Method for detecting thermal insulation performance of building reflective thermal insulation coating (flat coating)

A technology of reflective thermal insulation coating and detection method, applied in the field of coatings, can solve problems such as detection data difference, and achieve the effect of simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

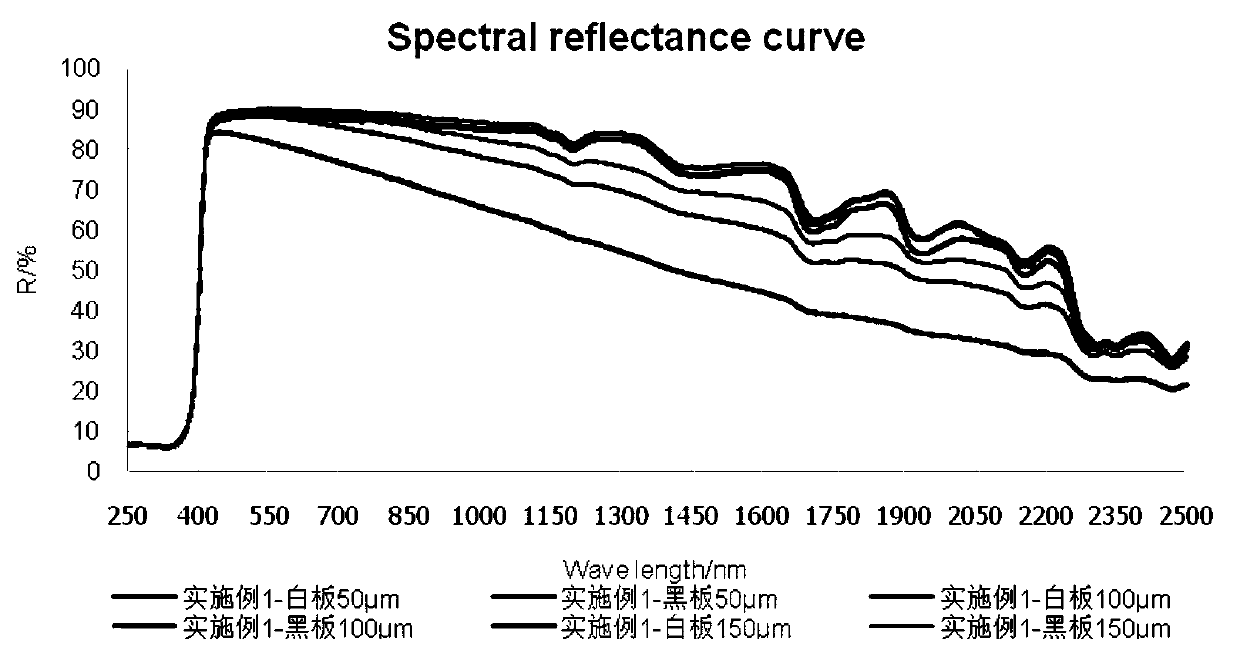

[0025] Example 1 A method for detecting thermal insulation performance of architectural reflective thermal insulation coating (flat coating), including the following steps:

[0026] Step (1): Use a reflectance tester to test the reflectance of the black and white cardboard to ensure that the reflectance of the substrate is within the range of the reflectance of the blackboard <1% and the reflectance of the whiteboard (80±2)%;

[0027] Step (2): The coating is made into a film by using a wire rod coater, and the model of the wire rod coater is RDS65#;

[0028] Step (3): Place the coated film in a constant temperature and humidity room for 7 days to achieve the best test state;

[0029] Step (4): Use a digital micrometer to confirm that the film thickness is 50 microns;

[0030] Step (5): Use an ultraviolet-visible-near-infrared spectrophotometer to test the near-infrared reflectance of the coating;

[0031] Step (6): According to the hiding power calculation formula, calculate the near-in...

Embodiment 2

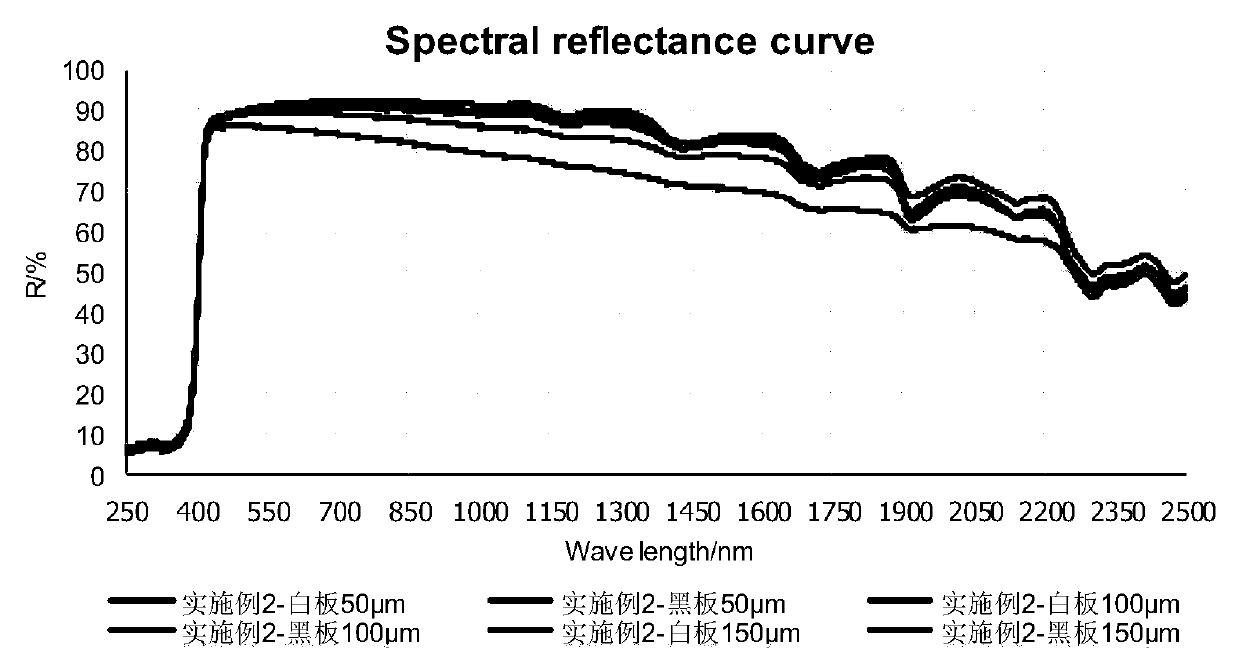

[0032] Embodiment 2 A method for detecting thermal insulation performance of architectural reflective thermal insulation paint (flat coating), including the following steps:

[0033] Step (1): On the basis of the test board of Example 1, use the wire rod coater to make the coating film again, and the model of the wire rod coater is RDS65#;

[0034] Step (2): Place the coated film in a constant temperature and humidity room for 7 days to achieve the best test state;

[0035] Step (3): Use a digital micrometer to confirm that the coating film thickness is 100 microns;

[0036] Step (4): Use an ultraviolet-visible-near-infrared spectrophotometer to test the near-infrared reflectance of the coating;

[0037] Step (5): According to the hiding power calculation formula, calculate the near-infrared hiding power of the coating.

Embodiment 3

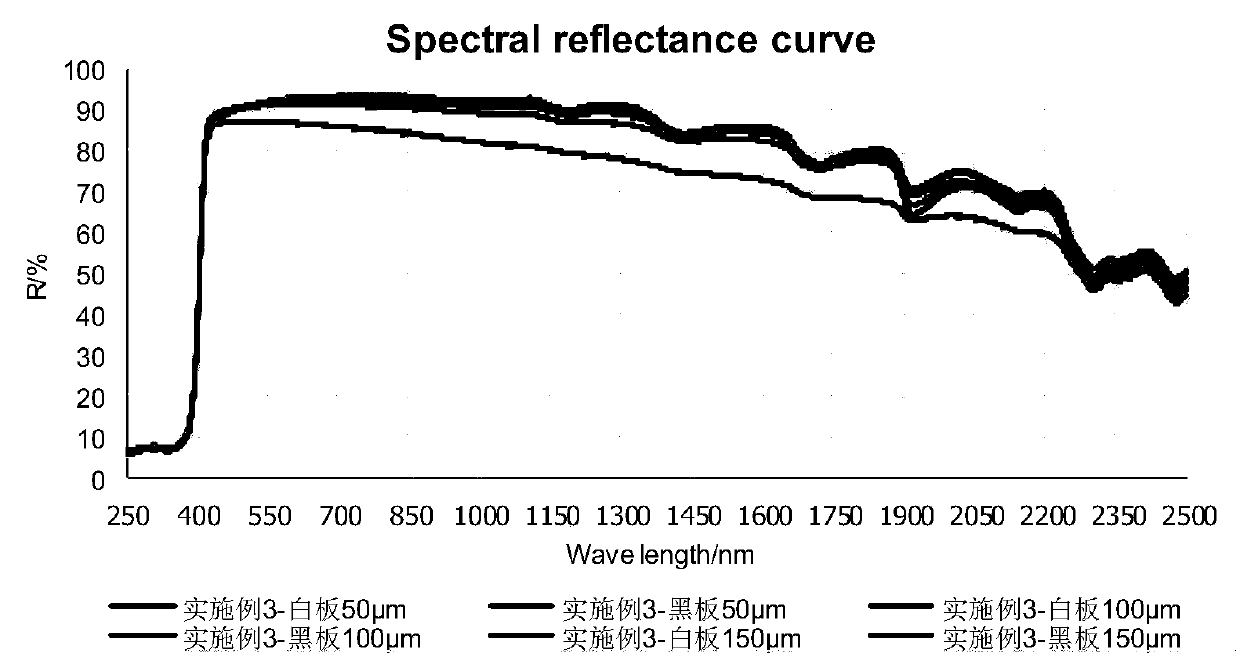

[0038] Embodiment 3 A method for detecting thermal insulation performance of architectural reflective thermal insulation paint (flat coating), including the following steps:

[0039] Step (1): On the basis of the test board of Example 2, use the wire rod coater to make the coating for the third time, and the wire rod coater model is RDS65#;

[0040] Step (2): Place the coated film in a constant temperature and humidity room for 7 days to achieve the best test state;

[0041] Step (3): Use a digital micrometer to confirm that the coating film thickness is 100 microns;

[0042] Step (4): Use an ultraviolet-visible-near-infrared spectrophotometer to test the near-infrared reflectance of the coating;

[0043] Step (5): According to the hiding power calculation formula, calculate the near-infrared hiding power of the coating.

[0044] The specific test results of Examples 1-3 are as follows:

[0045]

[0046] In summary, since the energy in sunlight mainly comes from near infrared, which accou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com