Method for fully recycling anions and cations from microetching waste liquid

An anion-cation, micro-etching technology, applied in the field of ammonium sulfate crystallization and copper sulfate crystallization production, can solve the problems of low value and high hazard of micro-etching waste liquid

Active Publication Date: 2019-04-26

SHANGHAI TIANHAN ENVIRONMENTAL RESOURCES CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] Due to the low value and high hazard of micro-etching waste liquid, the existing resource disposal methods of micro-etching waste liquid cannot meet the increasingly stringent environmental protection requirements, and there is a shortcoming that anion sulfate radicals are di

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

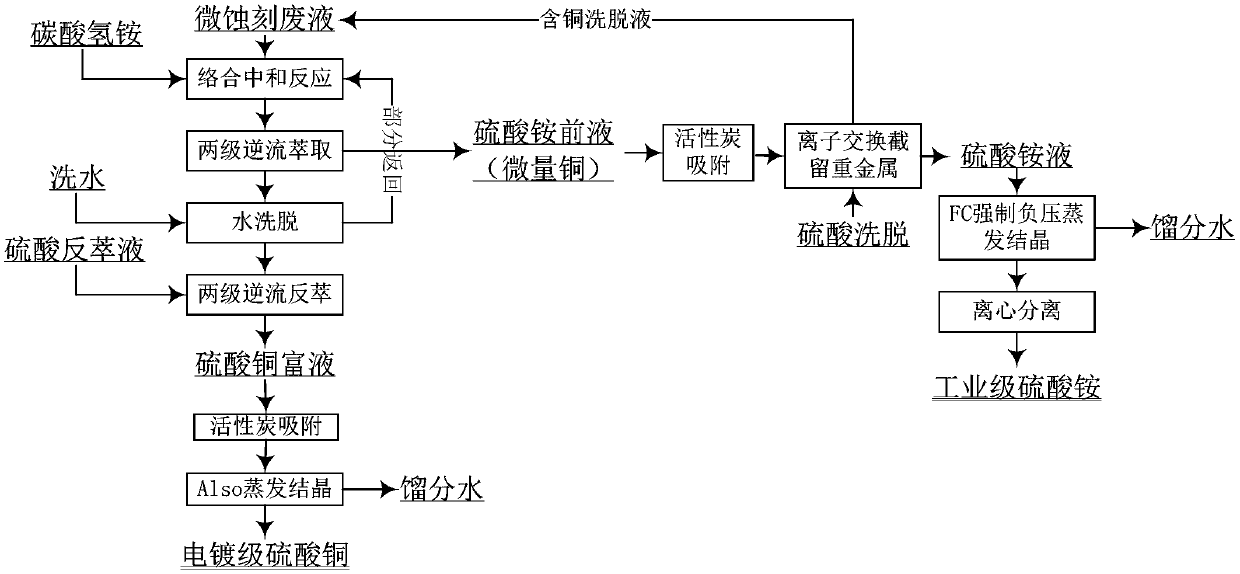

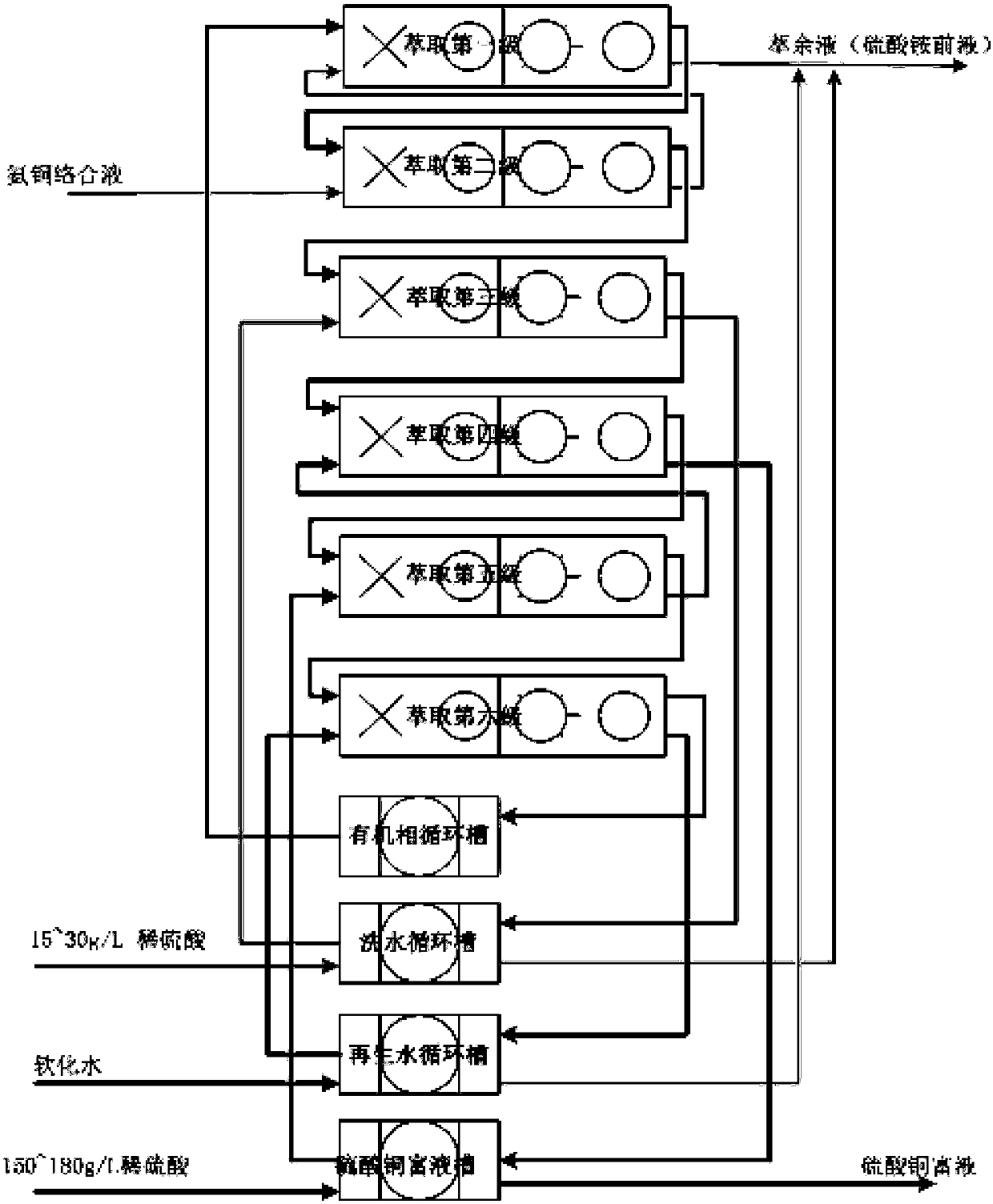

The invention discloses a method for fully recycling anions and cations from microetching waste liquid. The method comprises the following steps: (1), adjusting the pH value of the microetching wasteliquid to be treated to 2.5-3.5; (2), extracting the microetching waste liquid by using extracting equipment to produce a raffinate, washing water and copper-rich liquid; (3), mixing the washing waterwith the raffinate, and then performing cotton core filtration, activated carbon filtration and ion exchange resin filtration to remove waste organic matters and intercept residual heavy metal ions to obtain a colorless ammonium sulfate solution; (4), then, crystallizing through evaporative concentration under negative pressure and at low temperature to produce ammonium sulfate crystals; and (5),finally, performing evaporative concentration under negative pressure and crystal growth to produce granular copper sulfate pentahydrate crystals. According to the method, liquid operation is performed and a precipitate filtration need is avoided in the whole process, a requirement on almost no residual copper ions in the raffinate can be met, the quality of the product crystallized copper sulfate can reach an electroplating pure grade index, the anionic sulfate is finally produced in the form of ammonium sulfate, and the demand on an ammonium sulfate product in the national standard is met.

Description

technical field [0001] The invention relates to the field of resource utilization of micro-etching / browning waste liquid in the printed circuit board industry, in particular to a resource utilization of micro-etching waste liquid or browning waste liquid produced in the printed circuit board industry to produce copper sulfate Method of crystallization and ammonium sulfate crystallization. Background technique [0002] As a basic metal, copper is currently one of the most widely used and important metals in the world; its conductivity is second only to silver among all metal elements, and it is the foundation of conductors in the electronics industry. Different from the copper consumption structure of developed countries such as the United States, the industries with large consumption of copper products in my country mainly include: power cables, electronic communications, household appliances, machinery manufacturing, construction industry, transportation, national defense, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G3/10C01C1/24

CPCC01C1/24C01G3/003C01G3/10C01P2006/80

Inventor 卢正杰张奎何坤鹏

Owner SHANGHAI TIANHAN ENVIRONMENTAL RESOURCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com