A method for in-situ pre-lithiation of lithium ion battery and lithium ion battery

A lithium-ion battery, in-situ technology, applied in battery electrodes, secondary battery charging/discharging, secondary batteries, etc., can solve the problems of fast capacity decay, low coulomb efficiency, etc., to achieve improved cycle performance, simple process, The effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

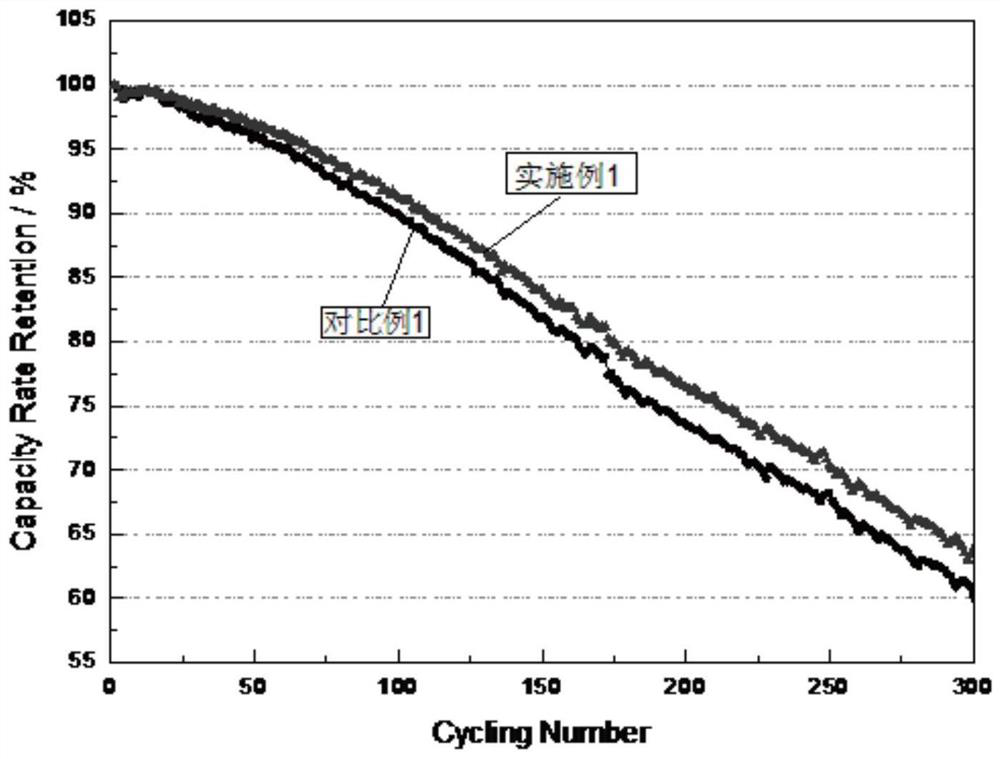

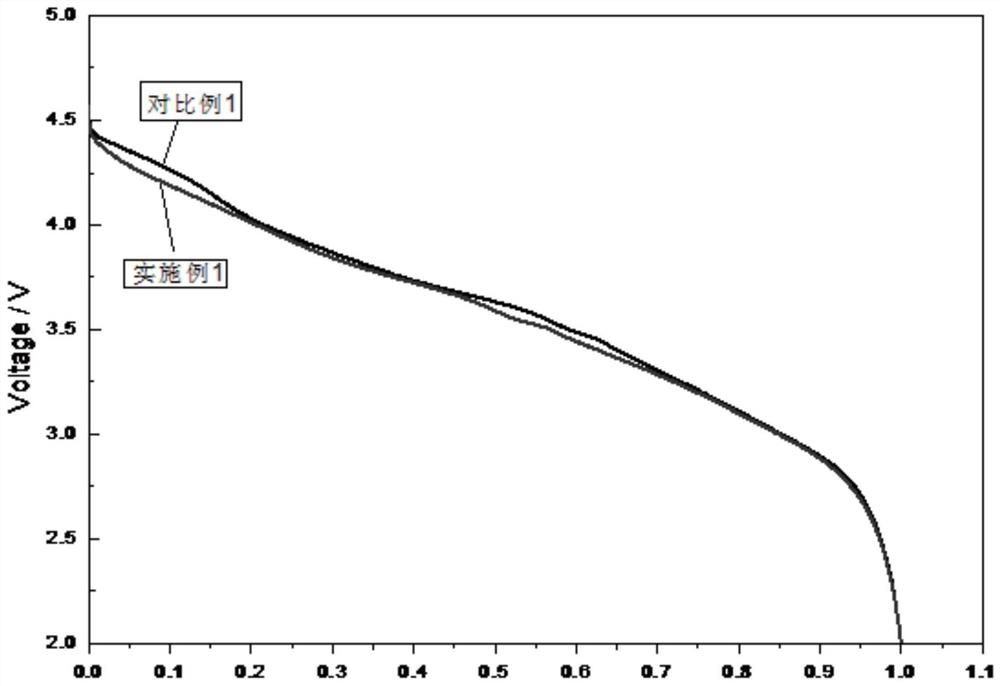

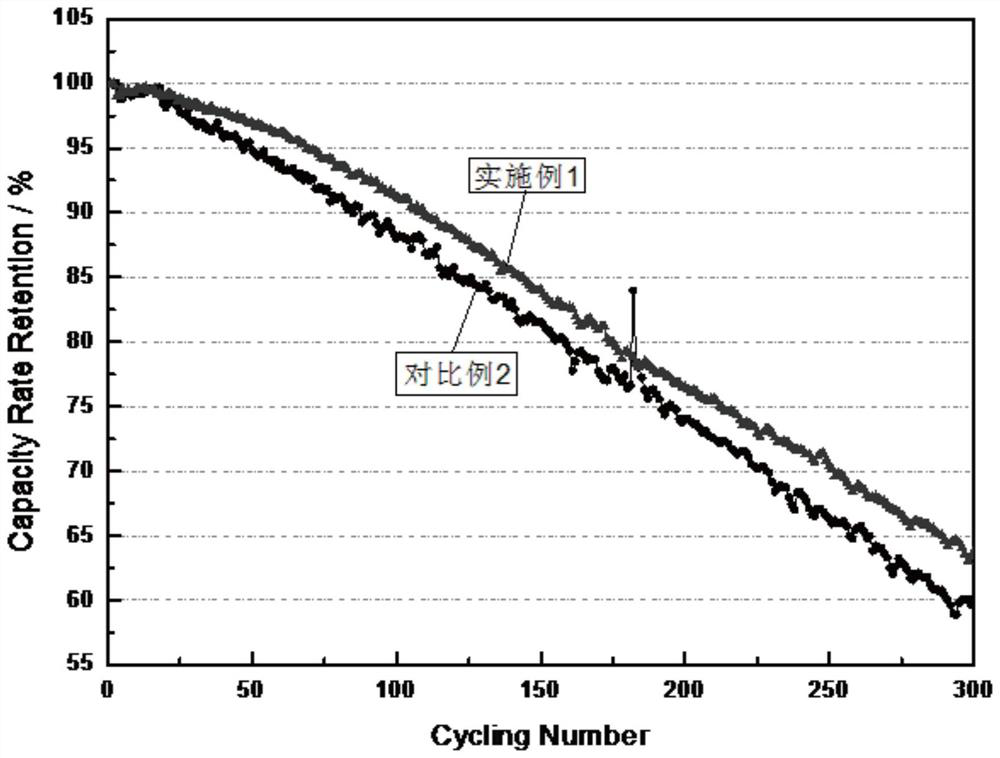

Embodiment 1

[0030] The silicon-carbon composite material with an active silicon content of 15% is used as the negative electrode material, and the lithium-rich manganese-based material is 0.4Li 2 MnO 3 0.6Li(Ni 0.33 co 0.33 mn 0.33 )O 2 As the positive electrode material, N1 / P1=0.90 (N2 / P2 is 1.05) is designed, and a soft-packed lithium-ion battery with a winding structure is prepared.

[0031] Among them, the silicon-carbon composite material with an active silicon content of 15% has a first Coulombic efficiency of 85% and a reversible specific capacity (N2) of 850mAh / g in the voltage range of 5mV to 1.5V; the lithium-rich manganese-based material is 0.4Li 2 MnO 3 0.6Li(Ni 0.33 co 0.33 mn 0.33 )O 2 In the voltage range of 2.0-4.8V, the first Coulombic efficiency is 73%, and the reversible specific capacity (P2) is 230mAh / g.

[0032] The prepared lithium-ion battery is charged to a fully charged state in the first week at a voltage range of 2.0-4.7V and a rate of 0.1C. The desig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com