A fully automatic steel wire rope mechanical performance testing system and testing method

A technology of steel wire rope mechanics and detection system, which is applied in the direction of testing material strength by applying stable torsion force, testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, etc., which can solve the problem of low work efficiency, Large calculation errors, easy to cause accidents and other problems, to save labor costs, reduce measurement errors, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

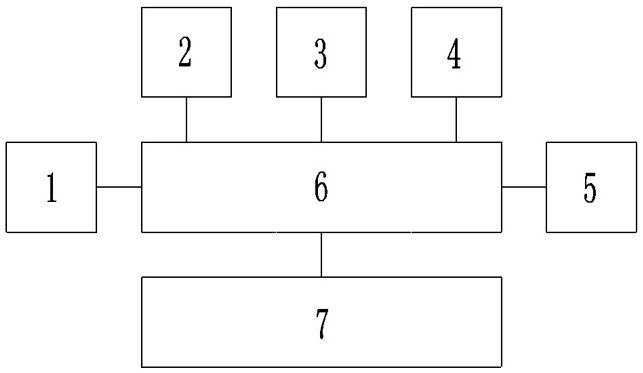

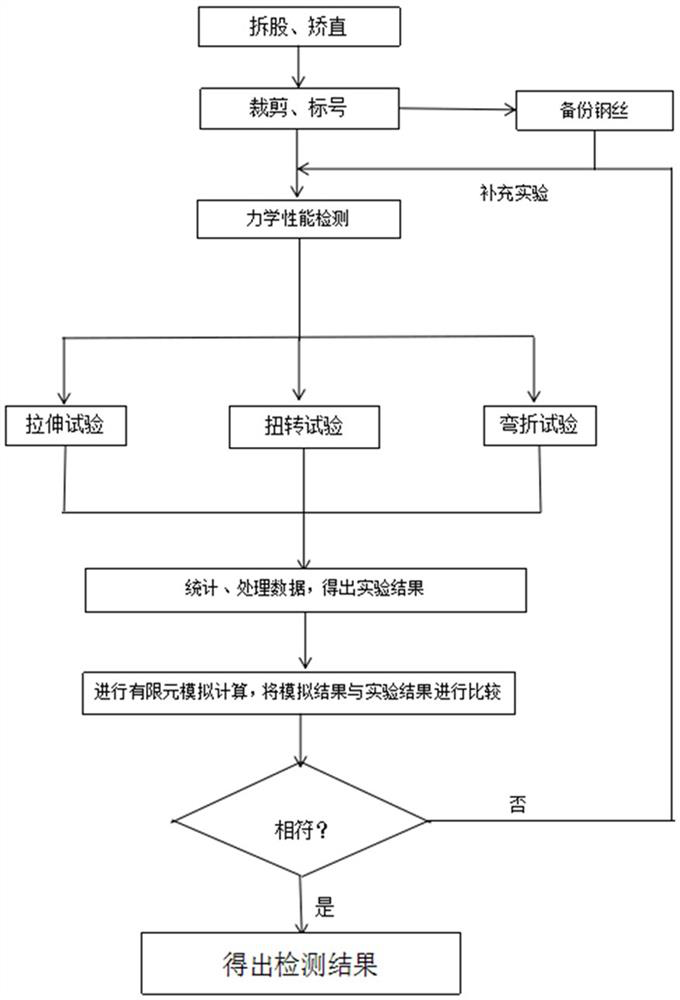

[0053] like Figure 1 to Figure 8 As shown, a fully automatic steel wire rope mechanical performance testing system of the present invention includes a testing machine, the bottom of the testing machine is provided with a base, and the base is provided with a straightening machine 1 and an outlet of the straightening machine 1. A mechanical arm 2 is provided at the feed opening, and the mechanical arm 2 is specifically a rotary mechanical arm with a fixed chassis. A stretching machine 3, a bending machine 4, and a twisting machine 5 are respectively arranged within the active radius of the mechanical arm 2. The control ports of the straightening machine 1, the mechanical arm 2, the stretching machine 3, the bending machine 4, and the twisting machine 5 are all connected to the four-axis controller 6 through wires;

[0054] The four-axis controller 6 is internally integrated with a control circuit, and the AD conversion module provided on the control circuit has 6 signal input ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com