Blanking mechanical device adopting link type parallel-series structure

A technology of series structure and mechanical device, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as affecting work efficiency and accuracy, increasing arm motion inertia, poor dynamic performance of robots, etc. Accuracy and speed, reducing own weight, avoiding the effects of complex programming of parallel structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

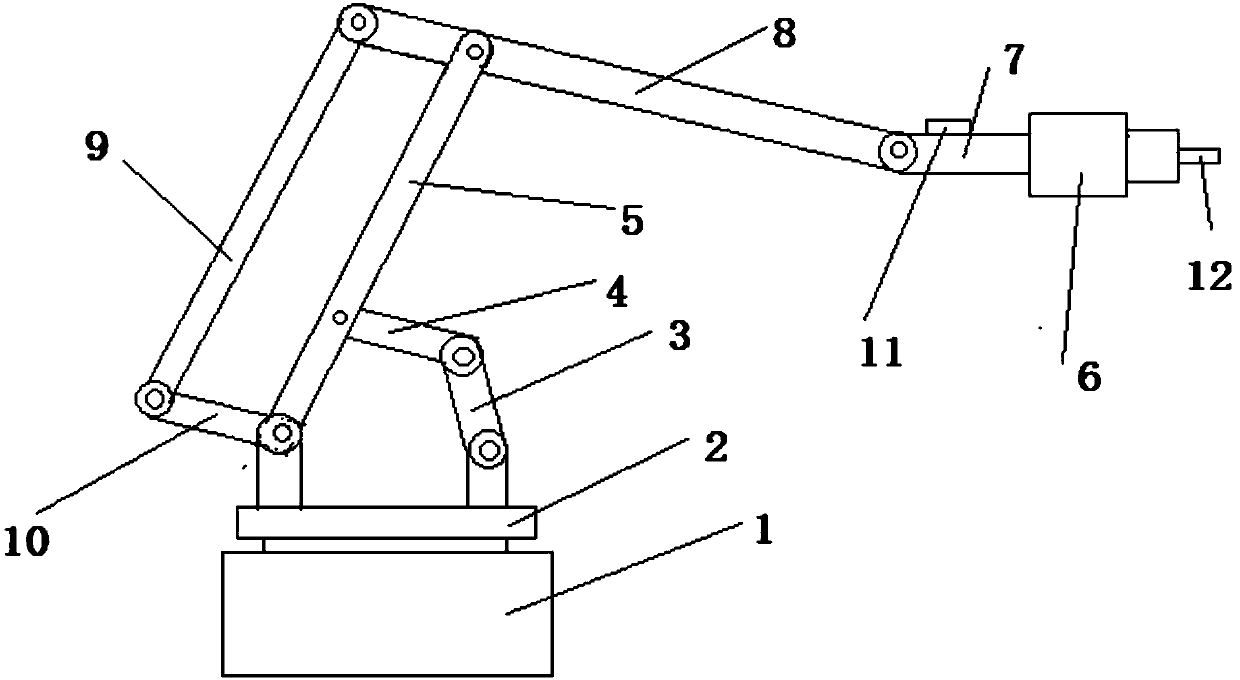

[0007] According to the present invention, a mechanical device for unloading with a rod-type parallel structure structure includes a base 1, a rotary platform 2, a first active rod 3, a second active rod 10, a large arm 5, a large arm connecting rod 4, and a middle arm Connecting rod 9, middle arm 8, forearm 7, wrist 6, torch 12, inclination detector 11 and driving device; One end of the first active rod 3 is connected with the rotary platform 2, and the other end of the first active rod 3 is connected with the large One end of the arm connecting rod 4 is connected, the other end of the boom connecting rod 4 is connected with one end of the boom 5, one end of the second active rod 10 is connected with the rotary platform 2, the other end of the second active rod 10 is connected with the middle arm connecting rod 9, and the middle arm The other end of the connecting rod 9 is connected to one end of the middle arm 8, one end of the boom 5 is connected to the rotary platform 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com