Automatic separating mechanism capable of enabling paper strips to be automatically separated, for bobbin paper stripping machine

An automatic separation and bobbin paper technology, which is applied in metal processing and other directions, can solve the problems of paper strip damage, time-consuming and labor-intensive separation, troublesome and troublesome separation, etc., and achieve the effect of easy production, easy assembly, and beneficial to subsequent operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

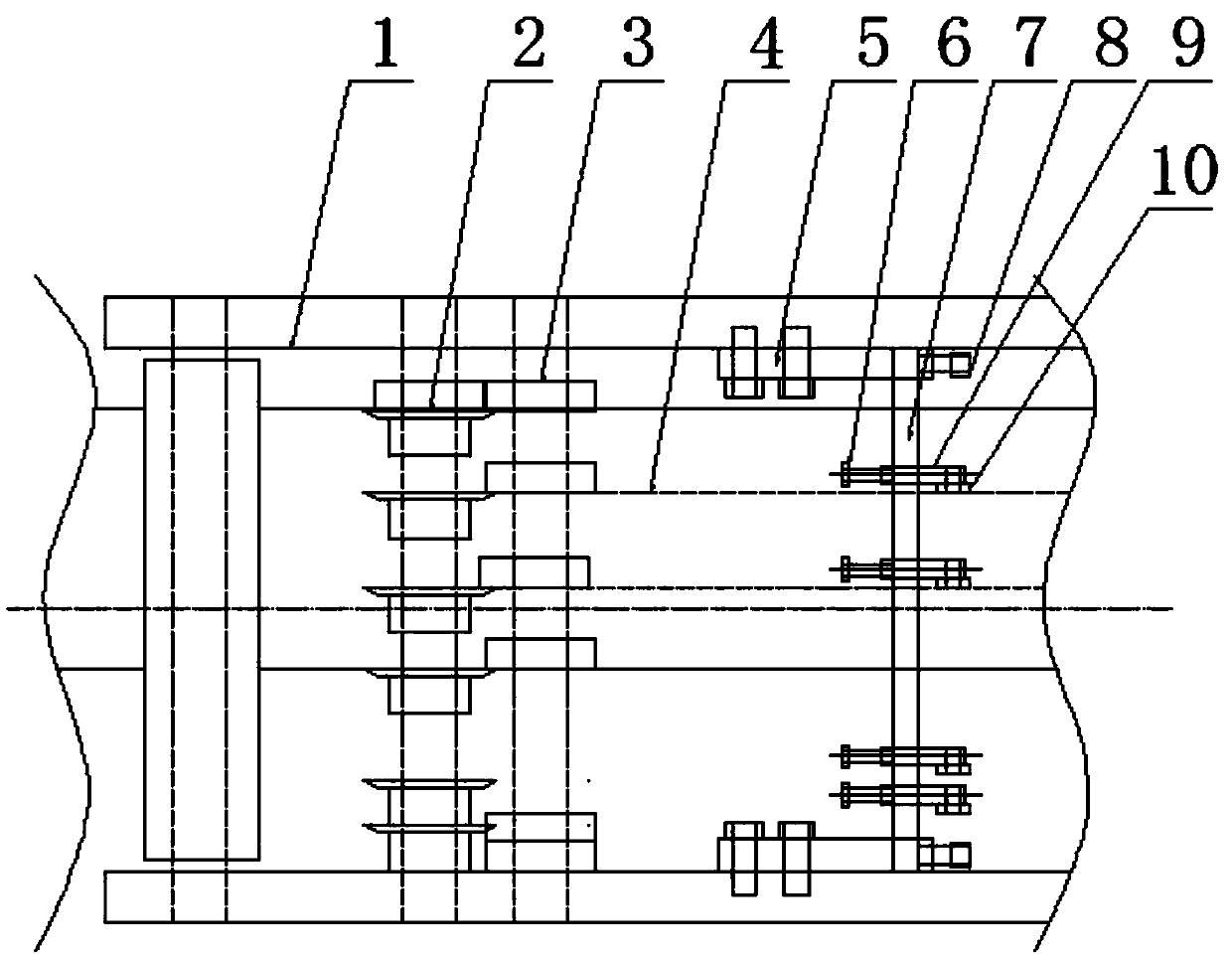

[0017] An automatic separation mechanism for bobbin paper slitting machine that can automatically separate paper strips. It is composed of bracket 5, support shaft 7, locking screw 6, and pressing roller group. The bracket is symmetrically fixed on the bobbin paper slitting machine. 1, the fulcrum is set on the upper end of the support, the locking screw is set on the top of the support, and the roller group is set on the fulcrum. The support has a fulcrum assembly hole on its upper end, and a locking screw hole on its upper top perpendicular to the fulcrum assembly hole.

[0018] There are multiple roller groups, and multiple roller groups are arranged on the support shaft as required. In this embodiment, there are four, all of which are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com