An automatic retractable vortex generator system based on wind turbine blades

A technology of vortex generators and wind turbine blades, which is applied to wind turbines, wind turbines, and wind power generation in the same direction as the wind. It can solve problems such as resistance, complex wind turbine power generation environment, and increased load on wind turbine blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The automatic retractable vortex generator system based on wind turbine blades of the present invention will be described in more detail below in conjunction with the schematic diagram, wherein a preferred embodiment of the present invention is represented, and it should be understood that those skilled in the art can modify the present invention described here, and The advantageous effects of the invention are still achieved. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

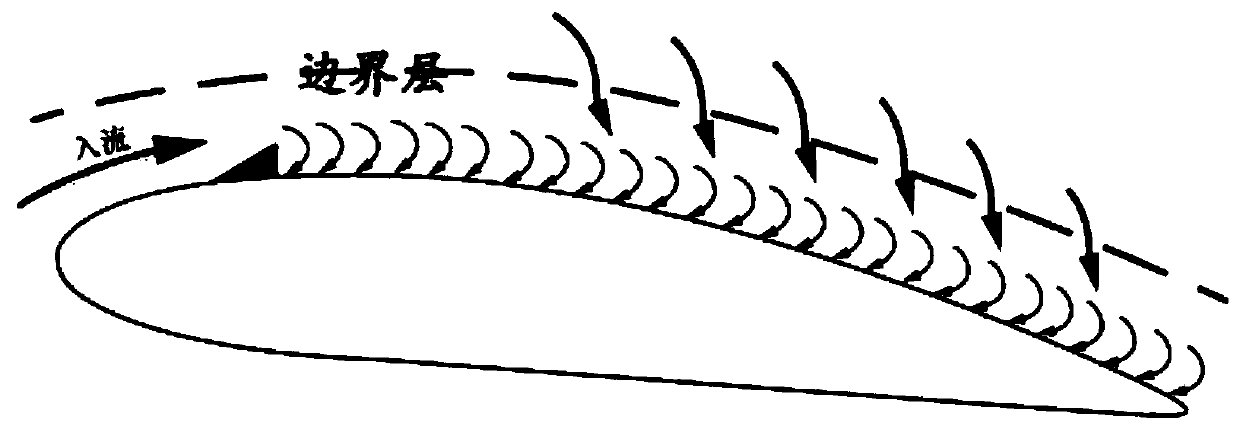

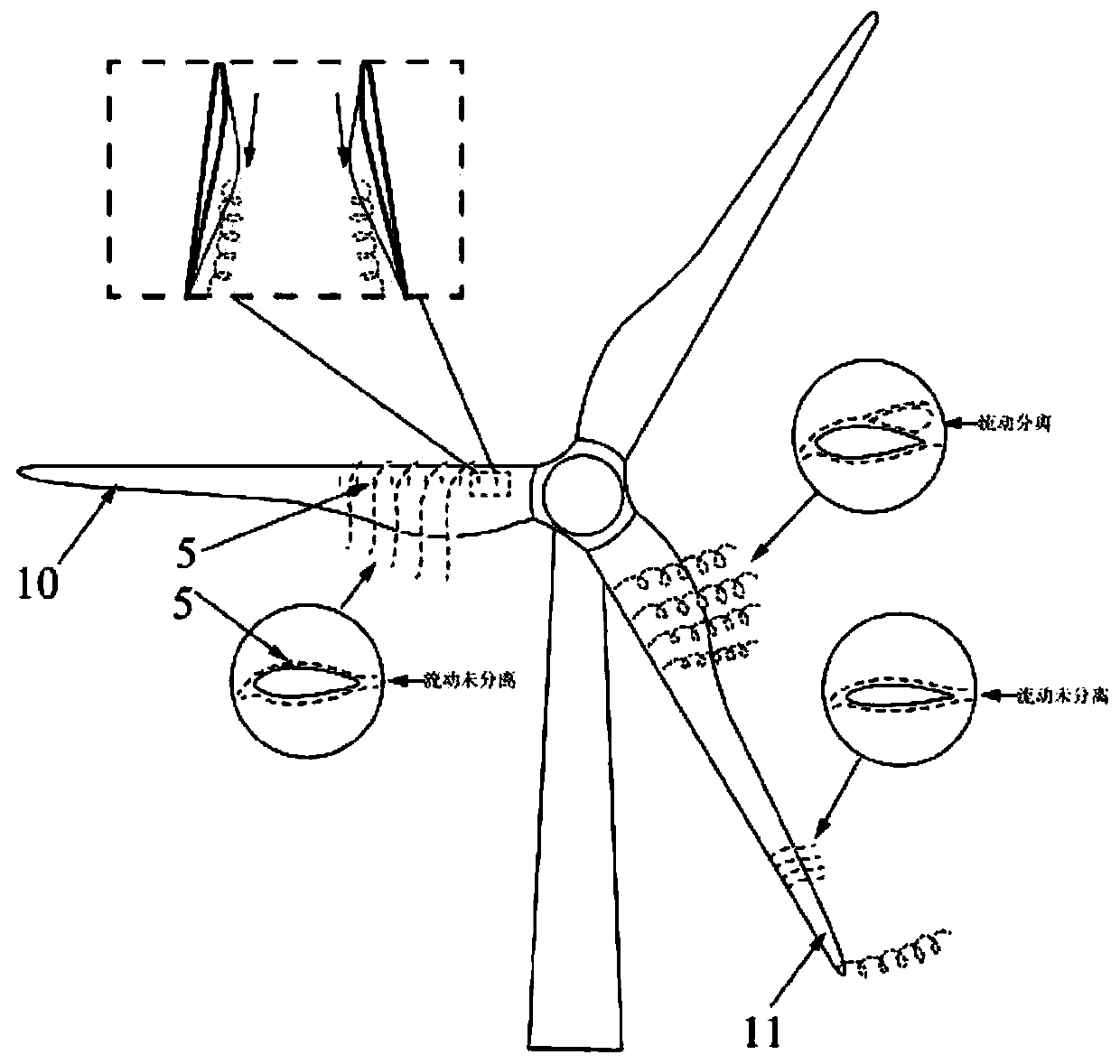

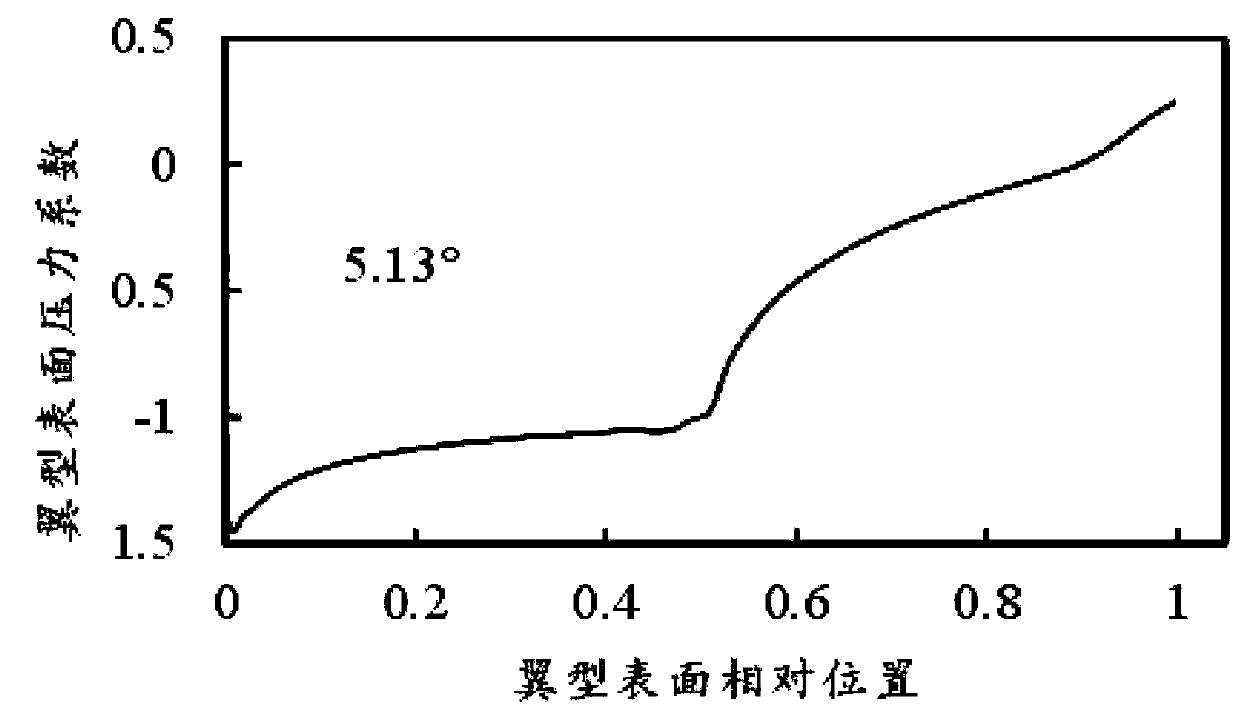

[0032] In this example, the study found that when the airfoil has a small angle of attack ( Figure 3a ) That is, when the flow separation does not occur on the surface of the wind turbine blade 1, the pressure on the upper surface will continue to increase from the middle to the trailing edge. And when the angle of attack is large ( Figure 3b ) After the flow separation occurs, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com