Feeding device of printed circuit board hole detection machine

A printed circuit and material moving technology, which is applied to conveyors, destacking of objects, conveyor objects, etc., can solve the problems of inaccurate feeding position, slow speed, and difficulty in quality control of printed circuit boards, so as to improve work efficiency. Efficiency, reduce manpower output, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

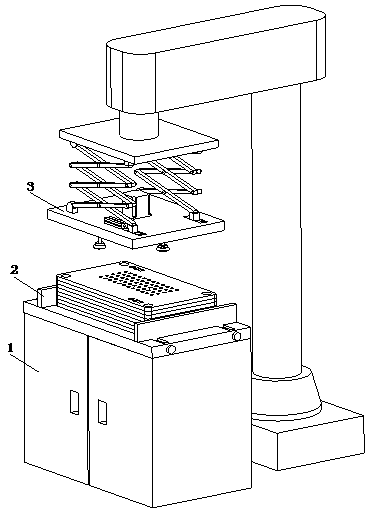

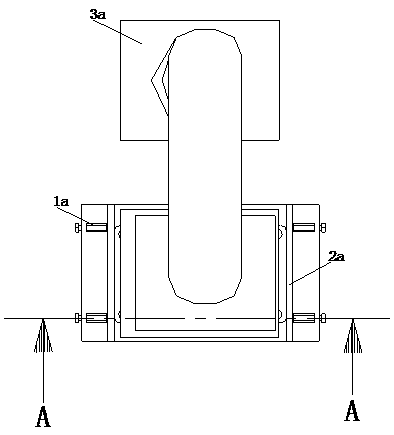

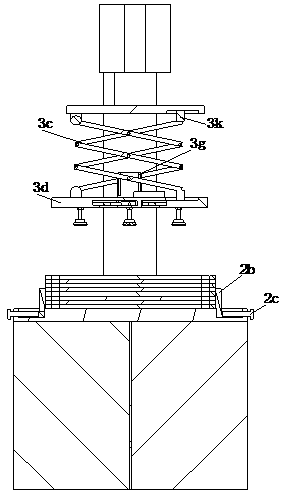

[0026] refer to Figure 1 to Figure 8 The feeding device of a printed circuit board hole inspection machine shown includes a working cabinet 1, a limiting mechanism 2 and a feeding mechanism 3, the working cabinet 1 is a rectangular structure, and the limiting mechanism 2 is arranged on the working cabinet 1, the feeding mechanism 3 includes a support frame 3a and a material shifting part 3b installed on the support frame 3a and located directly above the work cabinet 1, and the limit mechanism 2 includes two symmetrically arranged on the top of the work cabinet 1 Each limiting part 2a includes a limiting plate 2b and two adjusting bolts 2c that are installed on the bottom of the limiting plate 2b and can move back and forth along the length of the work cabinet 1, and the support frame 3a is arranged on On the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com