A sitting type mung bean picking, shelling and stripping shuttle crawler

A technology of crawler and thin car, which is applied in the field of mung bean picking machinery, and can solve problems such as easy lumbar muscle strain and difficulty in walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The technical solutions of this patent will be further described in detail below in conjunction with specific implementations. The technical features or connection relationships of the present invention that are not described in detail are all the existing technologies used.

[0038]Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings.

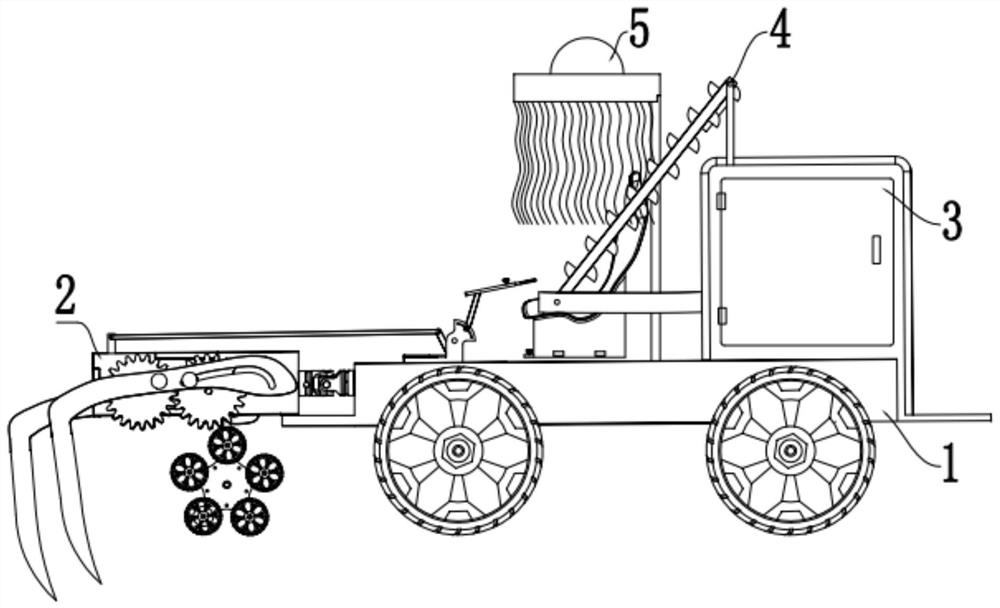

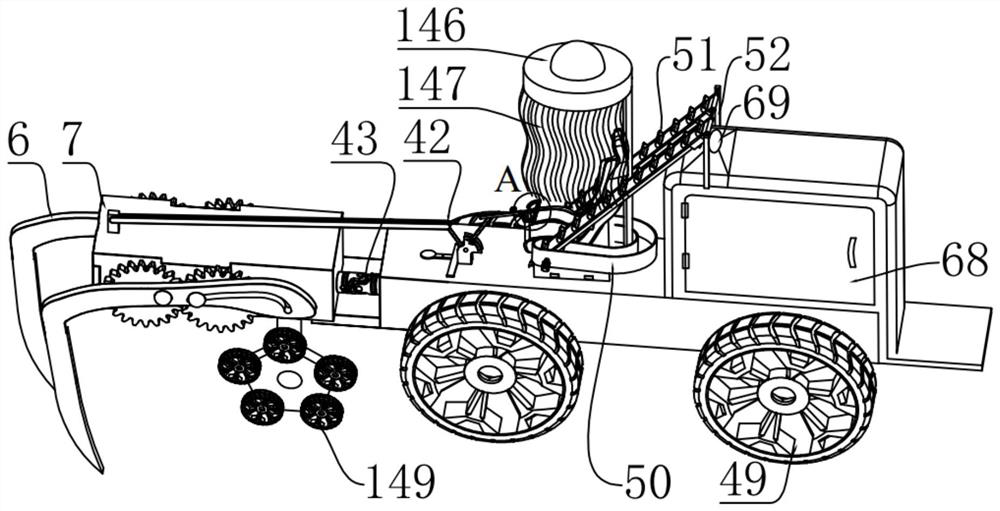

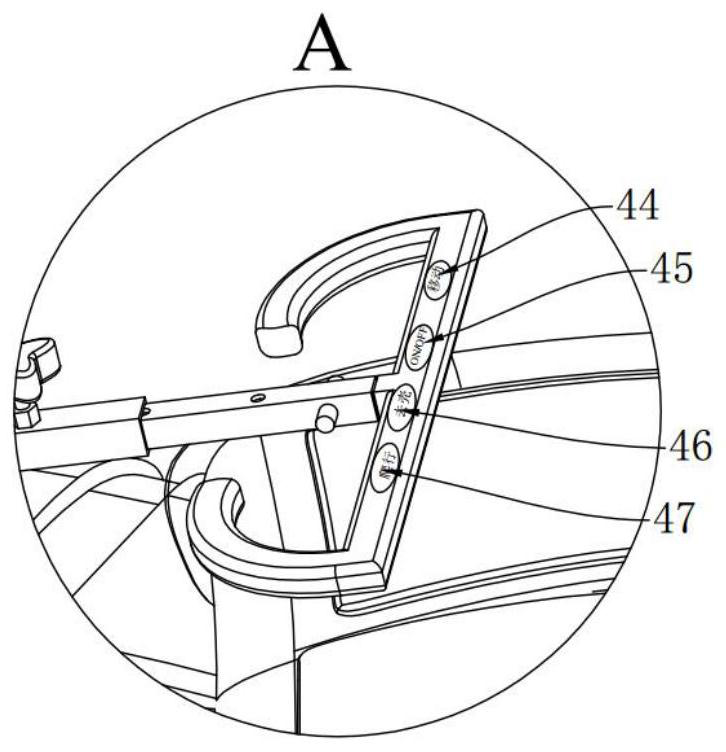

[0039]Such asFigure 1-18As shown, the present invention is a sitting mung bean picking and peeling shredded shuttle crawling vehicle, including a sitting mung bean picking shredder vehicle 1, a crawling moving mechanism 2, a U-shaped oblique conveying mechanism 4 and a multiple non-destructive full peeling device 3. The crawling moving mechanism 2 is arranged in front of the sitting mung bean picking trolley 1, the multiple non-destructive full peeling device 3 is installed on the sitting mung bean picking trolley 1, and the U-shaped oblique conveying mechanism 4 is provided at one end On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com