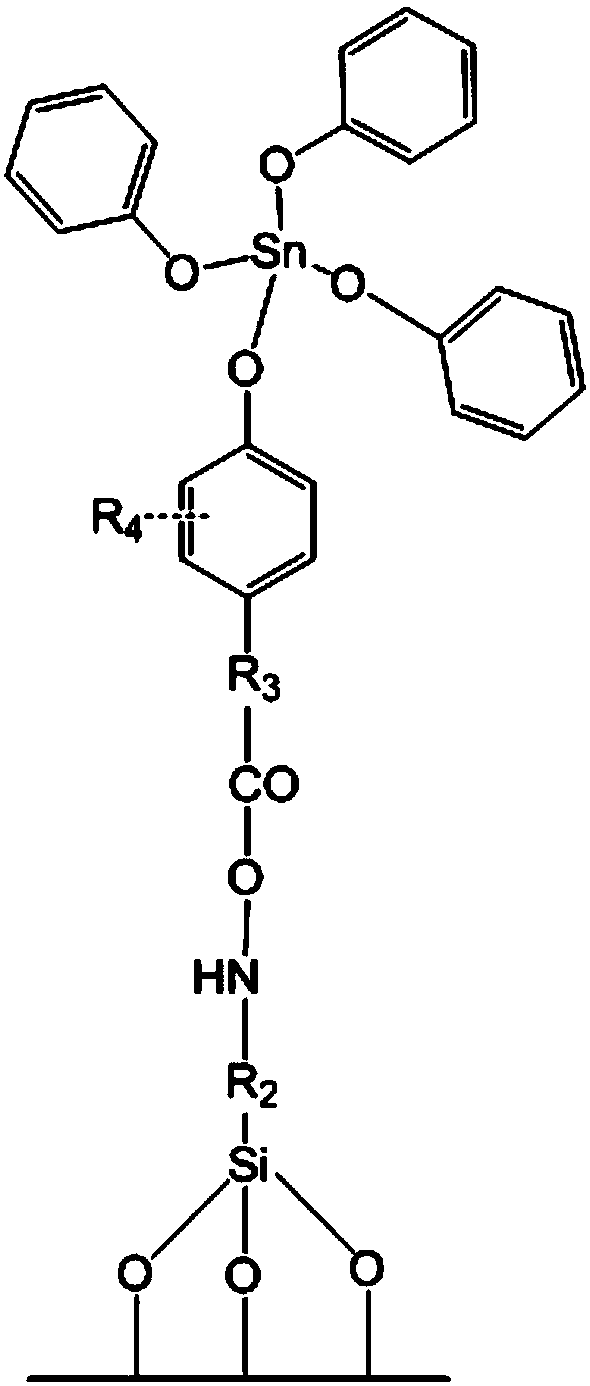

Preparation and application of monodisperse solid catalyst for preparing diphenyl carbonate through interesterification

A technology of diphenyl carbonate and dimethyl carbonate is applied in the field of preparation and application of a monodispersed solid catalyst for preparing diphenyl carbonate by transesterification, and can solve problems such as low activity and selectivity of heterogeneous catalysts, Achieve the effect of solving easy inactivation, avoiding loss, and strong interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

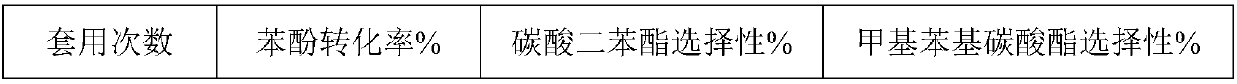

Examples

Embodiment 1

[0030] Take 50g of silica balls and add them to 500ml of toluene, heat to reflux and add 0.01mol aminopropyltriethoxysilane, after reflux for 2h, cool, filter and wash with absolute ethanol. Prepare 0.1 mol p-hydroxybenzoic acid solution, add the modified carrier, heat and stir for 8 hours. Filter, wash with ethanol, immerse in an aqueous solution containing 0.1mol tin tetrachloride, stir for 4 hours, add excess phenol, filter, wash with dimethyl carbonate, and dry to obtain catalyst sample S1 for reaction.

Embodiment 2

[0032] Take 50g of activated carbon and add it to 500ml of ethanol, add 0.01mol aminopropyltriethoxysilane after heating to reflux, and after reflux for 2h, cool, filter, and wash with absolute ethanol. Dissolve 0.1 mol of o-hydroxybenzoic acid, add the modified carrier, and heat and stir for 8 hours. After filtering, washing with ethanol, immersing in an aqueous solution containing 0.1 mol of tin nitrate, stirring for 4 hours, adding excess phenol, filtering, washing with dimethyl carbonate, and drying to obtain a reaction catalyst sample S2.

Embodiment 3

[0034] Take 50g of silica balls and add them to 500ml of dichloromethane, heat to reflux and add 0.01mol aminopropyltriethoxysilane, after reflux for 2h, cool, filter and wash with dichloromethane. Dissolve 0.1 mol of p-hydroxybenzoic acid, add the modified carrier, heat and stir for 8 hours. Filter, wash with ethanol, immerse in a chloroform solution containing 0.1 trimethylstannane, stir for 4 hours, add excess phenol, filter, wash with dimethyl carbonate, and dry to obtain a reaction catalyst sample S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com