Inner sliding block mechanism, connector demolding device and demolding method

An inner slider and connector technology, applied in the coating and other directions, can solve the problems of difficult demoulding, easy damage to the bosses of hardware, affecting the welding effect of hardware and wires, etc., so as to improve the service life and increase the sliding Matching surfaces, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

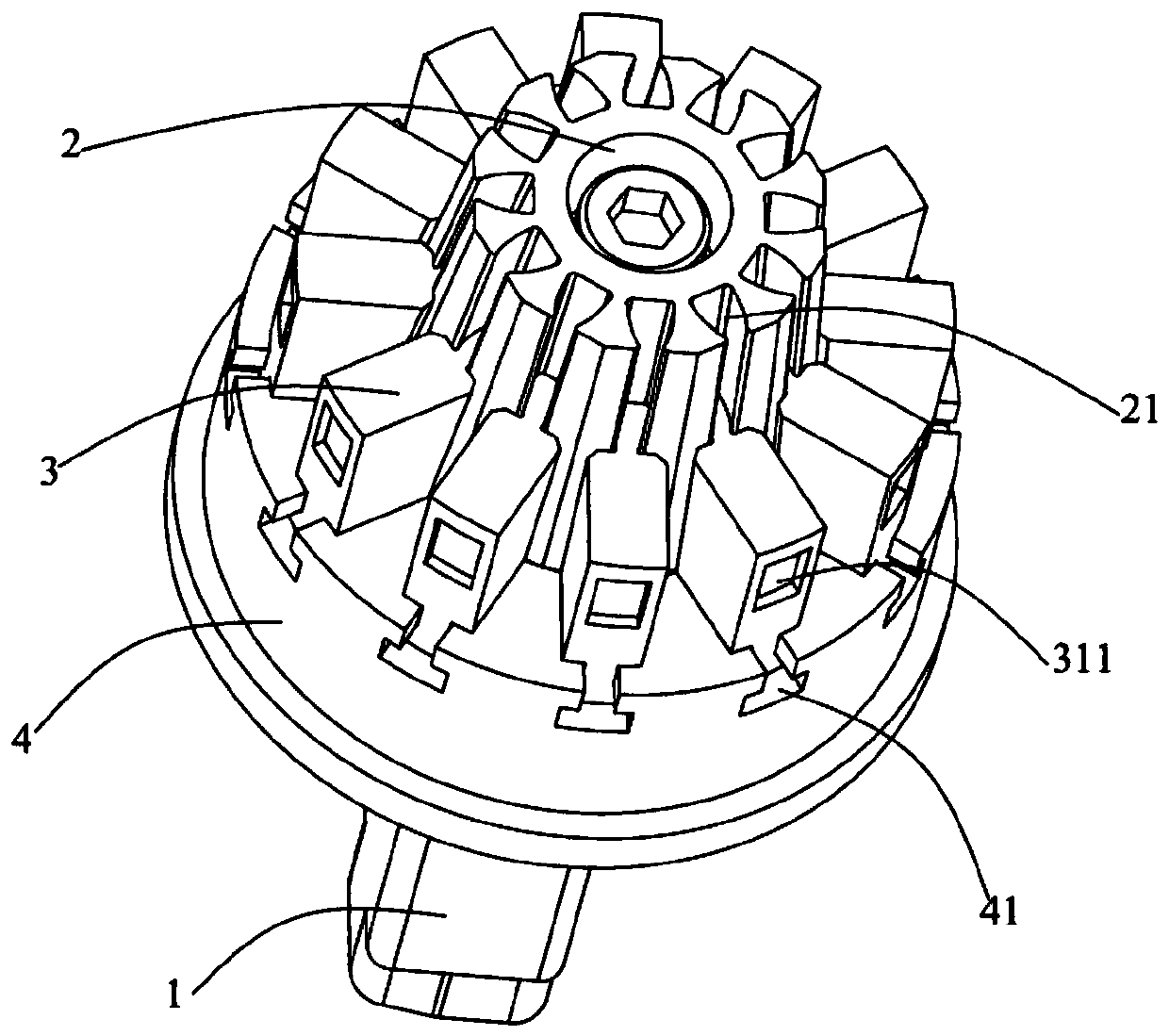

[0048] Such as Figure 1 to Figure 5 A specific implementation of the shown inner slider mechanism includes:

[0049] Slider seat insert 1, one end is fixed with slider seat 2, and the circumferential direction of described slider seat 2 is provided with a plurality of slide grooves 21 along the vertical direction, and the radial cross-sectional area of described slider seat 2 is from the first end to The second end tapers off.

[0050] A plurality of sliders 3 are slidably connected to a plurality of sliding slots 21 one by one, and grooves 311 corresponding to the parts to be disengaged are provided on the side facing away from the slider seat 2 .

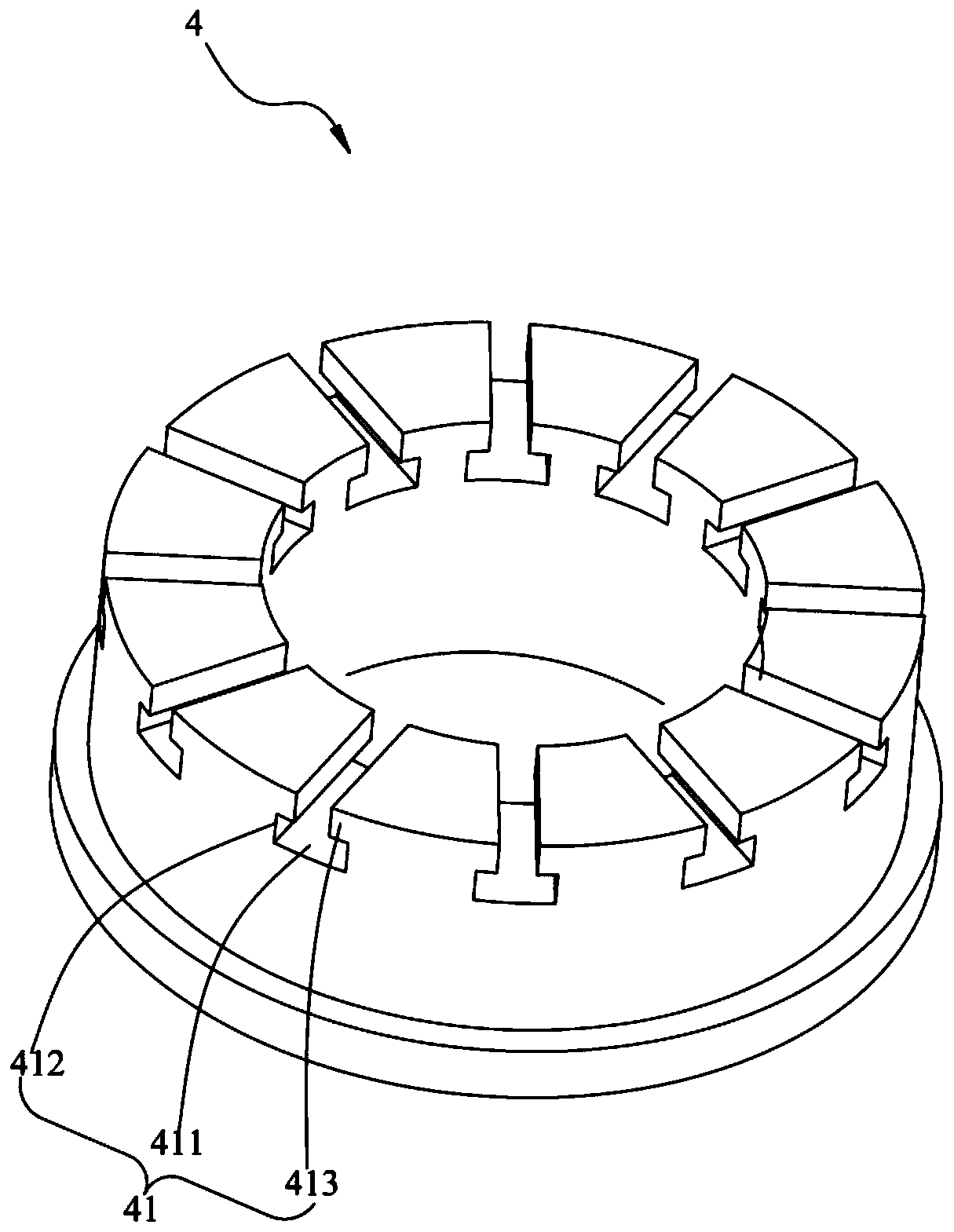

[0051] The slider guide block 4 is sleeved on the outer periphery of the slider seat insert 1, and has a limit groove 41 that is fixedly connected with the plurality of sliders 3 in the axial direction and slidably connected in the radial direction. The block guide block 4 reciprocates along the axial direction of the slider ...

Embodiment 2

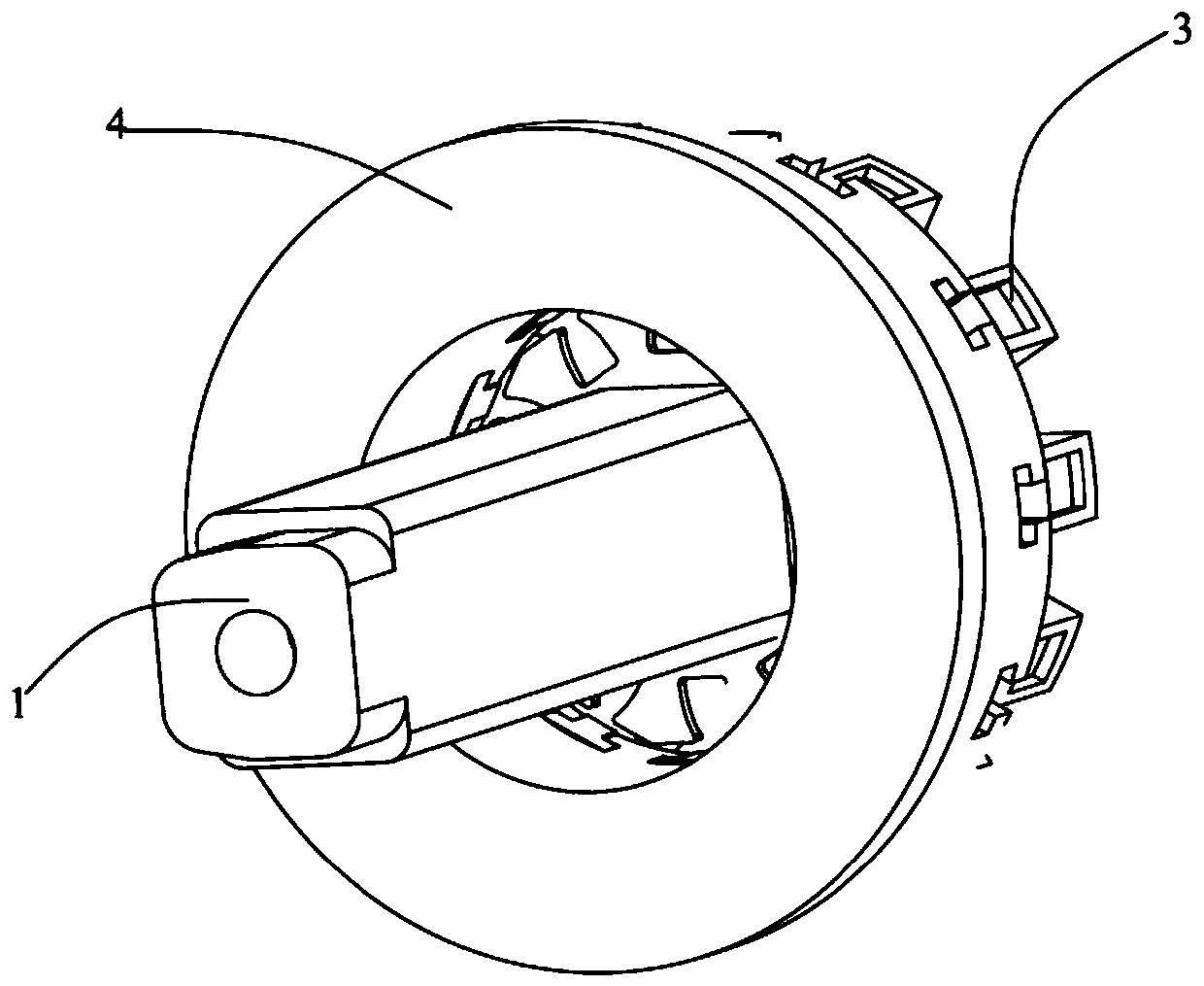

[0064] Such as Figure 6 A specific embodiment of the shown connector stripping device includes: a first plate 5, a second plate 6 and a support plate 7 arranged in parallel in the vertical direction, and the second plate 6 is provided with a first An accommodating cavity 61, a second accommodating cavity 51 is provided at a corresponding position of the first plate 5, and the inner slider mechanism described in Embodiment 1 is installed in the first accommodating cavity 61 and the second accommodating cavity 51, the The slider seat insert 1 is partly located in the first accommodation cavity 61 , passes through the first accommodation cavity 61 and is fixed on the support plate 7 , the slider guide block 4 abuts against the first The bottom wall of the receiving chamber 61 and the hardware are located in the first receiving chamber 61 and the second receiving chamber 51 .

[0065] The elastic mechanism is arranged between the second plate 6 and the supporting plate 7 , and i...

Embodiment 3

[0076] This embodiment provides a specific implementation of the connector stripping method, using the connector stripping device described in Example 2 to perform stripping, including the following steps:

[0077] After the hardware is injection-molded into a connector, the power mechanism releases the external force applied to the fixing mechanism 8, and the elastic mechanism is released to drive the second plate 6, the first plate 5 and the fixing mechanism 8 to move upwards. The slider seat insert 1 is fixed on the support plate 7, and the second plate 6 drives the slider guide block 4 and the plurality of sliders 3 to move upward, so that the groove 311 on the slider 3 separate from the hardware.

[0078] Disassemble the buckle base 9 from the first board 5 and the second board 6, separate the first board 5 and the second board 6 to take out the connector.

[0079] In the above-mentioned connector stripping method, after the hardware is injection-molded into a connector,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com