Method for efficiently converting furfural to gamma-valerolactone by using POMOF catalyst synthesis and one-pot method

A catalyst, valerolactone technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the complex composition method, difficult operation and low safety and other problems, to achieve the effect of strong operability, simple reaction system and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

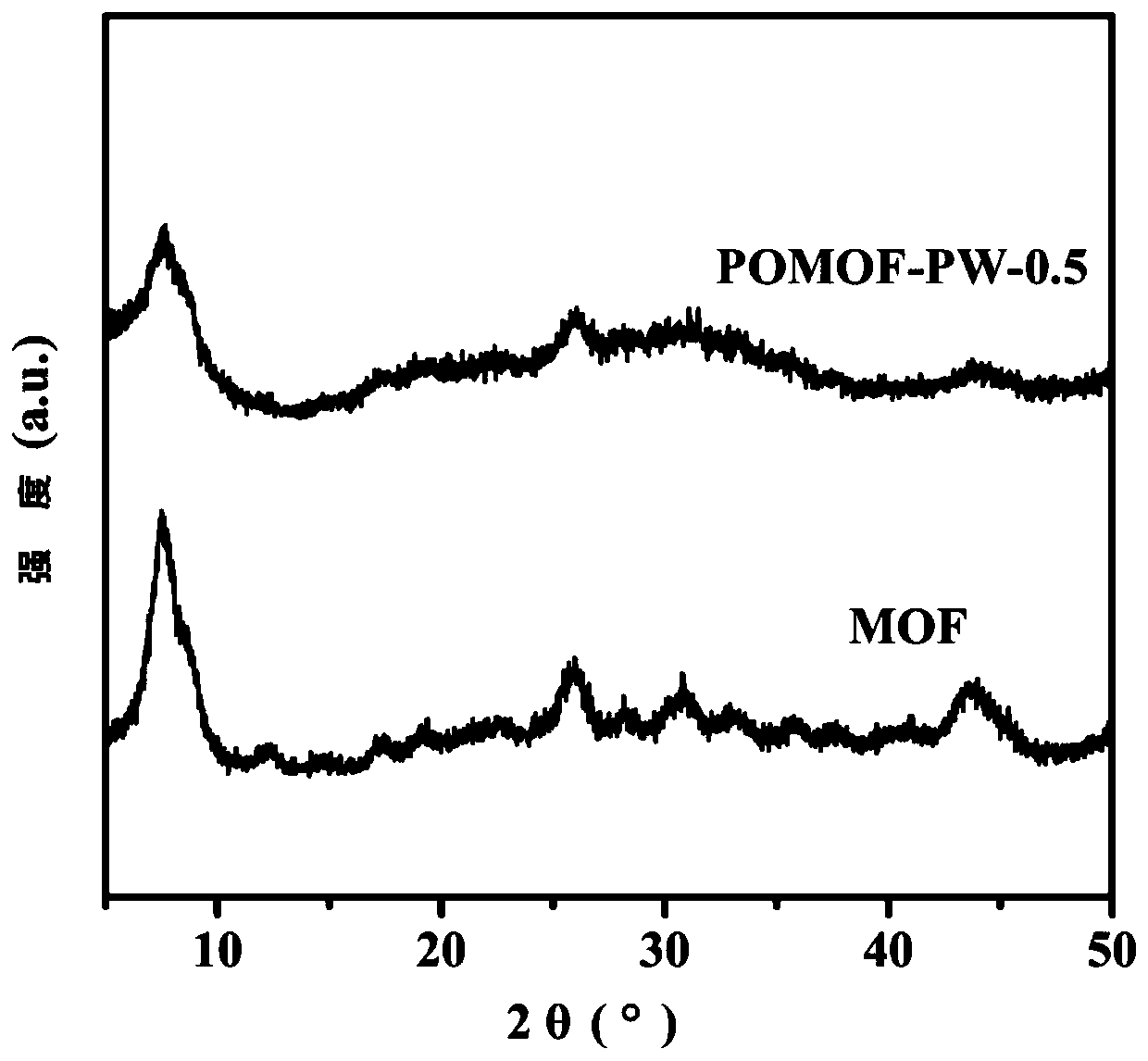

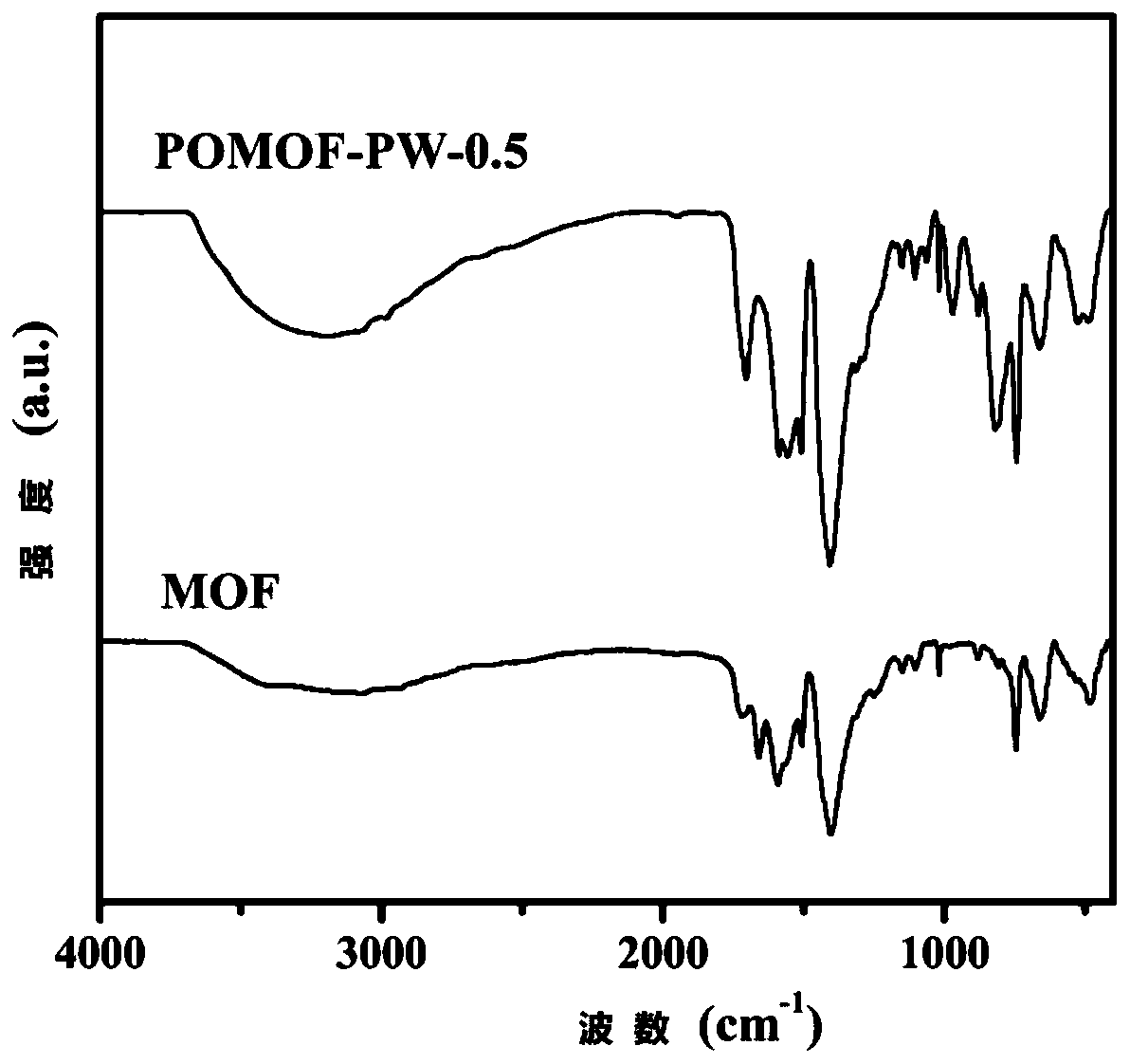

[0039] The preparation method of POMOF catalyst comprises the following steps:

[0040] Step (1), 0.9624g ZrOCl 2 ·8H 2 O and 0.6996g of terephthalic acid were dissolved in 50mL of dimethylformamide solution; then transferred to a 100mL capacity reactor, heated at 120°C for 12 hours and then cooled;

[0041] Step (2), centrifuge the product obtained in step (1) with an 8000rpm centrifuge, remove the liquid, then add dimethylformamide to wash and continue centrifuging, remove the liquid; then add water to wash and then centrifuge again, remove liquid; finally add ethanol to wash and continue to centrifuge, remove the liquid;

[0042] Step (3), cycle step (2) once, after removing the liquid for the last time, place the centrifuge tube containing the solid in an oven at 100°C for 12 hours to obtain UiO-66;

[0043] Step (4), get 1g UiO-66 and 0.1-1g H 3 [P(W 3 o 10 ) 4](PW) was dispersed in 100mL of water, put into a reflux device containing a 250mL round bottom flask, ref...

Embodiment 1

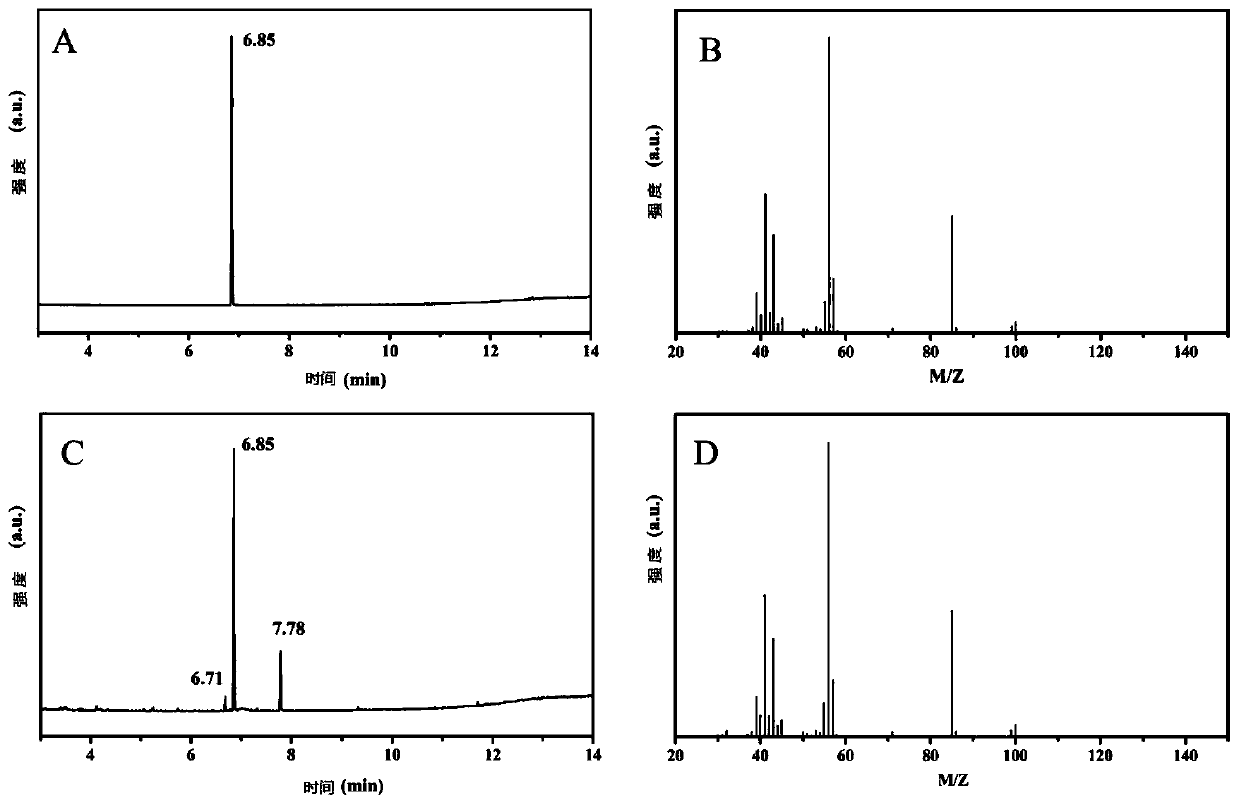

[0050] Put 0.67mmol of furfural, 0.1g of POMOF-PW-0.5, and 20ml of isopropanol into a 35mL autoclave. After sealing the autoclave, stir and react at 160°C for 23h. After the autoclave is cooled, it is ready to be tested.

[0051] The preparation method of the POMOF catalyst is as follows: dissolve 0.9624g ZrOCl2 8H2O and 0.6996g terephthalic acid in 50mL dimethylformamide (DMF); then move it into a 100mL capacity reactor, heat it in water at 120°C for 12h and then cool it down . Then centrifuge with 8000rpm centrifuge to remove the liquid, then add dimethylformamide to wash and continue to centrifuge to remove the liquid; then add water to wash and then centrifuge again to remove the liquid; finally add ethanol to wash and continue to centrifuge to remove the liquid ; The aforementioned steps of washing and centrifugation were cycled once, and after the liquid was removed for the last time, the centrifuge tube containing the solid was dried in an oven at 100°C for 12 hours, an...

Embodiment 2

[0058] Put 0.67mmol of furfural, 0.1g of POMOF-PW-0.1, and 20ml of isopropanol into a 35mL autoclave. After sealing the autoclave, stir and react at 160°C for 23h. After the autoclave is cooled, it is ready to be tested.

[0059] The preparation method of the POMOF catalyst is as follows: dissolve 0.9624g ZrOCl2 8H2O and 0.6996g terephthalic acid in 50mL dimethylformamide (DMF); then move it into a 100mL capacity reactor, heat it in water at 120°C for 12h and then cool it down . Then centrifuge with 8000rpm centrifuge to remove the liquid, then add dimethylformamide to wash and continue to centrifuge to remove the liquid; then add water to wash and then centrifuge again to remove the liquid; finally add ethanol to wash and continue to centrifuge to remove the liquid ; The aforementioned steps of washing and centrifugation were cycled once, and after the liquid was removed for the last time, the centrifuge tube containing the solid was dried in an oven at 100°C for 12 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com