Intelligent ultra-low-temperature liquid unloading device and unloading process

A truck unloading device and ultra-low temperature technology, which is applied in gas/liquid distribution and storage, fluid treatment, pressure vessels, etc., can solve the problems of slow unloading speed, the pressure difference between the tank truck and the storage tank cannot be kept relatively constant, and the failure of the unloading pump. Achieve the effects of reducing emissions, reducing cavitation and failure rates, and shortening unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

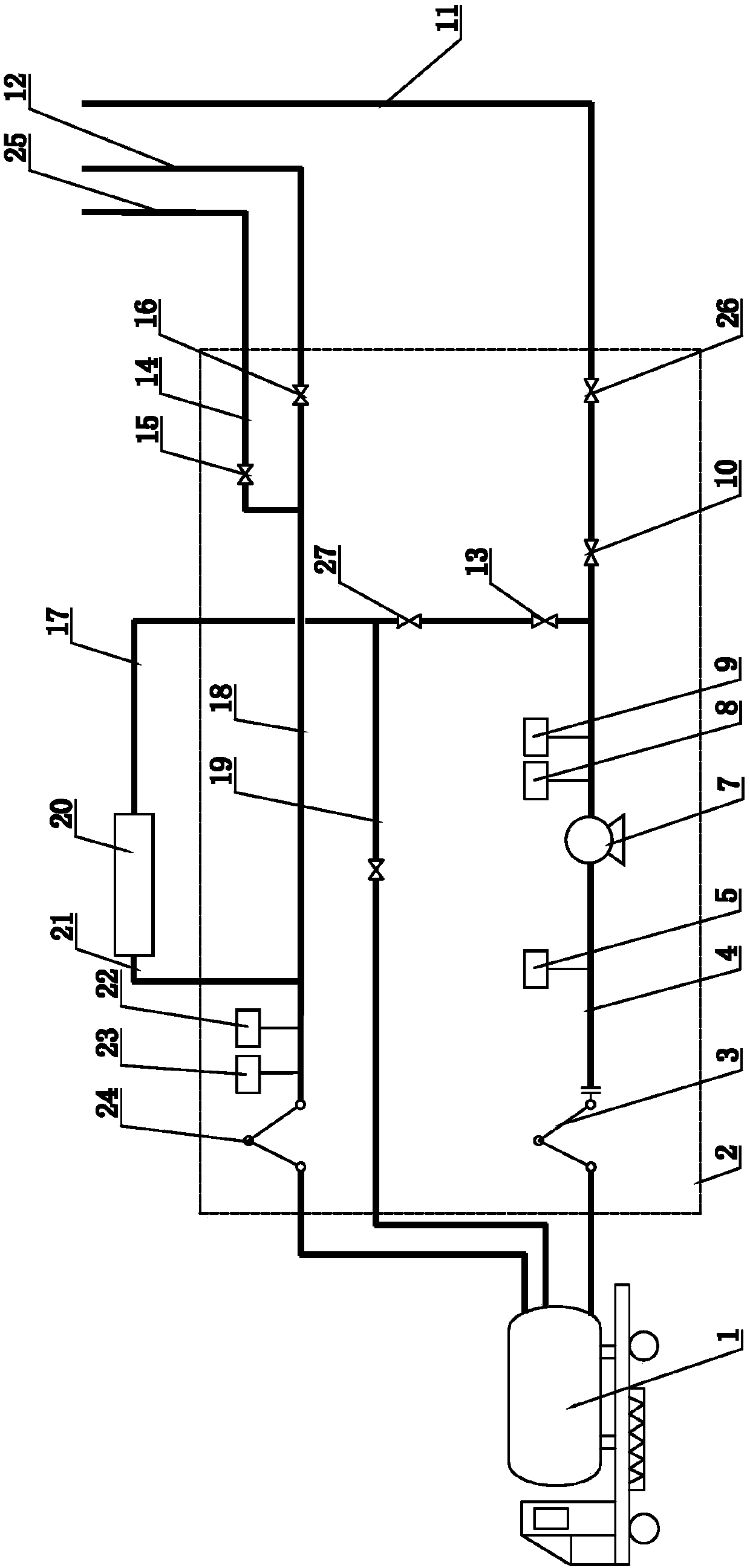

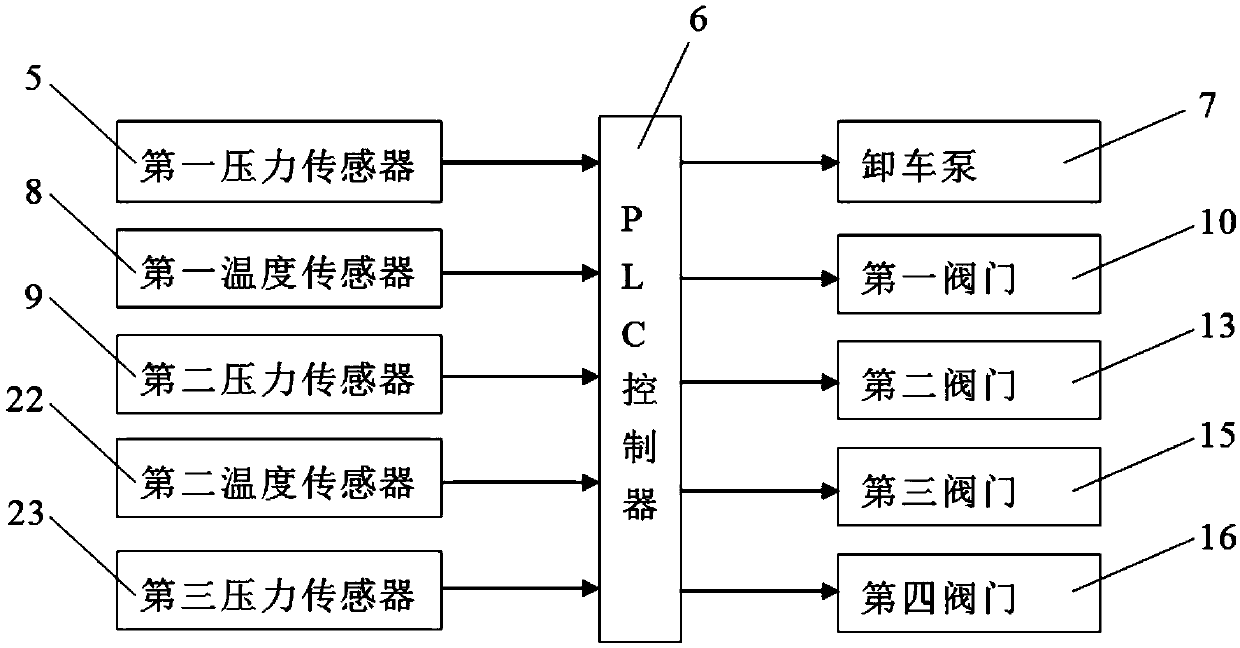

[0067] Such as figure 1 As shown, the intelligent ultra-low temperature liquid unloading device of the present invention includes a tank car 1, a cryopump skid 2 and a booster vaporizer 20, and the tank car is provided with a tank car liquid phase interface, a tank car gas phase interface and a pressurized liquid Phase interface, the cryopump skid 2 includes the liquid phase arm 3 of the unloading crane tube, the unloading pipeline 4, the gas phase arm 24 of the unloading crane tube and the gas phase pipeline 18, and the liquid phase interface of the tank truck passes through the liquid phase arm 3 of the unloading crane tube It is connected to one end of the unloading pipeline 4, and the other end of the unloading pipeline 4 is connected to the liquid phase main pipe 11 of the storage tank. The tank car gas phase interface is connected to one end of the gas phase pipeline 18 through the gas phase arm 24 of the unloading crane pipe. The other end of 18 is connected to the gas ...

Embodiment 2

[0074] When the storage tank is an atmospheric storage tank, that is, when the pressure P in the storage tank is 0.1MPa, the process of using the device of the present invention to unload the ultra-low temperature liquid includes:

[0075] Step 1, nitrogen replacement is carried out to the air in each pipeline of the device;

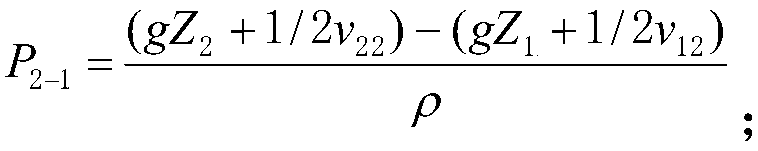

[0076] Step 2: The ultra-low temperature liquid in the tank car 1 enters the liquid phase branch 17 through the unloading pipeline 4 and the first pipeline 19, and then is introduced into the booster gasifier 20 to pressurize the tank car 1. The opening and closing degree of the second valve 13 on the liquid phase branch 17 controls the flow rate of the ultra-low temperature liquid entering the supercharged vaporizer 20, and the pressure in the tank car 1 continues to rise. When the first pressure sensor 5 detects that the tank car 1 internal pressure P 1 When it reaches 0.4MPa~0.8MPa and the dynamic quantity ΔP satisfies the following conditions, the f...

Embodiment 3

[0112] When the storage tank is a pressurized storage tank, that is, when the pressure in the storage tank is 0.4MPa~1.0MPa, the process of using the device of the present invention to unload ultra-low temperature liquid includes:

[0113] Step 1, nitrogen replacement is carried out to the air in each pipeline of the device;

[0114] Step 2: first judge the pressure difference between the storage tank and the tank car 1, when the pressure P in the storage tank is greater than the pressure P in the tank car 1 detected by the first pressure sensor 5 1 , open the fourth valve 16, balance the pressure of the tank car 1 and the storage tank through the gas phase pipeline 18, and close the fourth valve 16 after the pressure is balanced; the ultra-low temperature liquid in the tank car 1 passes through the unloading pipeline 4 and the first pipe The road 19 enters the liquid phase branch 17, and then introduces into the booster gasifier 20 to pressurize the tank car 1. During the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com