Tooth-groove type waterproof connecting structure adopting pressure-grouting method for horizontal joints of assembling type building prefabricated wall boards

A prefabricated wall panel and connection structure technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problem that the integrity of prefabricated wall panels and laminated floors is not strong, can not effectively prevent rainwater from infiltrating, and cannot ensure the flatness of mortar to improve the phenomenon of water seepage and water accumulation, improve production efficiency and building quality, and optimize the connection structure process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples, but the embodiments of the present invention are not limited thereto, and the scope of protection of the present invention also relates to those skilled in the art who can achieve according to the concept of the present invention. Think of the equivalent technical means.

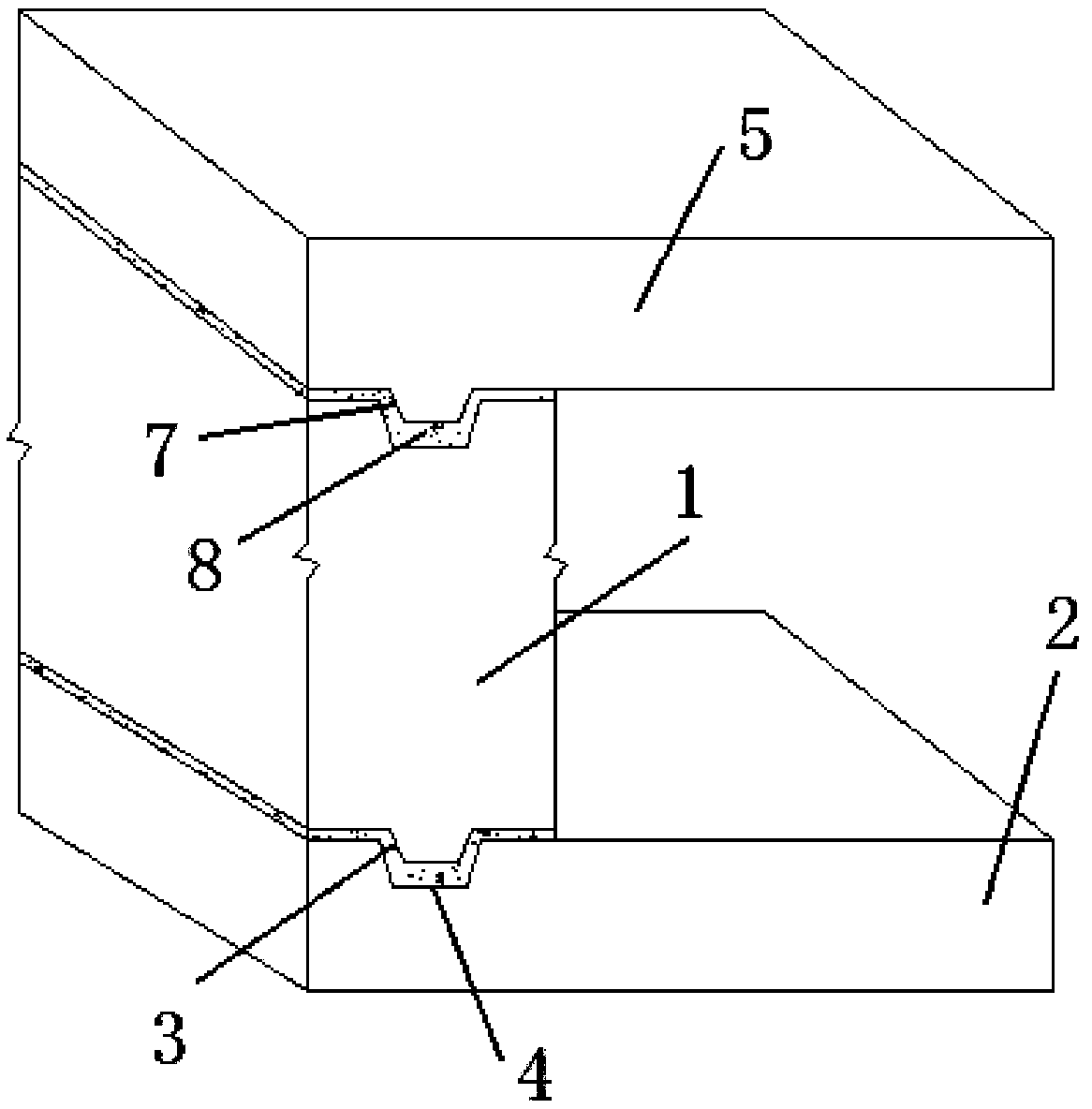

[0017] like figure 1 , 2 As shown, a prefabricated building prefabricated wall panel horizontal joint grouting method alveolar waterproof connection structure, including the prefabricated prefabricated wall panel 1 prefabricated in the prefabricated component factory and the assembly prefabricated wall panel 1 connected The prefabricated floor slab 2 and the prefabricated roof slab 5, the prefabricated floor slab is prefabricated with a lower trapezoidal groove at the position where the prefabricated prefabricated wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com