Automatic slag discharging device for rapid construction of subway and automatic slag discharging method

An automatic and subway technology, applied in the direction of lifting devices, etc., can solve the problems of low construction efficiency, occupying space and human resources, etc., and achieve the effect of reducing labor intensity, saving construction sites, reducing on-site operations and ground coordination personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

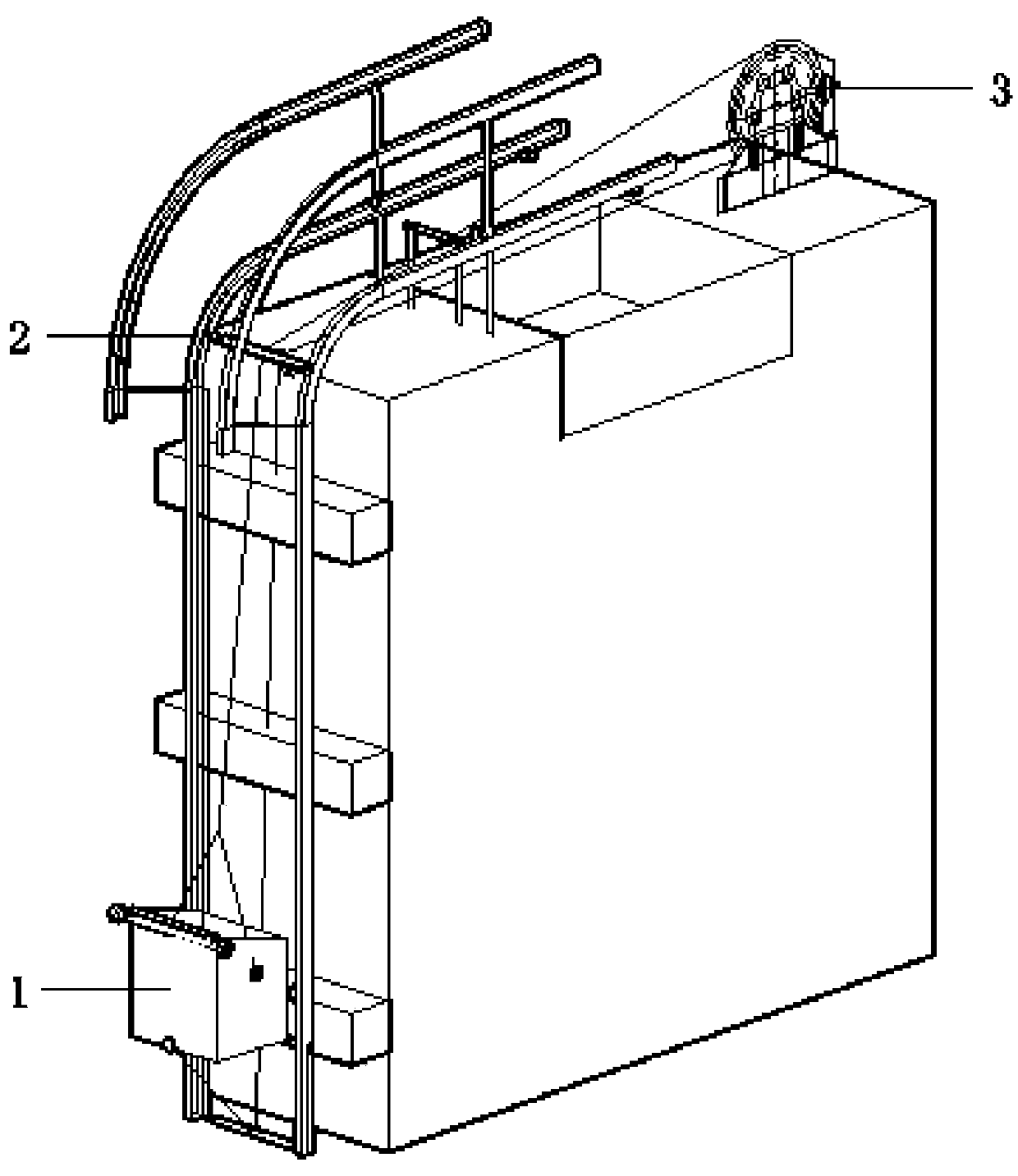

[0039] see figure 1 , an automatic slag discharge device for subway rapid construction, including a slag car 1, used for transporting and dumping slag soil; a traveling mechanism 2, used for walking and position fixing of the slag car; a power system 3, used for the slag car The means and source of power for travel. In the present invention, steel rails are welded on the shaft waist beam as the walking path of the slag truck 1 . Simultaneously, a component interlocking with the openable slag truck floor 12 is provided on the traveling mechanism 2 to realize automatic dumping of the slag soil and automatic reset of the slag truck floor 12 .

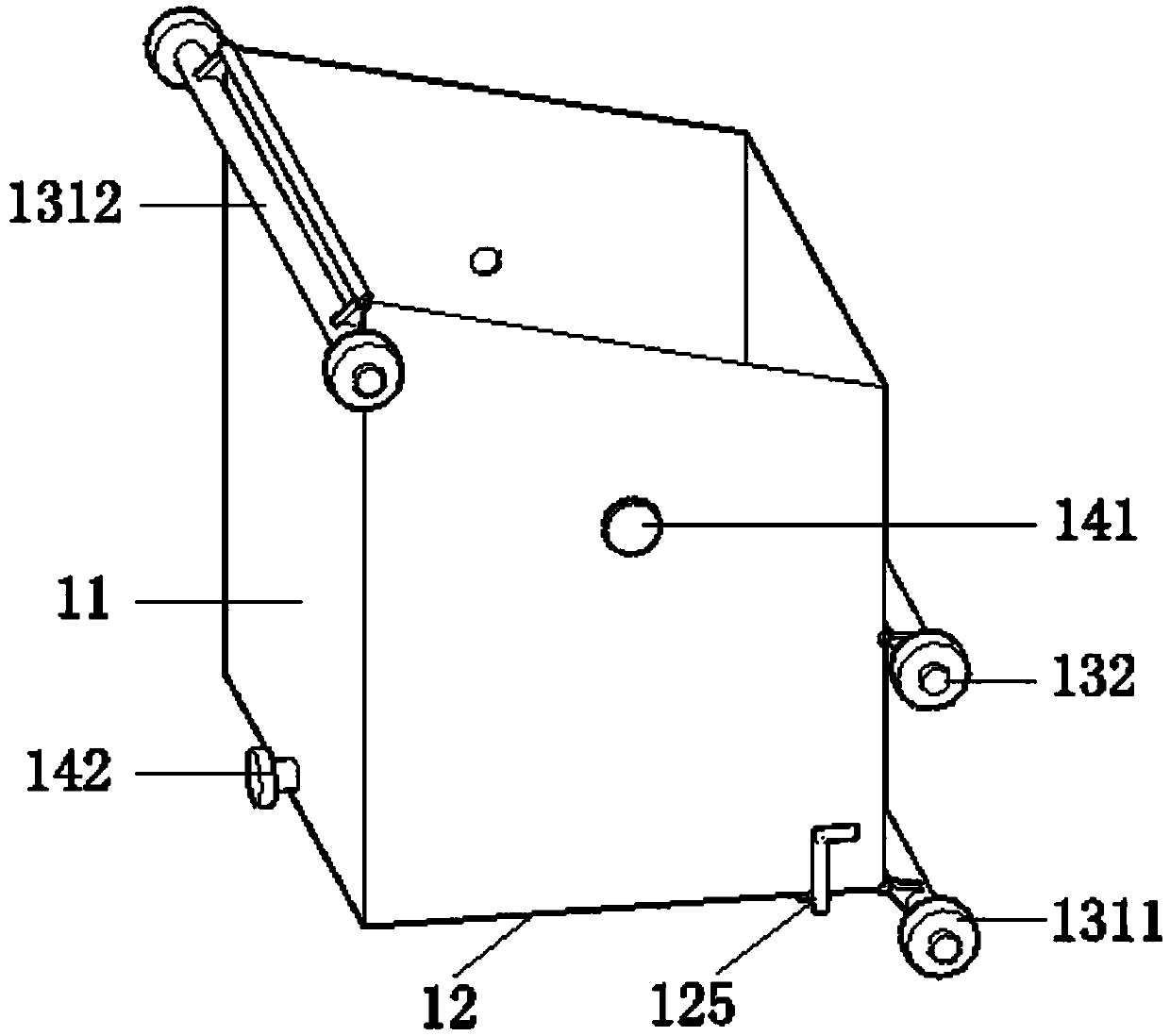

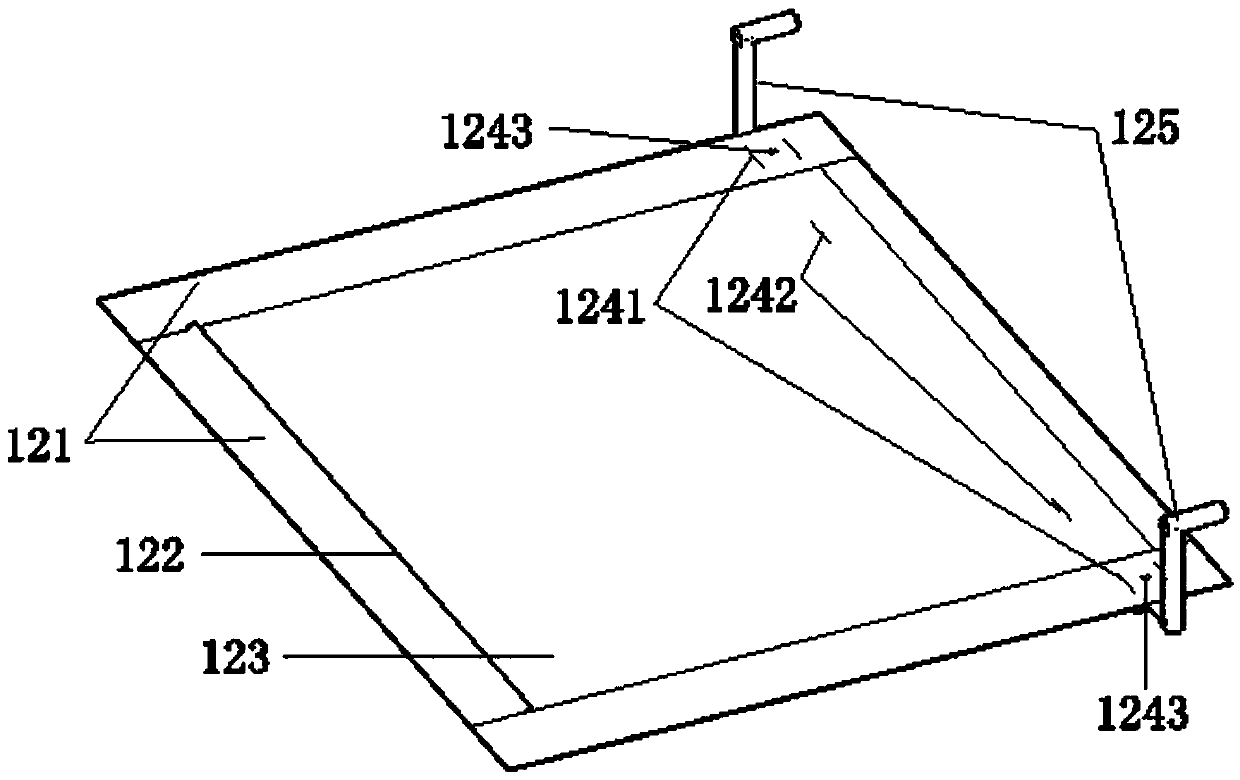

[0040] Such as figure 2 , the slag truck 1 includes a side wall plate 11, a bottom plate 12, wheels 13, and lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com