Proximal tibia osteotomy device

A technique for tibia and osteotomy, which is used in bone drill guidance, medical science, surgery, etc., and can solve problems such as the effect of joint replacement surgery, affecting the quality of life of patients, and poor accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the embodiments of the present invention are not limited thereto, and the scope of protection of the present invention also relates to those skilled in the art who can achieve according to the concept of the present invention. Think of the equivalent technical means.

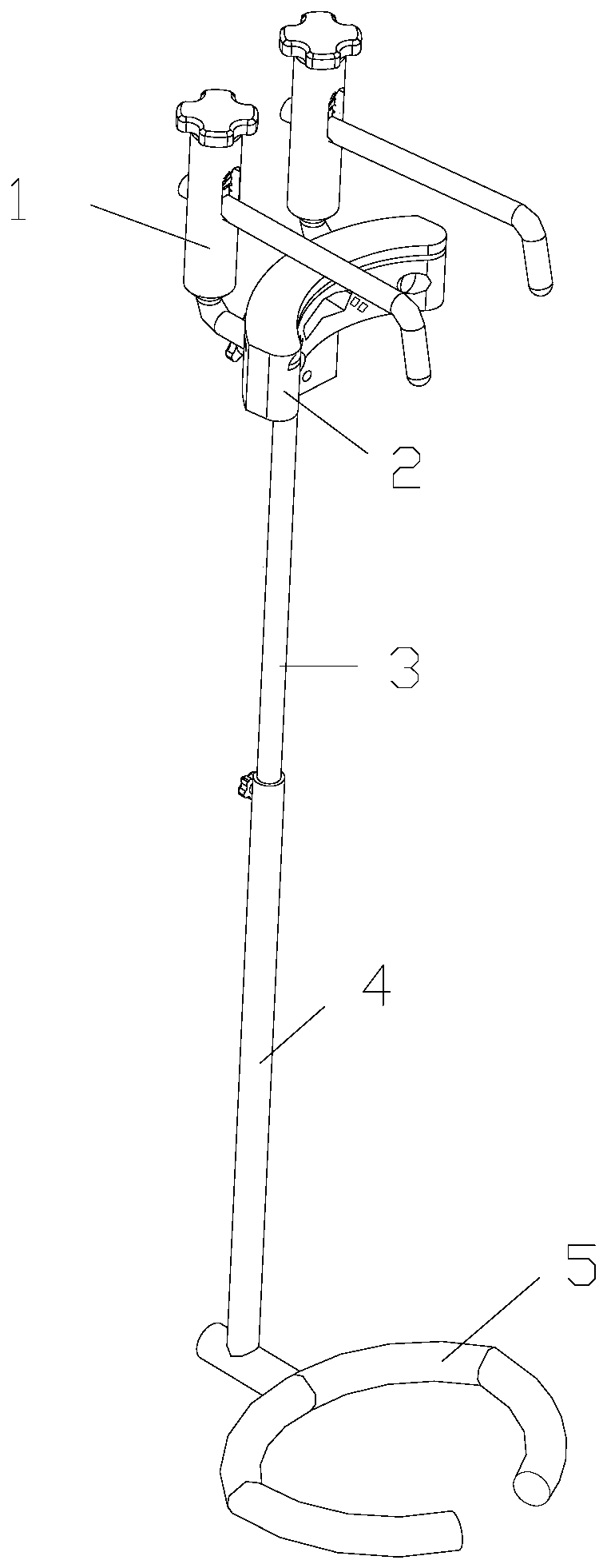

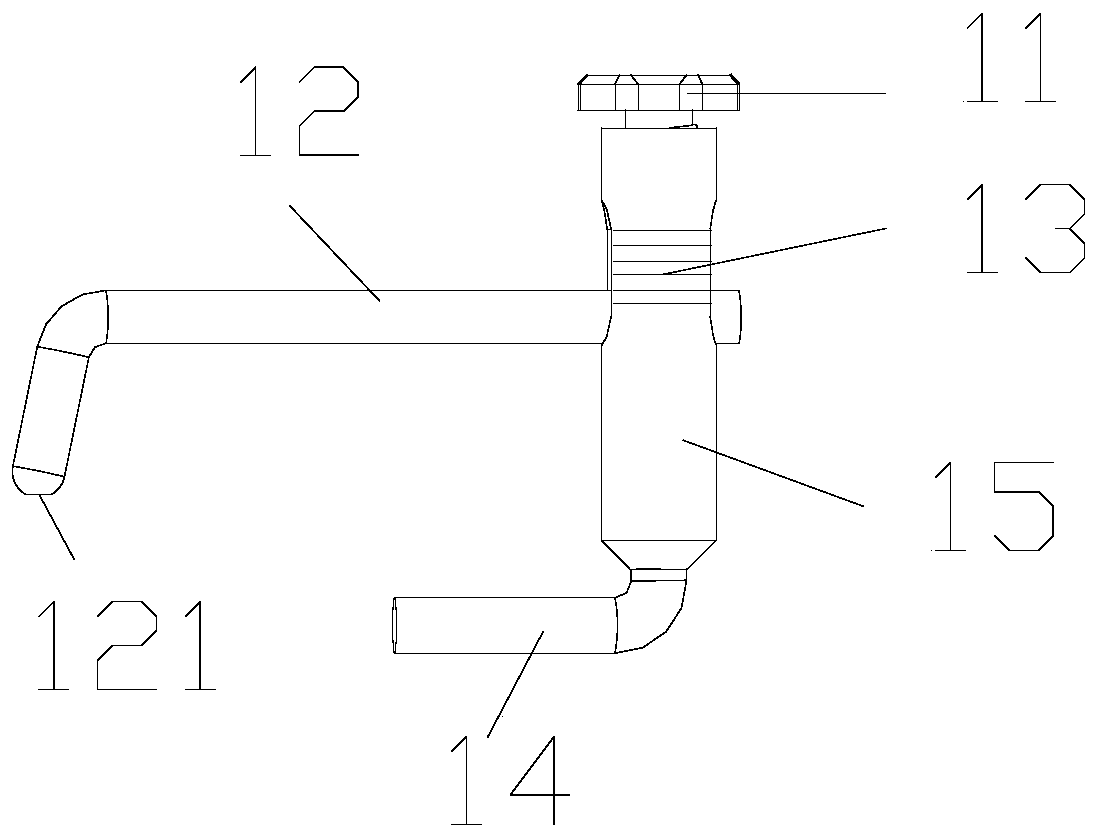

[0022] Such as Figures 1 to 4 As shown, a proximal tibial osteotomy device includes a connecting rod 3 with a pointer installed on the connecting rod 4 of the condyle holder, a tibial osteotomy guide 2 installed on the connecting rod 3 with a pointer, and a tibial osteotomy guide installed on the connecting rod 4 Two osteotomy thickness limiters 1 on 2,

[0023] The tibial osteotomy guide plate 2 includes a tibial fixation plate 26 matching the radian of the tibia and a connecting plate 25 fixed on the tibial fixing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com