Automatic vegetable cutter

An automatic vegetable cutting machine and driving mechanism technology, applied in metal processing, grain processing, etc., can solve the problem of not being able to meet the cutting degree of various raw materials at the same time, achieve the effects of simple structure, prolonging service life, and ensuring cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing description and specific embodiment, the present invention will be described in further detail:

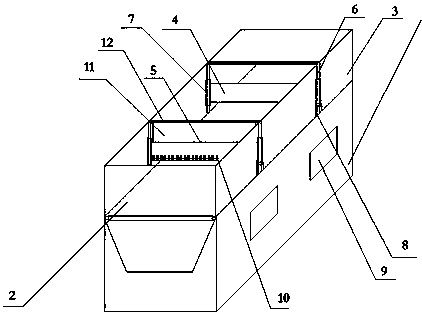

[0011] see figure 1 , an automatic vegetable cutting machine, comprising a base 1 and a transfer table 2, the transfer table 2 is located on the base 1, side plates 3 are arranged on both sides of the transfer table 2, and rough cutting blades are arranged on the transfer table 2 4 and the fine cutting blade 5, the side plate 3 is provided with a slide rail 6, the slide rail 6 is provided with a linkage rod 7, the rough cutting blade 4 is fixed on the transfer table 2 through the linkage rod 7 on the side plate 3, and the linkage The rod 7 is connected with the driving mechanism 9 in the base 1 through the transmission rod 8, and the fine cutting blade 5 is fixed by another set of linkage rods 7. The fine cutting blade 5 is hollow, and the bottom is provided with a cutting hole 10. A baffle 11 is provided, and the baffle 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com