A control method of RGV based on a single liter platform

A platform and pallet technology, applied in the RGV field, can solve problems affecting logistics safety, pallet material falling, pallet material overturning, etc., to achieve high safety, high reliability, and automatic access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

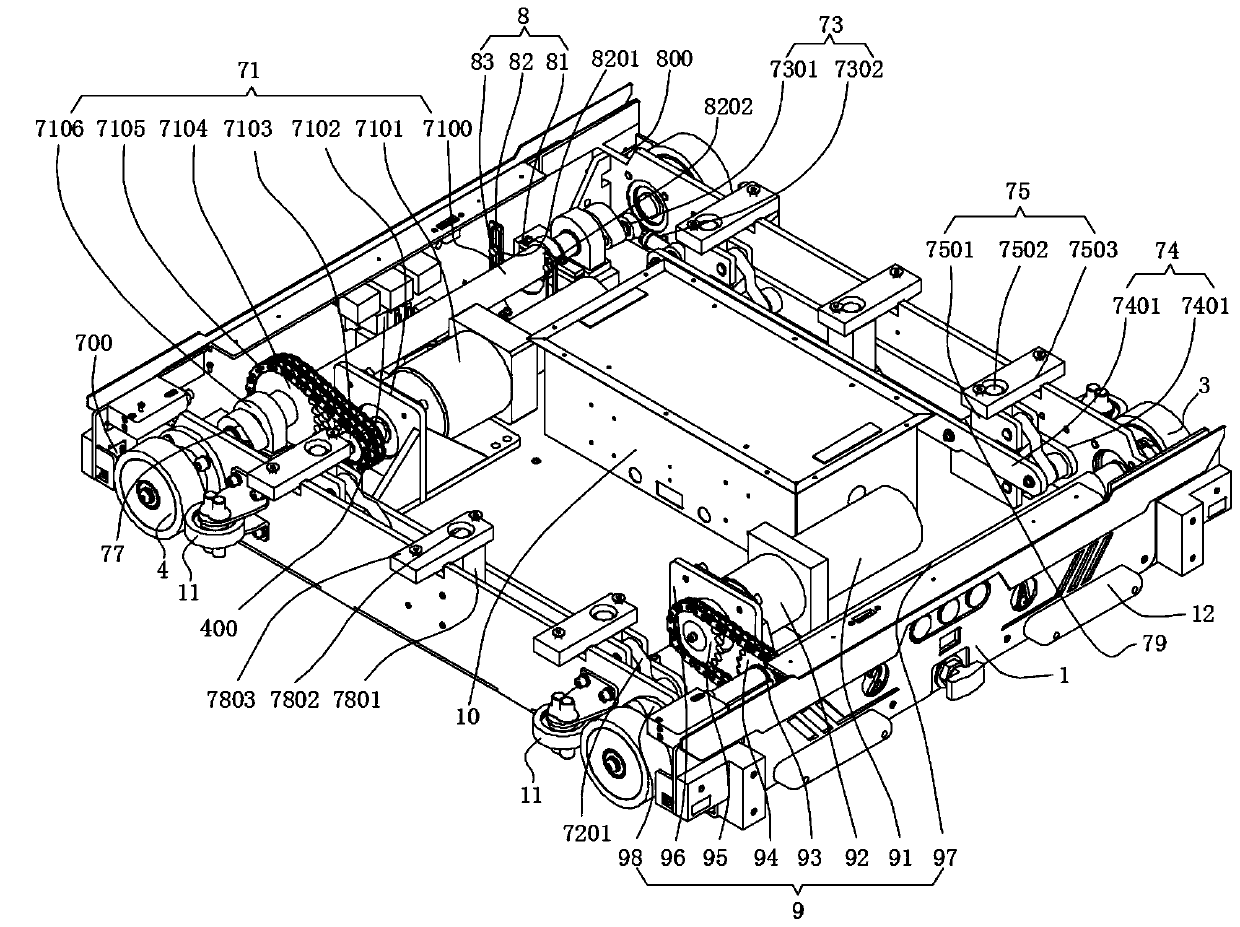

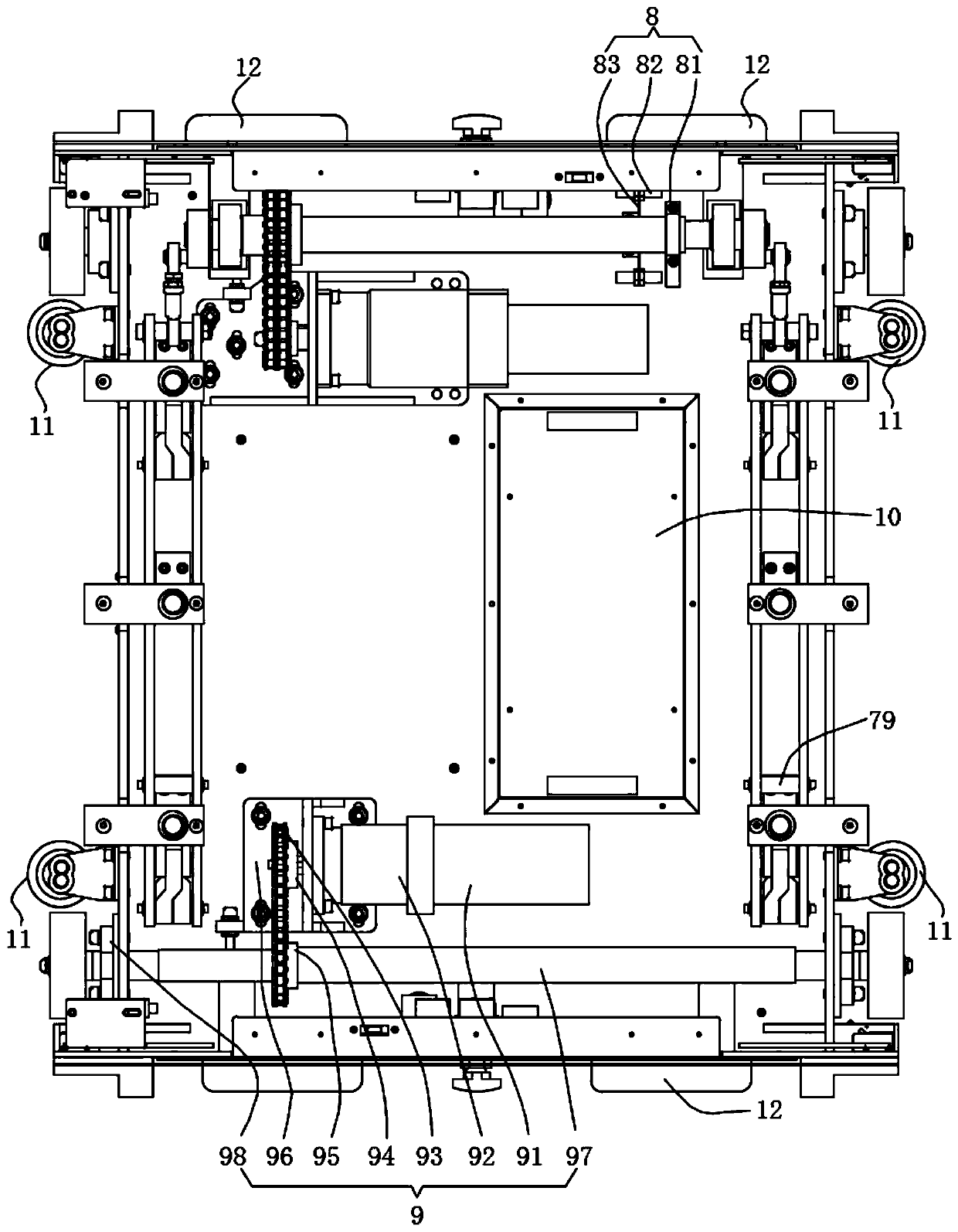

[0031] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

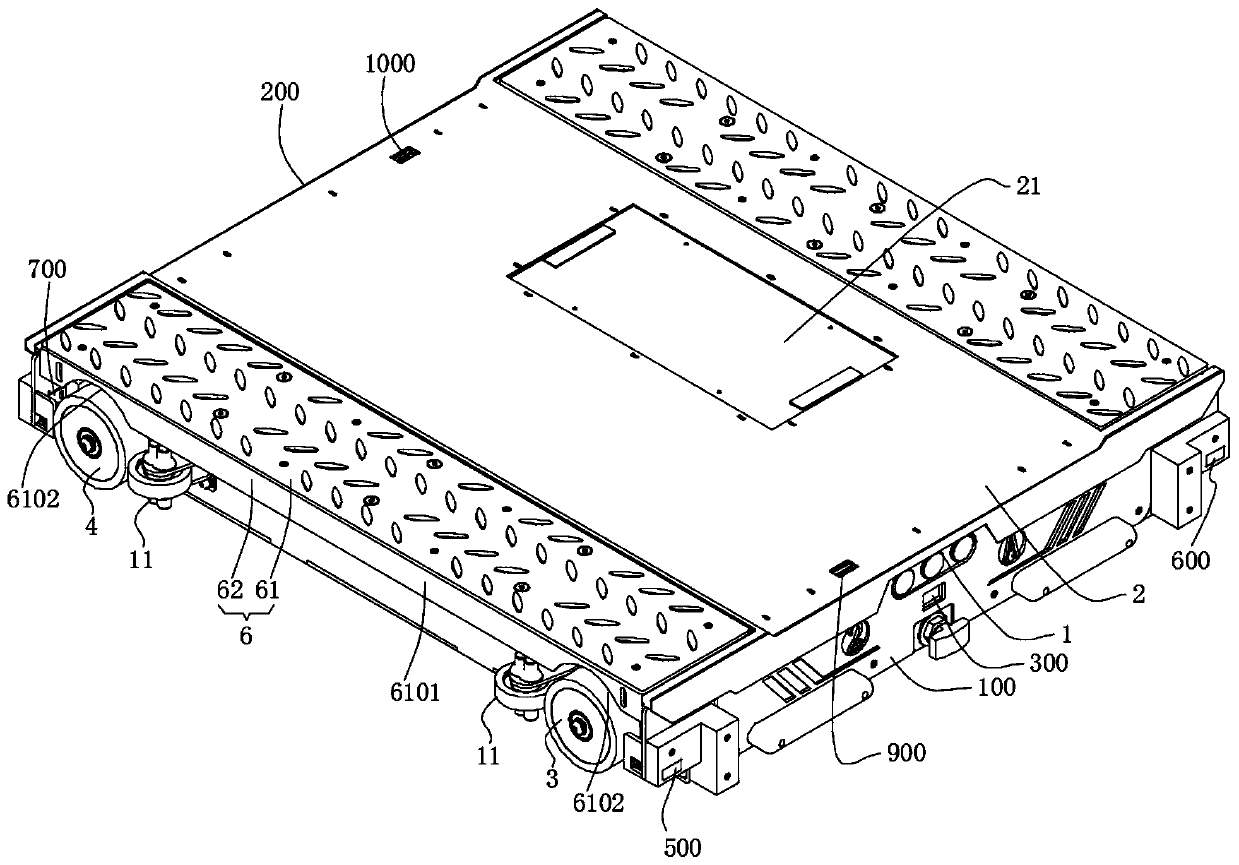

[0032] Such as Figure 1-8 As shown, an RGV based on a single-lift platform consists of a car body 1, a car body cover 2, a driving wheel 3 and a driven wheel 4 arranged on both sides of the car body, a single-lift platform 5 and a drive set inside the car body 1. The single-lift platform 5 is provided with a sensing device 8 for sensing the lifting position, the driving mechanism 6 drives the driving wheels 3, and the vehicle body cover 2 is on the vehicle body 1.

[0033] Such as figure 1 with figure 2 As shown, the car body 1 is provided with a car body cover 2 and a battery box assembly 10, the car body cover 2 has a battery box assembly installation port 21; the battery box assembly provides power for the RGV; the car body cover is provided with a battery box installation port 21 It is convenient to remove and install the battery box group 21.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com