Three-phase three-dimensional stacked iron core structure

A stacked iron core, three-dimensional technology, applied in the field of three-phase three-dimensional stacked iron core structure, can solve the problems of high no-load loss process coefficient, low filling coefficient, long manufacturing period, etc., achieve simple performance control measures, reduce material consumption, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

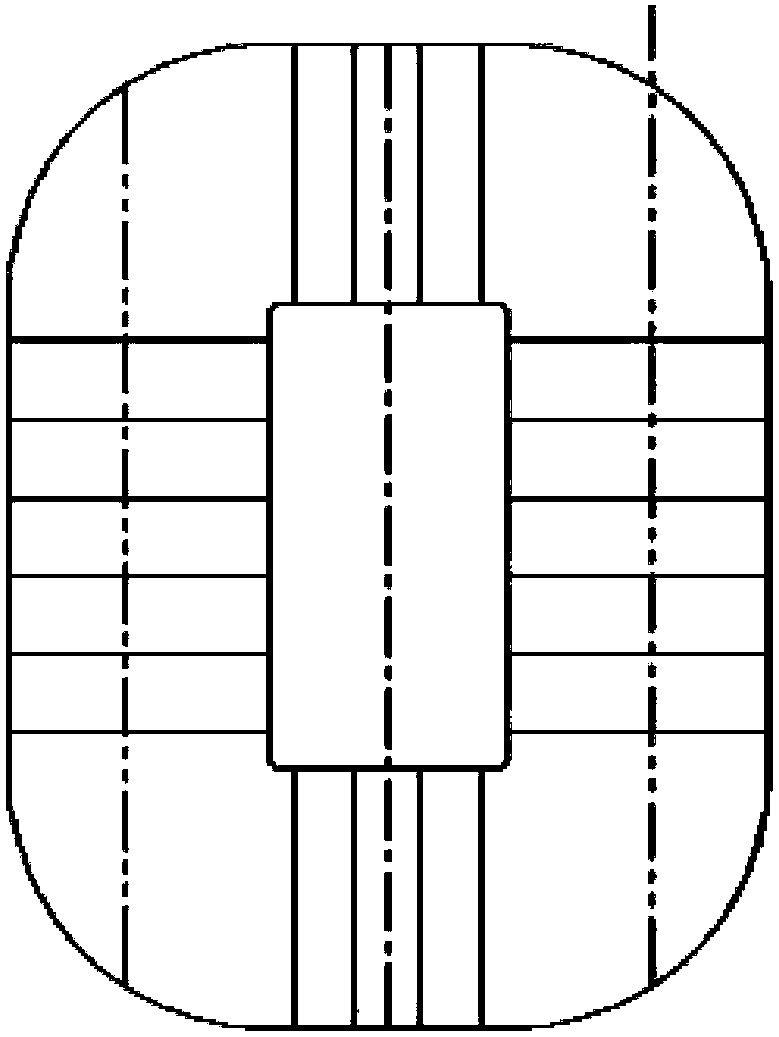

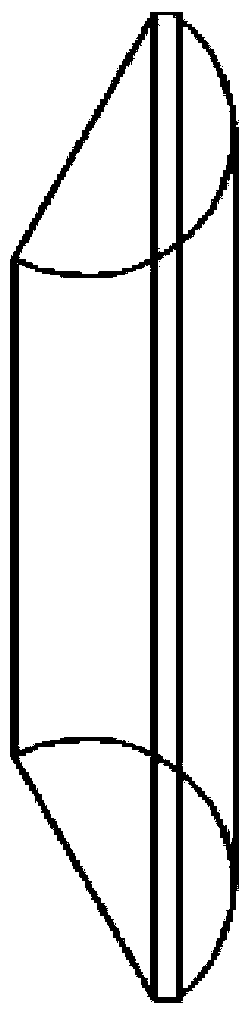

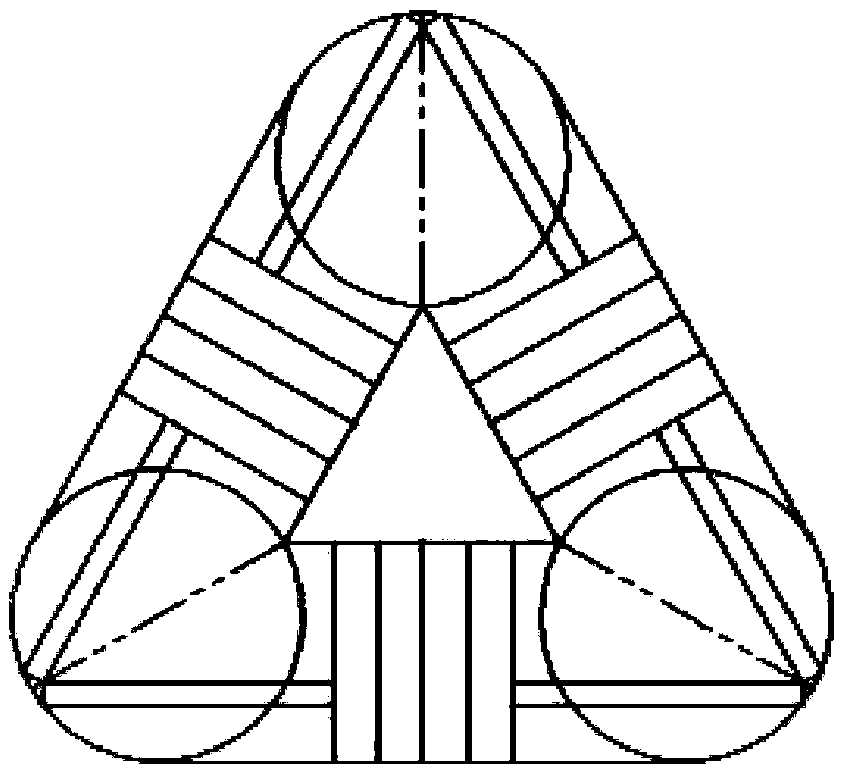

[0034] Such as Figures 4A-4C As shown, the present invention is a stacked and rolled combined type cutting three-phase three-dimensional stacked iron core structure. The semicircular iron core section formed by combining the trapezoidal material stacked part 1 and the rectangular material stacked part 2 is used as the core unit Frame 3, the three iron core single frames 3 are spliced in pairs in the vertical direction to form a three-dimensional iron core.

[0035] The stacked part 1 of the trapezoidal material adopts the longitudinal oblique line cutting of the rolled iron core, and then cuts horizontally according to the design angle and the length of the single silicon steel sheet to form multiple single silicon steel sheets, which are composed of multiple single silicon steel sheets in a stacked form The cross-section is trapezoidal stage, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com