Spin forming machine and forming method for manufacturing wheels

A molding method and molding machine technology, applied in rims, transportation and packaging, vehicle parts, etc., can solve problems such as high, time-consuming and cost-effective, and achieve the effect of increasing the diversity of shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

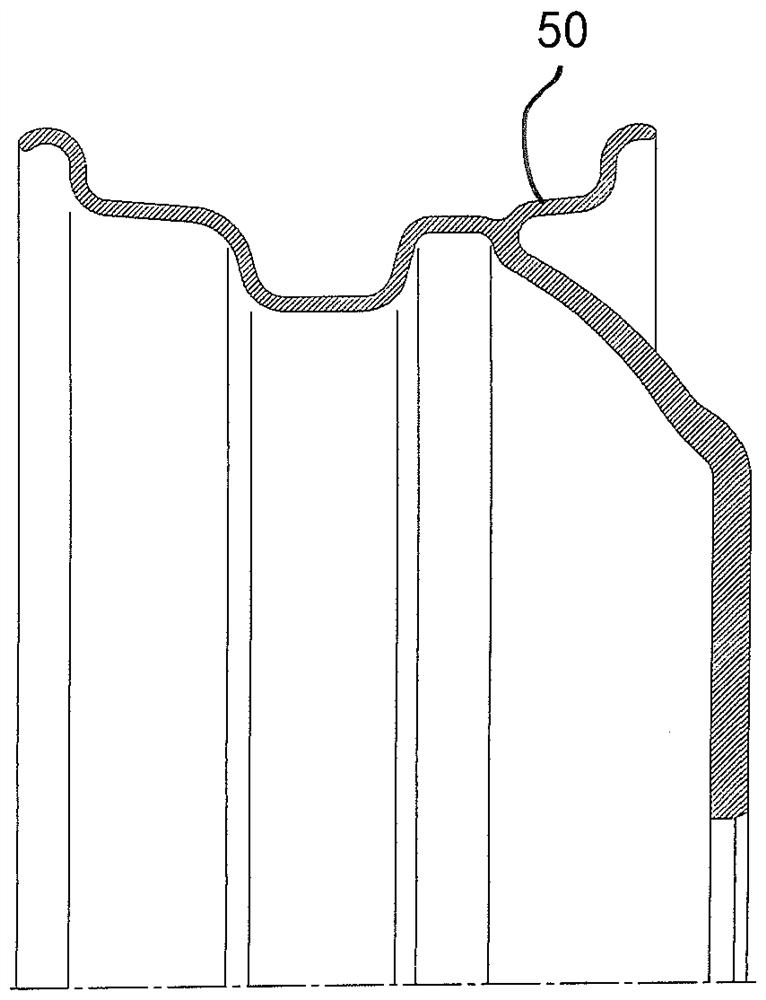

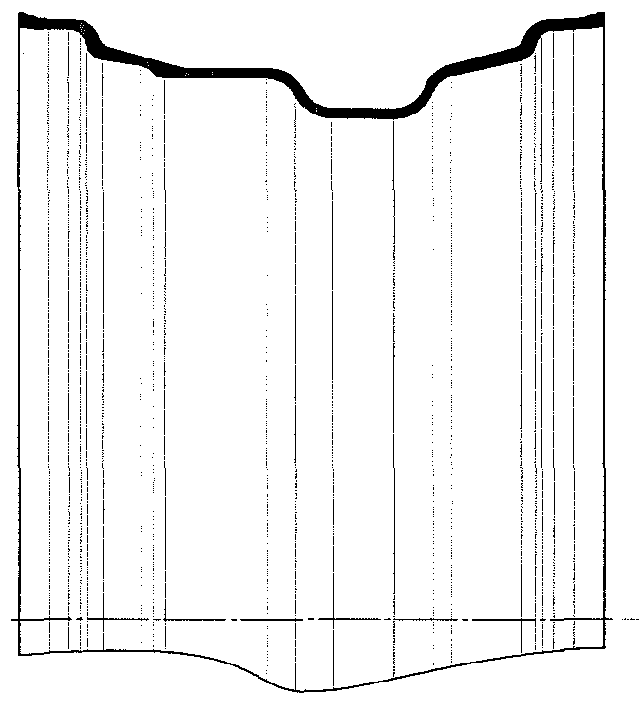

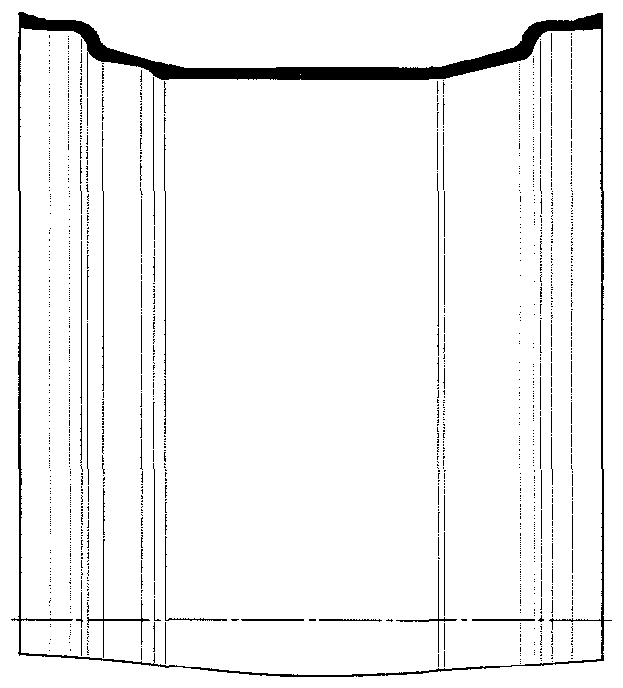

[0036] The spin forming machine 10 according to the invention has a spinning mandrel 20 and an opposite counter mandrel 12, between which the workpiece 5 is axially clamped by means of a disc-shaped hub region 6 with a central fixed Core hole and surrounding area to be formed 7. The mating mandrel 12 and the spinning mandrel 20 are rotatably mounted on drive flanges 16 and 17, respectively, and are connected to one, preferably each, not shown rotary drives, wherein the vertical shafts can be rotated during the forming process. The straight central axis of rotation 2 drives in rotation the spinning mandrel 20 , the counter mandrel 12 and the clamped workpiece 5 .

[0037] The spinning mandrel 20 has a central base support 22 at the free end of which an annular or disk-shaped front element 24 is releasably fastened by means of bolts. As with the opposite mating mandrel 12 (provided with the profiled surface 14 ), the front element 24 is adapted to the shape of the workpiece 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com