Material binding device for industrial design

A technology of industrial design and support table, which is applied in binding and other directions, can solve the problems of inability to achieve the binding effect, cumbersome operation of the binding machine, and affect the binding effect, and achieve the effects of novel design, increased binding quality, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

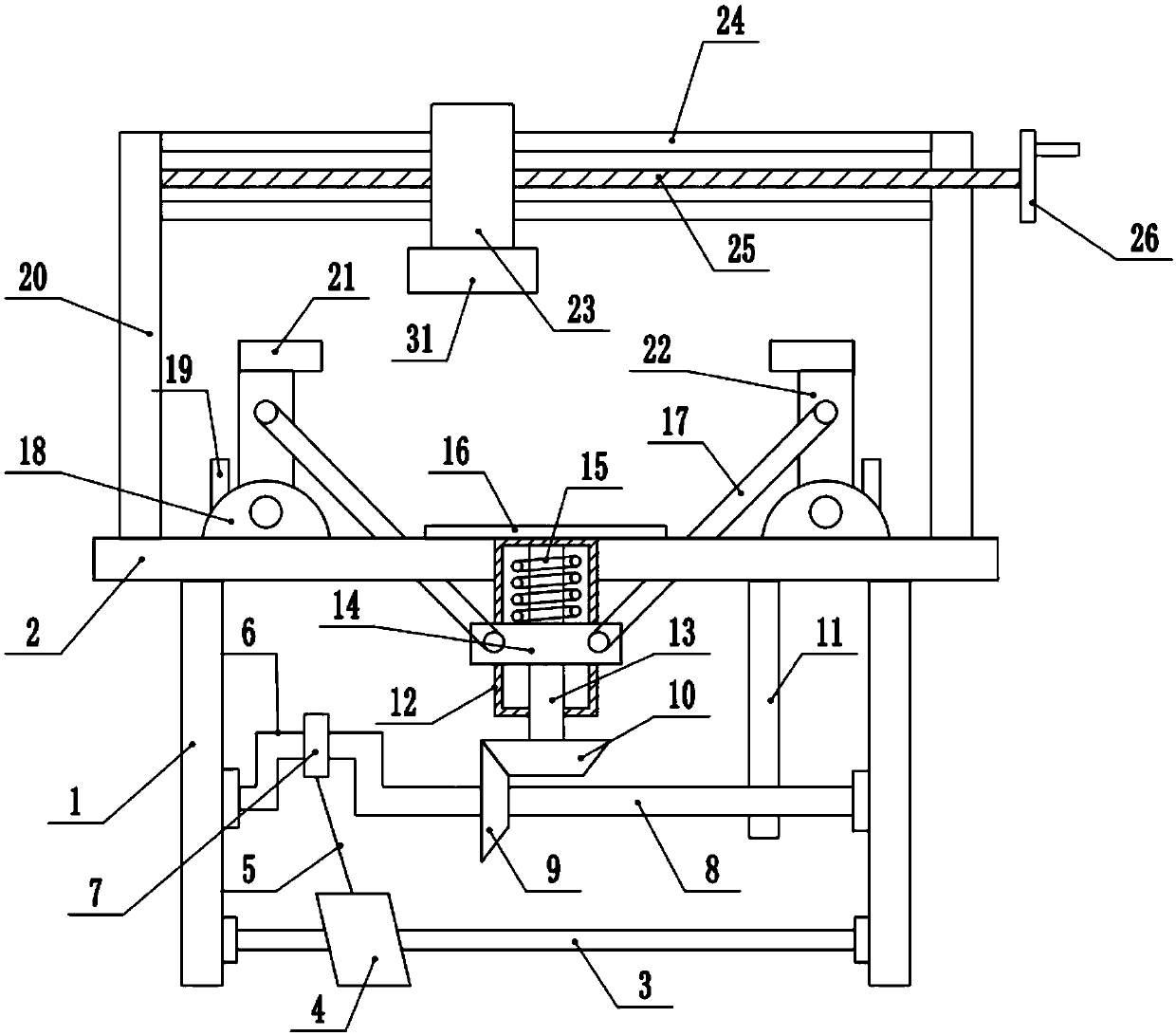

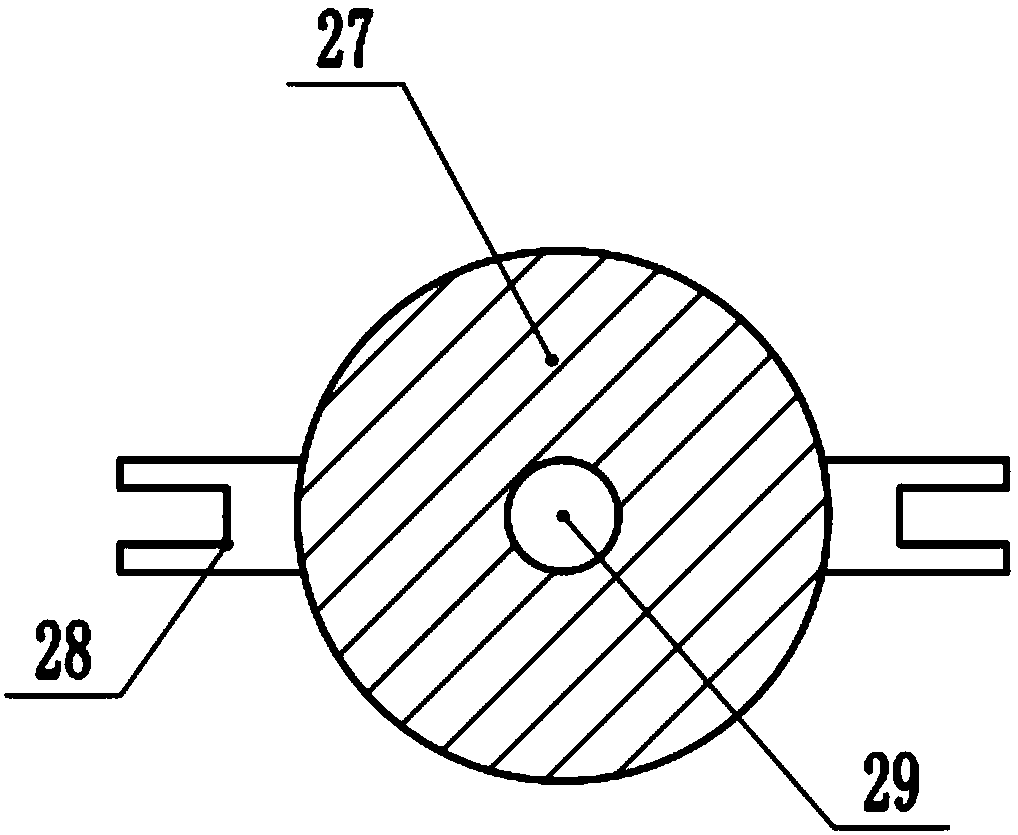

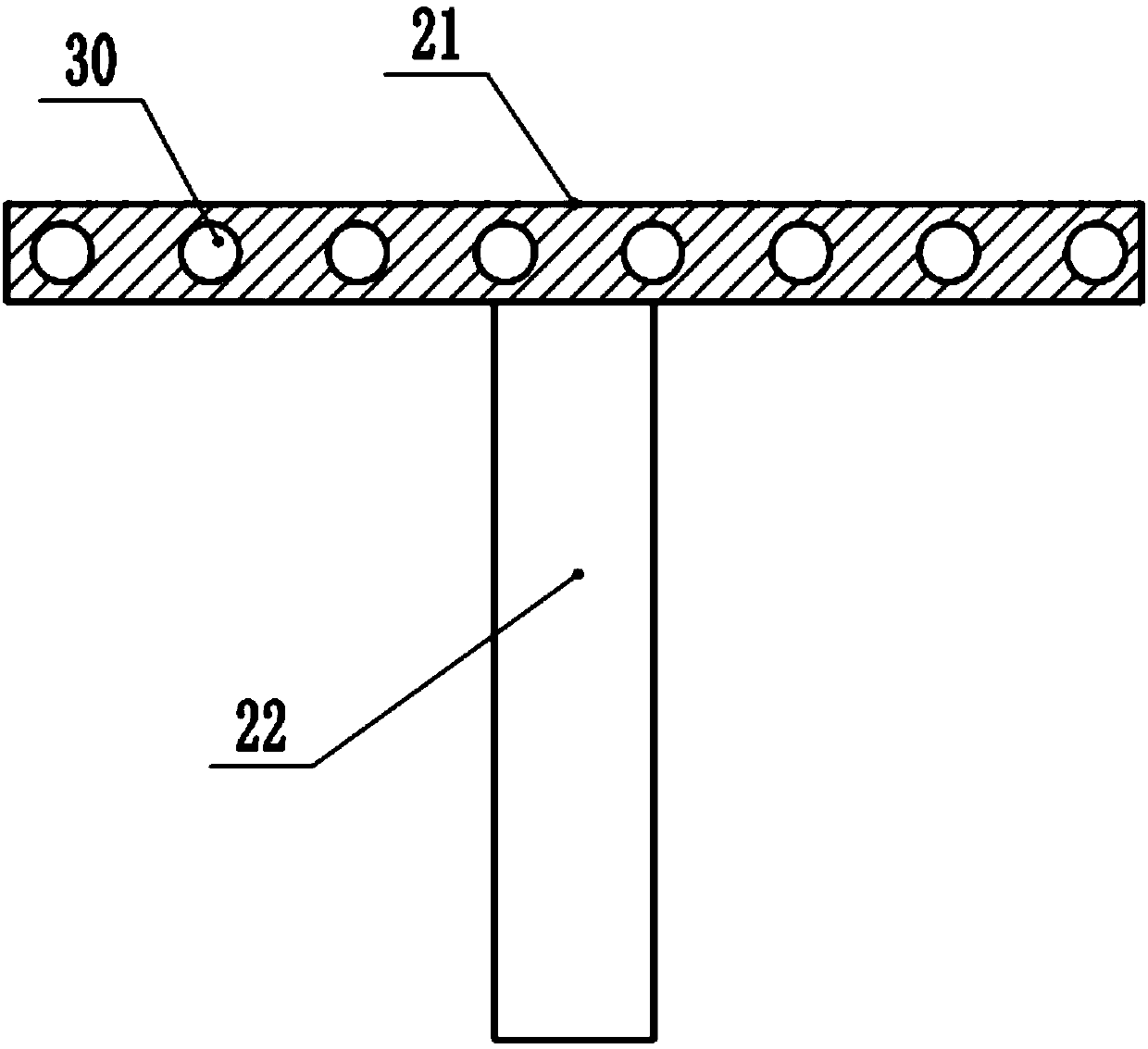

[0027] refer to figure 1 , in an embodiment of the present invention, a material binding device for industrial design, comprising a support leg 1 and a support table 2 fixed to the upper end of the support leg 1, a binding table 16 is installed in the middle of the upper end of the support table 2, for placing Industrial design material, a rotating shaft 8 is installed between the supporting legs 1, and a limit frame 11 is installed in the middle of the right end of the rotating shaft 8, which is used to limit the rotation of the rotating shaft 8 and avoid shaking during its rotation , and then ensure the accurate meshing between the driving gear 9 and the driven gear 10, the limit frame 11 is fixed on the right side of the lower end of the support table 2, the driving gear 9 is installed in the middle of the rotating shaft 8, and the middle part of the left end of the rotating shaft 8 is installed Crank 6, the middle part of crank 6 is equipped with sliding sleeve 7, and slid...

Embodiment 2

[0031] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that stoppers 19 are installed on both ends of the fixed block 18, and the rotation angle of the fixed block 18 is limited by setting the stoppers 19, Further ensure device reliability.

[0032]In the present invention, when working, put the materials that need to be bound on the binding table 16 after sorting out, then step on the pedal 4 to rotate, so that the rotating shaft 8 rotates, and then the driving gear 9 and the driven gear 10 are meshed with the screw mandrel 13 Rotate to make the lifting mechanism 14 move down, and then make the action of the pull rod 17, so that the rotating rod 22 drives the clamping block 21 to move down, and the edge of the industrial design material is clamped and fixed, and then the rotating handle 26 is turned to make the screw 25 is rotated so that the guide block 23 drives the binding head 31 to move to a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com