Bearing and method for monitoring wear and/or measuring load

A technology for bearings and bearing rings, used in bearings and for monitoring wear and/or measuring loads, which can solve problems such as high labor costs, radial and axial components that cannot be clearly separated from each other, and minimize downtime , simple wear monitoring and/or load measurement, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

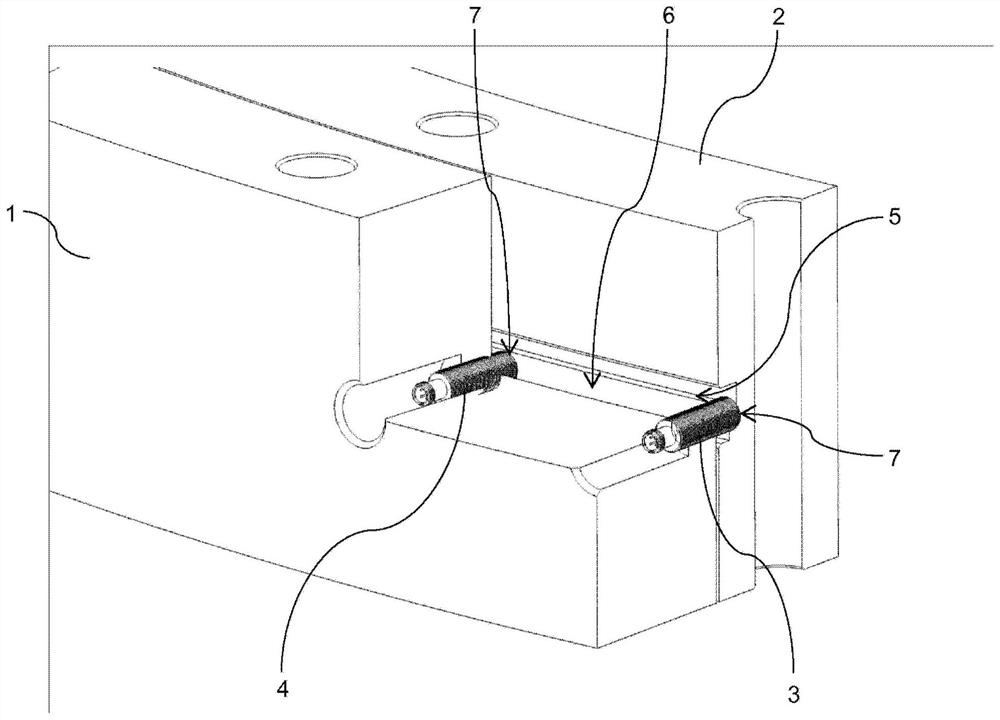

[0026] In the various figures, the same parts are always indicated by the same reference numerals and are therefore usually only cited or mentioned once.

[0027] figure 1 A perspective cross-sectional view of a bearing according to an exemplary embodiment of the present invention is shown. The bearings here are slewing rings, such as but not limited to those used in wind turbines. Such a swivel ring has, for example, an outer diameter of approximately 2.5 m. Of course, other fields of application and other bearing designs, such as having intermeshing teeth instead of rolling elements or oscillating bearings instead of rolling bearings, are also possible.

[0028] The bearing has a static, ie fixed or stationary, first bearing ring 1 (here outer ring 1 ) and a second bearing ring 2 (here inner ring 2 ) which is arranged concentrically in outer ring 1 . Here, the inner ring 2 is rotatable about a rotational or longitudinal axis passing through the center of the inner ring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com