Universal contact for nondestructive testing magnetic particle flaw detector

A magnetic particle flaw detection and nondestructive testing technology, which is applied in the direction of material magnetic variables, can solve the problems of unsatisfactory contact effect of sensitivity test pieces, insufficient detection sensitivity, and affecting detection sensitivity, so as to improve poor contact, increase sensitivity and applicable scenarios, and detect Conclusion Accurate and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

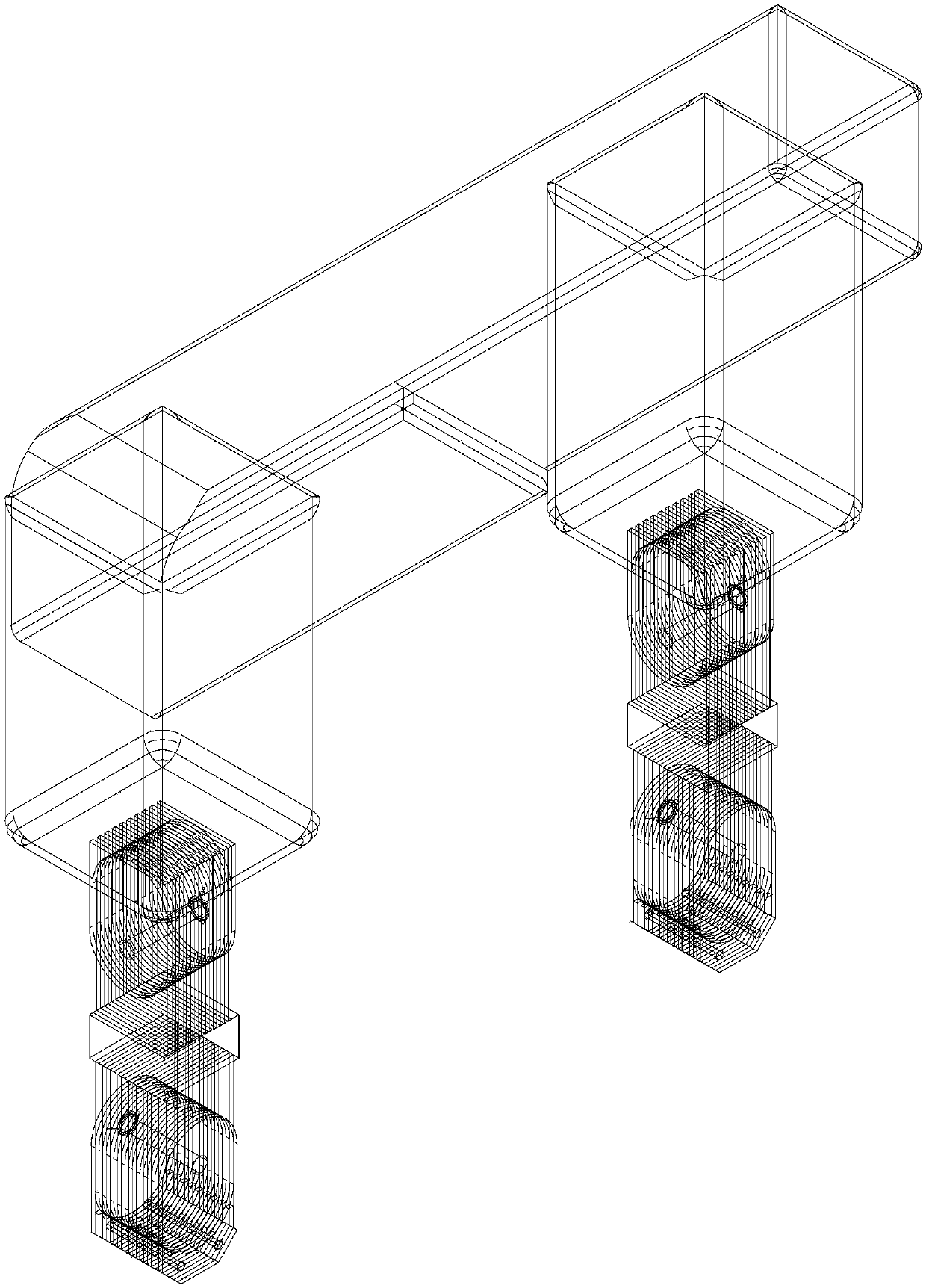

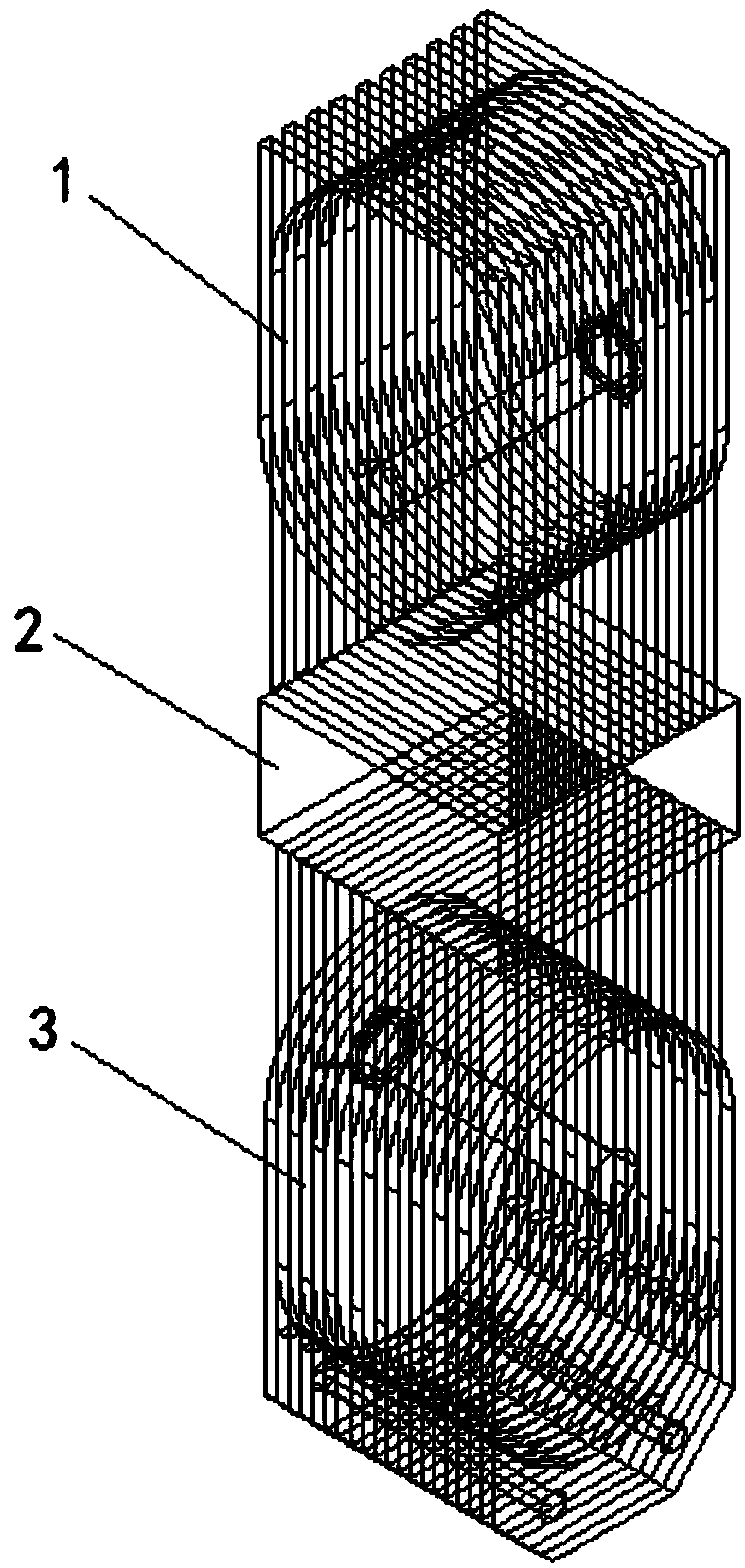

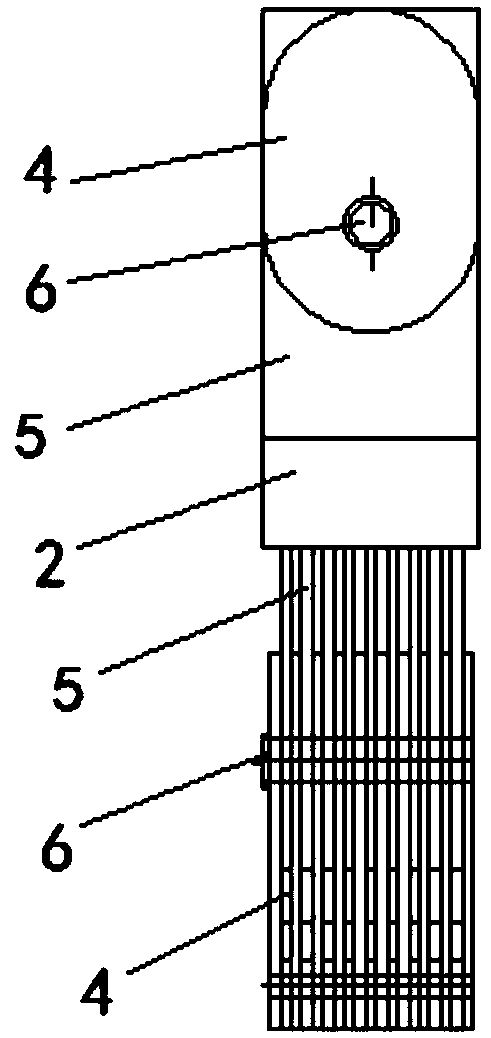

[0025] Such as Figure 2-4 As shown in the figure, a universal contact for non-destructive testing magnetic particle flaw detection machine includes an upper layer 1, a middle layer 2, and a lower layer 3 connected in sequence. Both the upper layer 1 and the lower layer 3 include a movable part 4 and a connecting part 5, one end of the connecting part 5 is fixedly connected to the middle layer 2, and the sheet-like structure at the other end of the connecting part 5 is stacked with the sheet-like structure of the movable part 4, and rotates through the rotating shaft 6 Connect, rotating shaft 6 is bolt, and one end of bolt is connected with horn nut, can carry out tightness adjustment. The rotating shafts 6 of the upper layer 1 and the lower layer 3 are perpendicular to each other. The sheet-like components of the lower layer 3 are fixed with screws.

[0026] The bottom end of the lower yoke contact is designed with front and rear chamfering, that is, it is processed with ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com