Deep channel whole-domain testing method

A test method and deep tunnel technology, applied in the field of tunnel lining segments, can solve the problem that the loading device is difficult to meet the high-precision test requirements

Active Publication Date: 2019-04-26

SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

View PDF9 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned loading device is diffi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

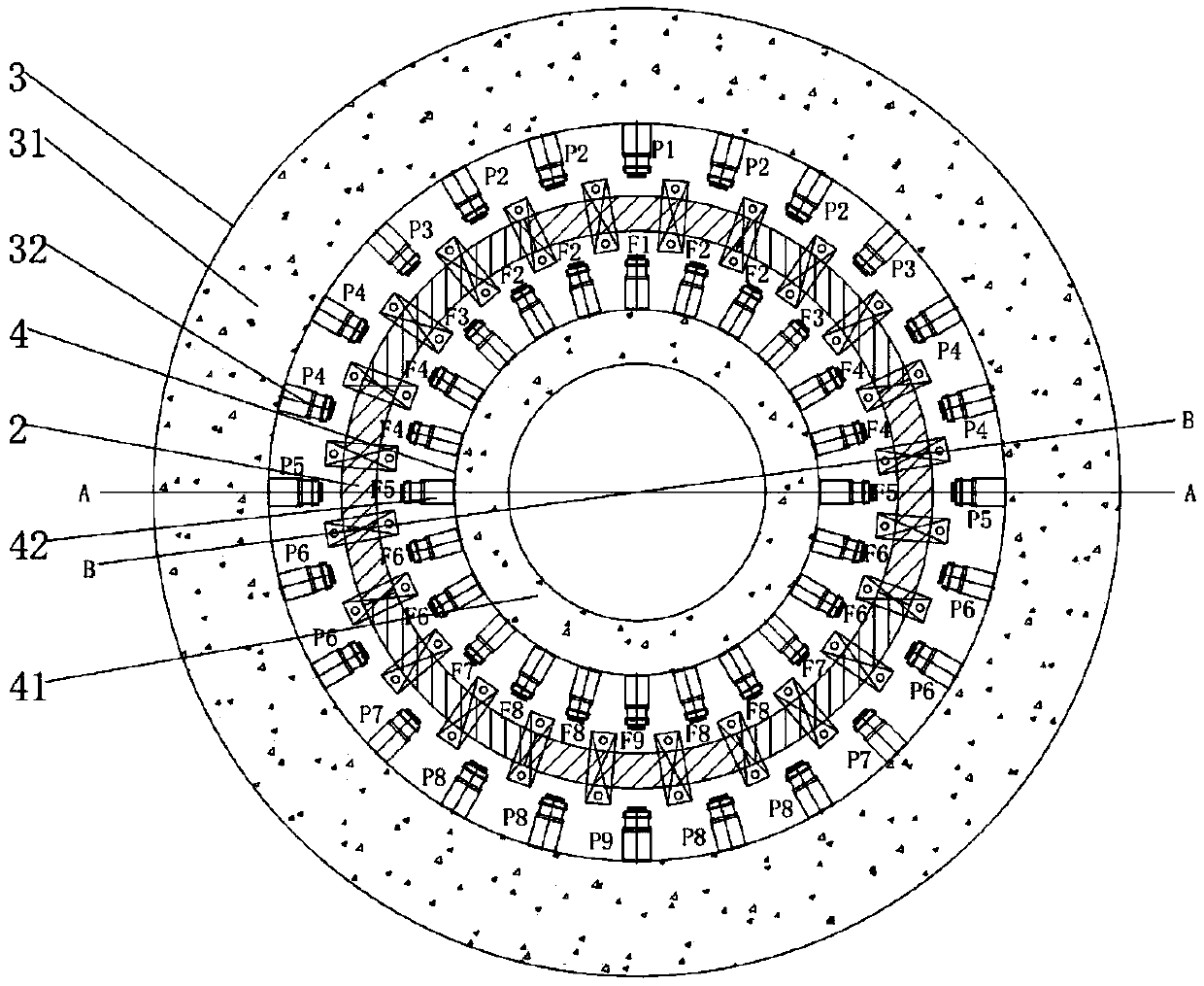

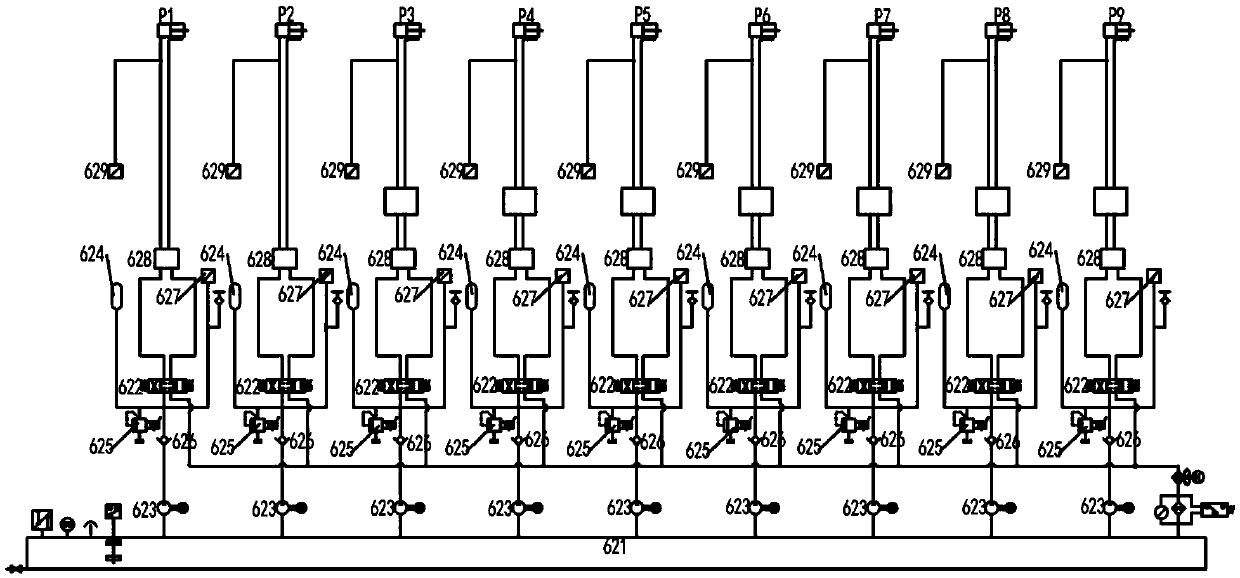

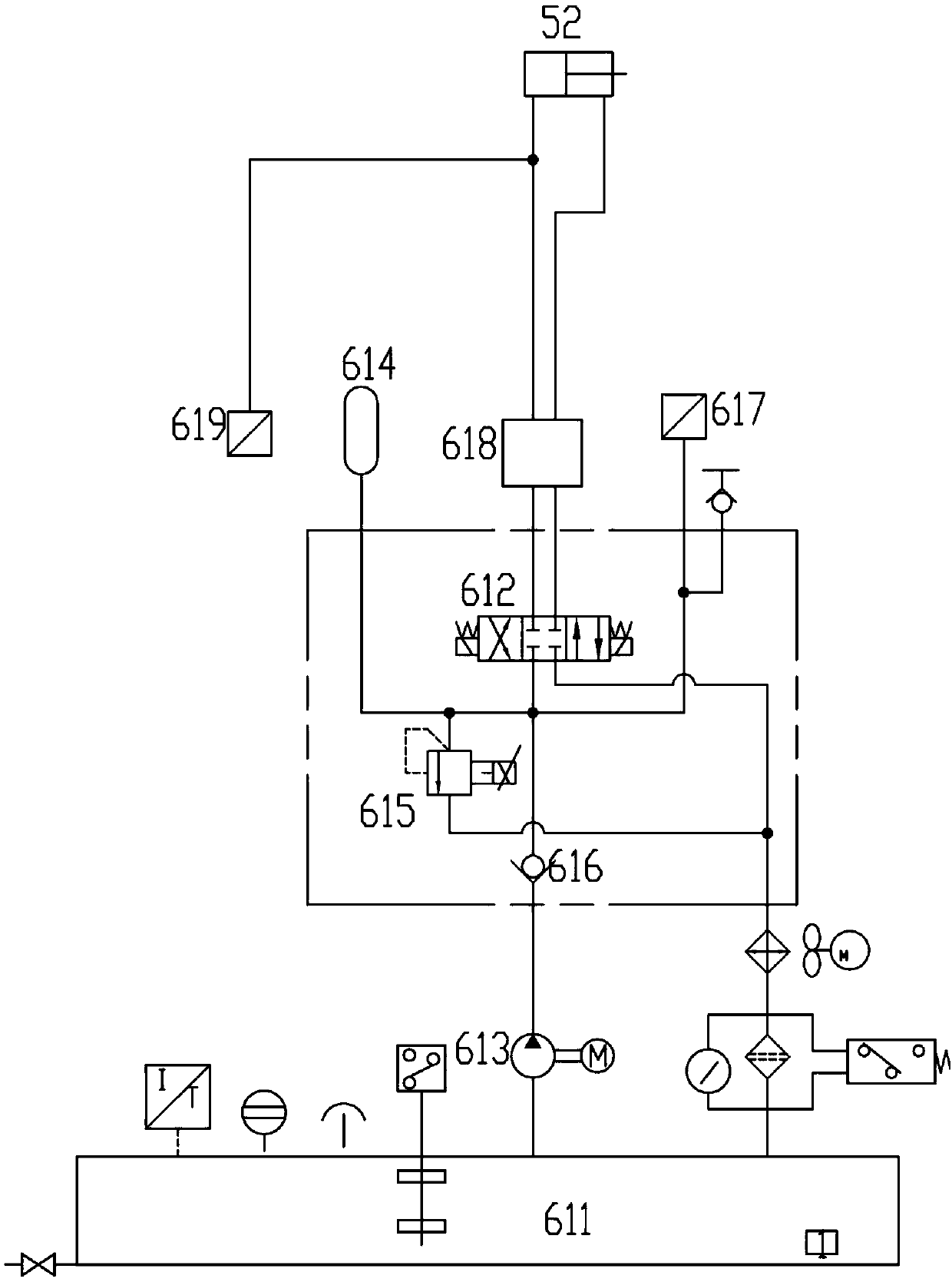

The invention provides a deep channel whole-domain testing method. The method includes the following steps of firstly, calculating the mechanical characteristic and selecting the loading scheme according to the surrounding rock pressure which an experimental lining segment ring should bear at the theoretical burying depth and the dead weight of the lining segment ring; secondly, preparing a longitudinal loading counterforce frame, an outer side radial loading counterforce frame and an inner side radial loading counterforce frame, and preparing the experimental lining segment ring; thirdly, installing oil cylinders at all corresponding measuring points on the longitudinal loading counterforce frame, the outer side radial loading counterforce frame and the inner side radial loading counterforce frame based on measuring points selected in the first step, dividing the outer side oil cylinders and the inner side oil cylinder into a plurality of load groups according to the loading scheme, and driving the oil cylinders of each load group by an ejecting hydraulic device; fourthly, driving one or more of the longitudinal oil cylinders, the outer side oil cylinders and the inner side oil cylinders according to the loading scheme, and conducting stepped loading on the experimental lining segment ring. The method is high in precision and can effectively restrain the fine adjustment of a PID controller.

Description

technical field [0001] The invention relates to a tunnel lining segment, in particular to a test method for the whole ring of a deep tunnel. Background technique [0002] After the subway tunnel is completed and put into operation, with the continuous accumulation of operation time, due to the inherent quality defects of the subway lining, it is easy to cause lining cracking, falling off, concrete carbonization, water leakage and other diseases. Among them, the cracking of the lining structure of subway tunnels is the most common disease, and it is also the direct cause of various diseases such as leakage, mud turning and block falling in the tunnel. [0003] There are many reasons for the formation of tunnel lining cracks and are very complicated. Therefore, to explore the causes, development and overall damage of tunnel lining cracks, the commonly used test methods are in-situ tests or indoor model experiments. The former is more authentic and reliable, but the experiment...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M99/00

CPCG01M99/007

Inventor 沈浩曾华陶镛光

Owner SHANGHAI ELECTRICAL HYDRAULICS & PNEUMATICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com