Modular assembly furniture system

A modular and furniture technology, applied in the field of furniture systems, can solve problems such as inability to replace components, inconvenient disassembly, and inability to modify, and achieve the effect of improving flexibility and solving inconvenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

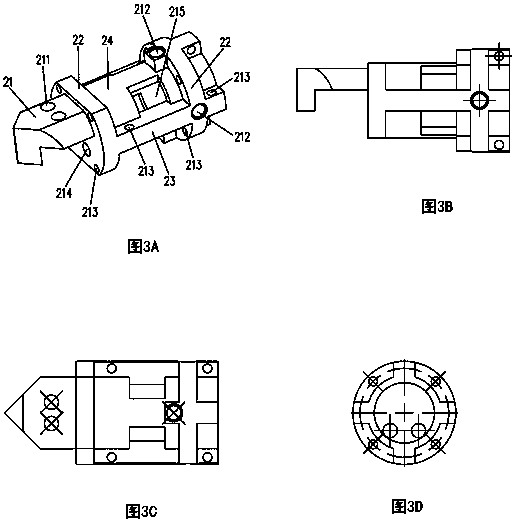

[0016] 1. Will image 3 The butt joint (2) of the rod in the figure 2 On the polygonal plate (11) of the connector (1) in the Figure 6 Insert the rivet (4) in the connecting head fixing hole (111) and the rod butt joint fixing hole (211) to fix the rod butt joint (2) and the connecting head (1); 2. Figure 5 Insert the rod (3) in the rod butt joint (2) into the fixing cylinder (24), align the rod butt joint fixing hole (212) and the rod fixing hole (311), and insert the rod with the rivet (4) In the butt joint fixing hole (212) and the rod fixing hole (311), fix the rod butt joint (2) and the rod (3); 3. Figure 7 The plate (5) in is placed on the dowel bar (23) of the bar butt joint (2), aligns the bar butt joint fixing hole (213) and the plate fixing hole (511), and inserts the rivet (4) into the bar In the butt joint fixing hole (213) and the plate fixing hole (511), the rod butt joint (2) and the plate (5) are fixed. Repeat the above actions to complete furniture of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com