Pot seedling pickup system

A technology for top seedlings and pot seedlings, which is applied in the field of crop transplanting, can solve the problems of affecting the transplanting work efficiency, the growth of pot seedlings, the unstable performance of the control system, and the low degree of intelligence, so as to reduce the seedling missed planting rate and eliminate the Top plate phenomenon, the effect of improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

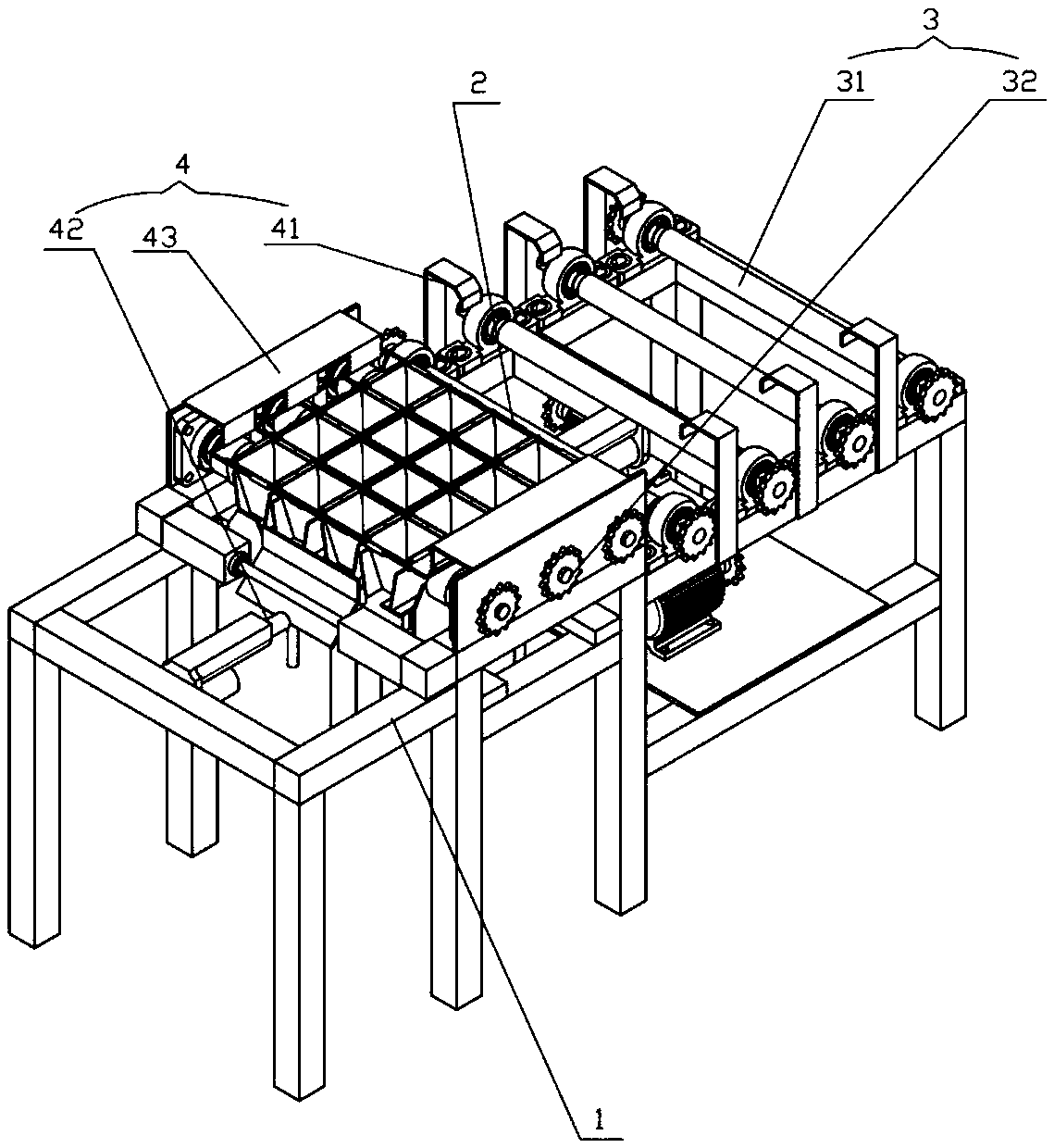

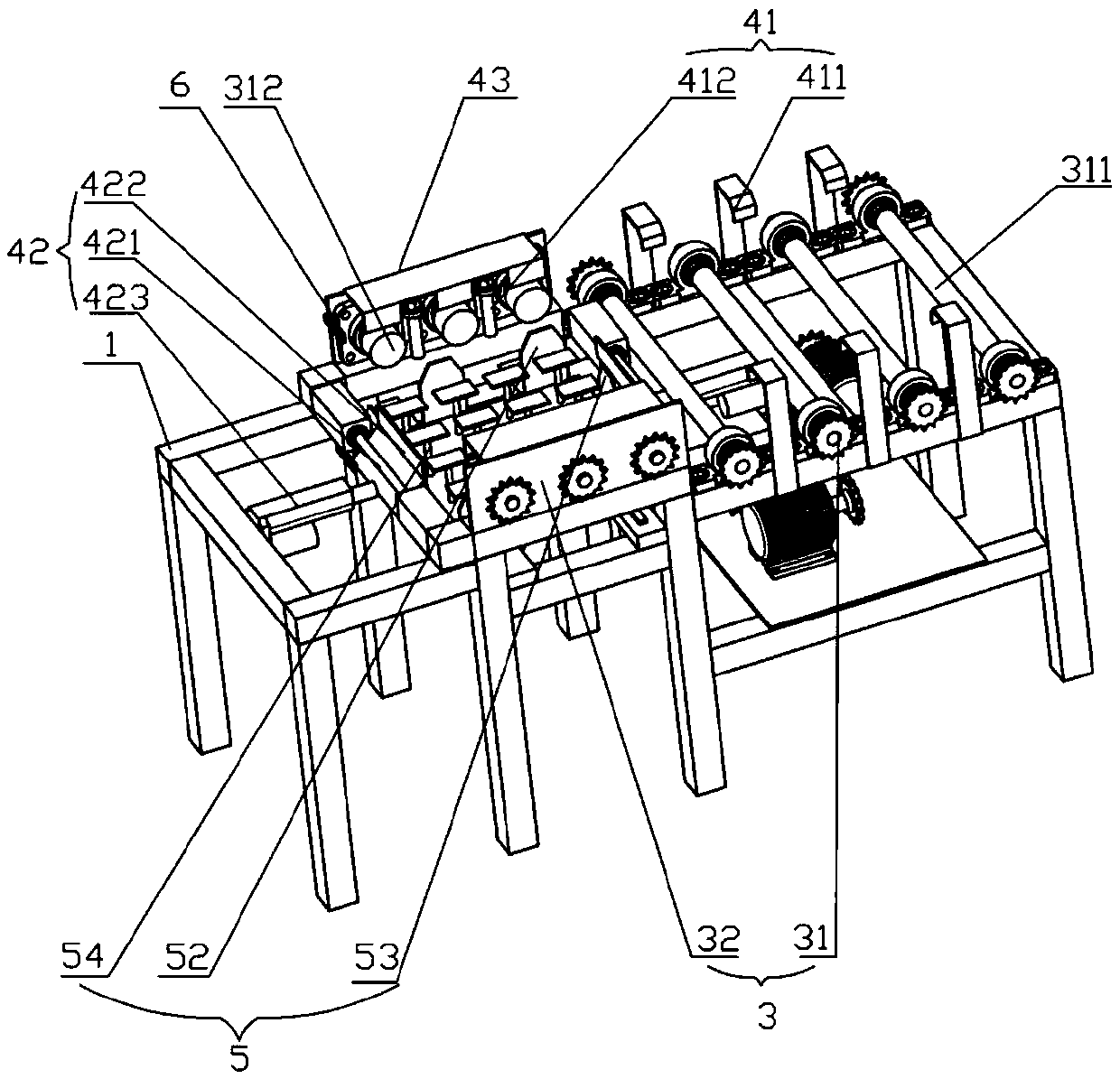

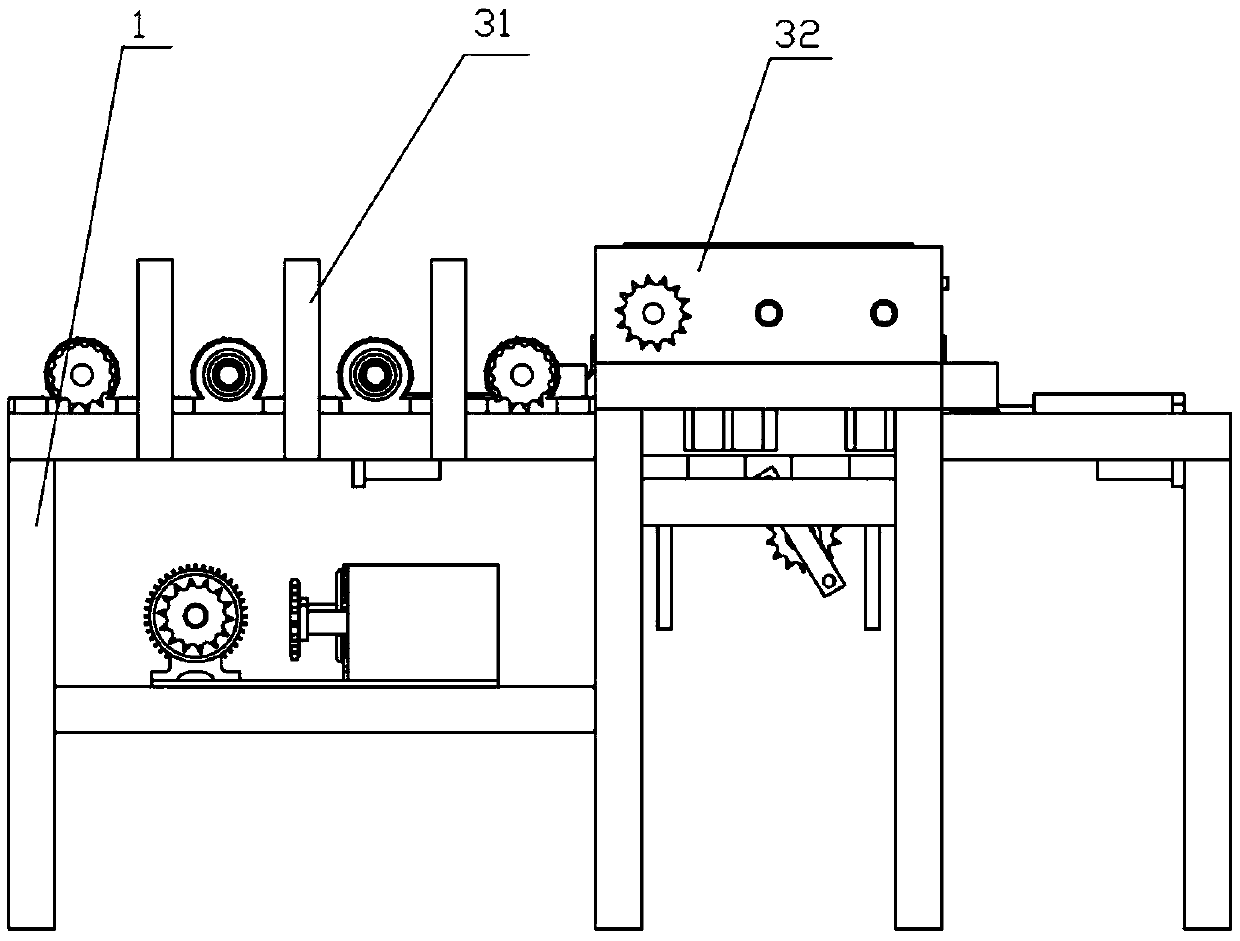

[0033] like Figure 1 to Figure 10 Shown, a kind of pot seedling top seedling system comprises frame 1 and is installed on the frame 1 and is used for conveying device 3 of movable seedling tray 2, is used for the positioning device 4 of positioning and clamping movable seedling tray 2 and is used for The seedling lifting device 5 for removing the pot seedlings from the tray, the conveying device 3 includes a tray conveying mechanism 31 and a top seedling conveying mechanism 32; the positioning device 4 includes a lateral limiting mechanism 41, a longitudinal positioning clamping mechanism 42 and two groups of symmetrical The vertical pressing plate 43 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com