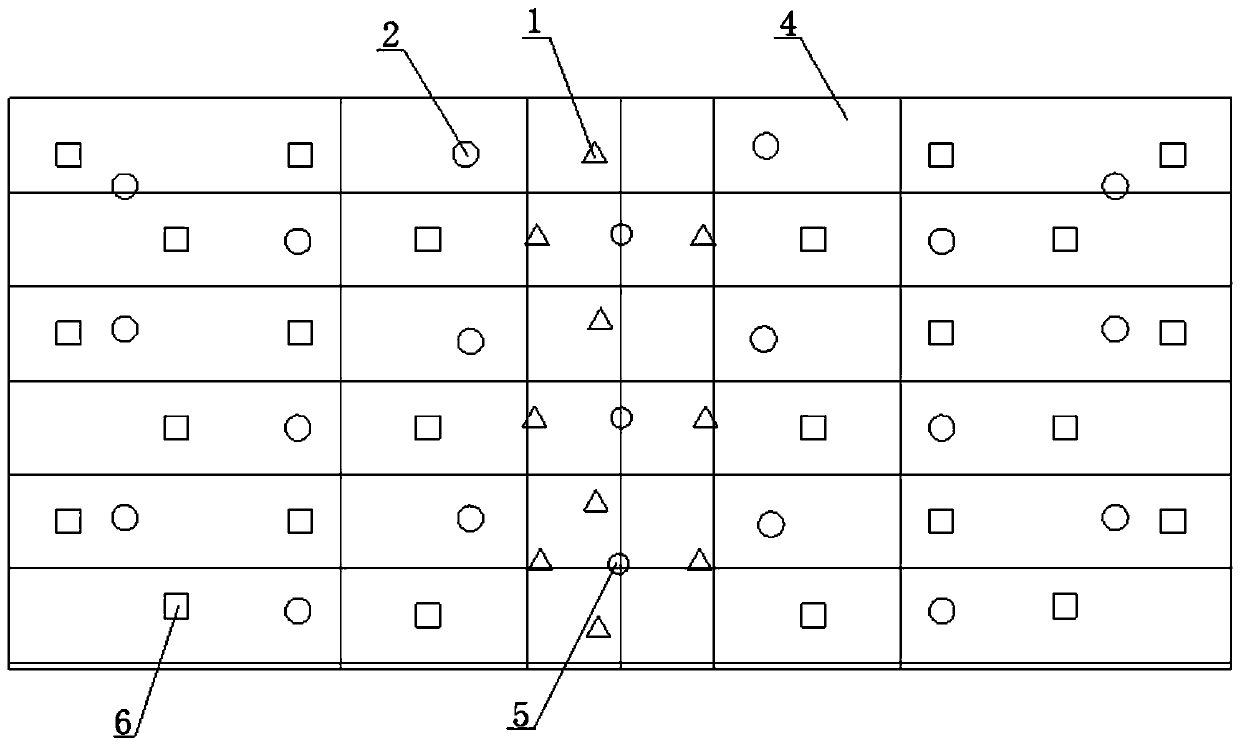

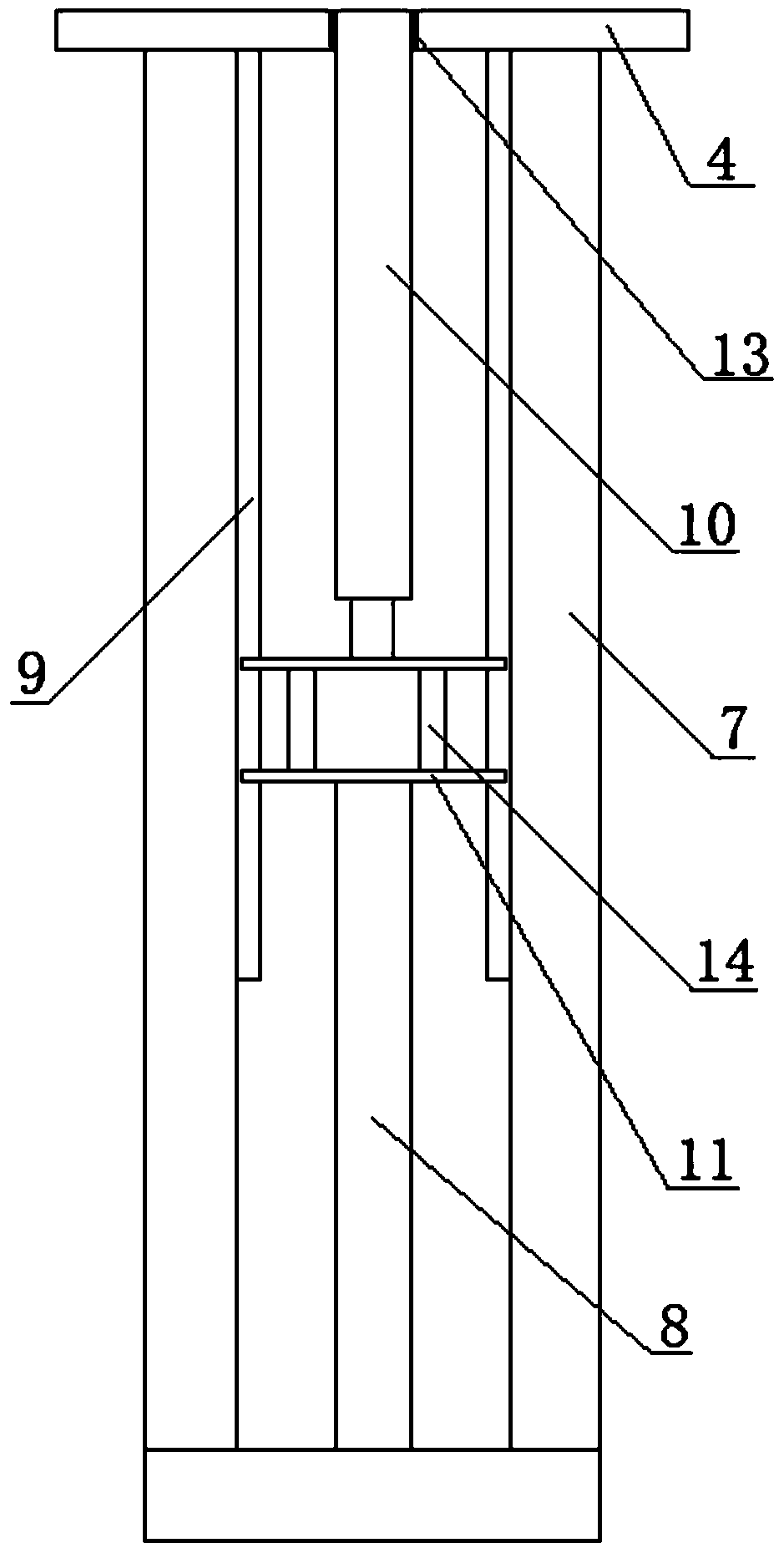

[0028] see Figure 1 to Figure 2 , a concrete vibrating system for the second lining of the tunnel, including multiple automatic plug-in vibrating devices 1, multiple high-frequency pneumatic vibrators 2, gas compressors 3 and electric control boxes, the multiple here refers to two more than one. The multiple automatic plug-in vibrating devices 1 are set on the back of the steel formwork 4 of the second lining trolley of the tunnel, and the multiple high-frequency pneumatic vibrators 2 are set on the back of the steel formwork 4 of the second lining trolley of the tunnel On the top, the back side of the steel formwork 4 of the second lining trolley is the surface of the steel formwork 10 of the second lining trolley facing the interior of the trolley; multiple automatic plug-in vibrating devices 1 are connected to the gas compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com