Diffusion device for discharging waste water from ship tail gas desulfurization system

A diffusion device and desulfurization system technology, applied in water treatment devices, ship parts, ship construction, etc., can solve the problems of increased diffusion effect and system resistance, so as to reduce drainage resistance, effectively diffuse waste water, and reduce drainage obstruction interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

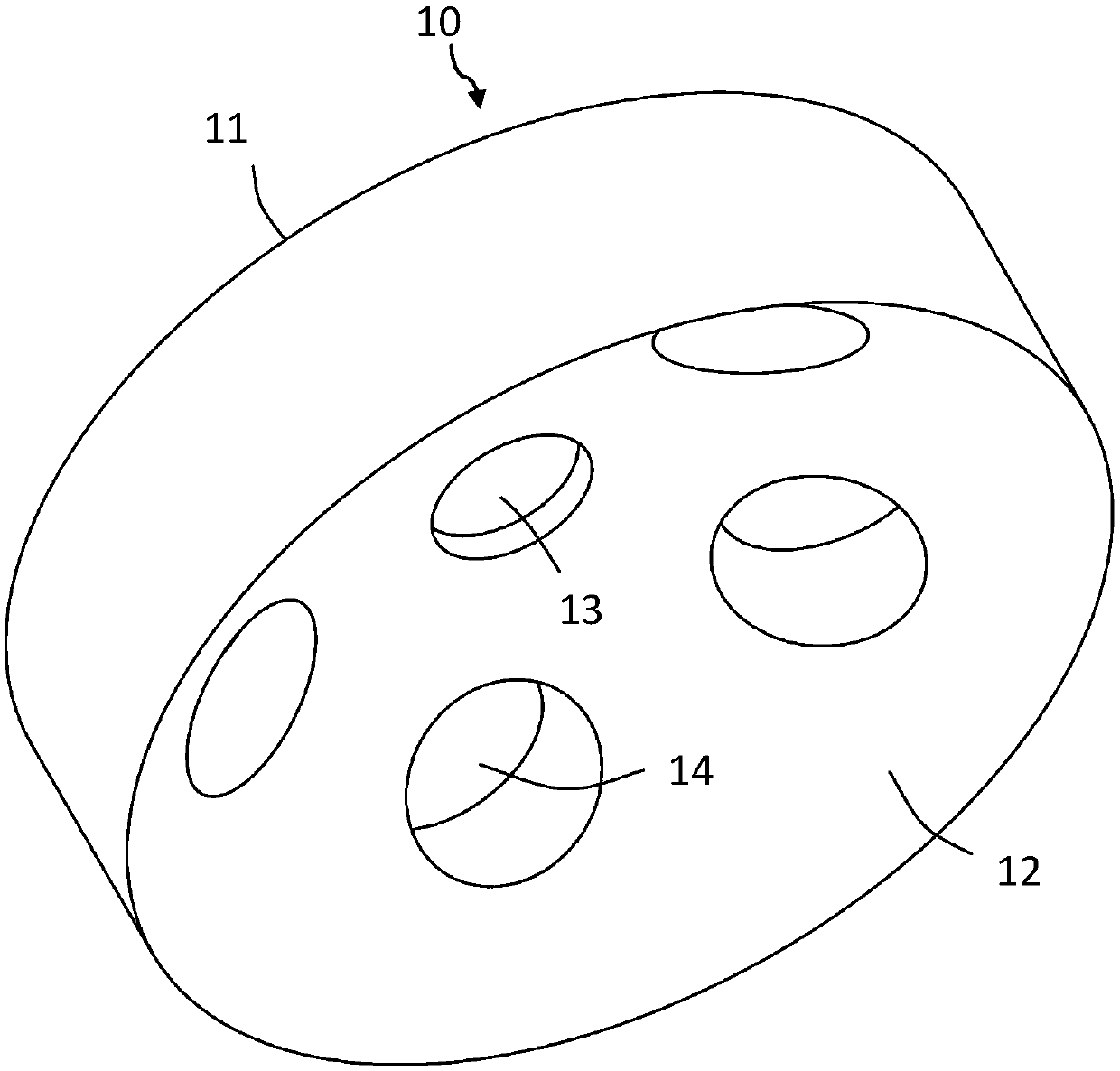

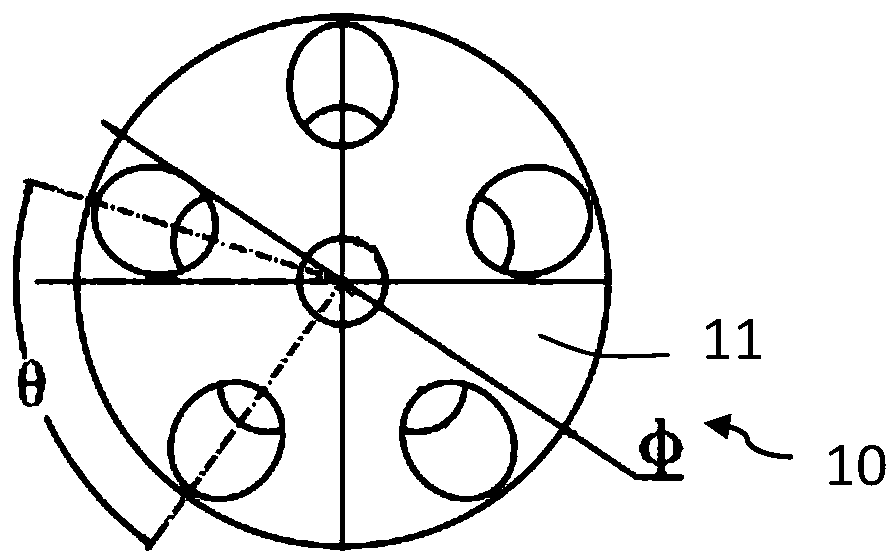

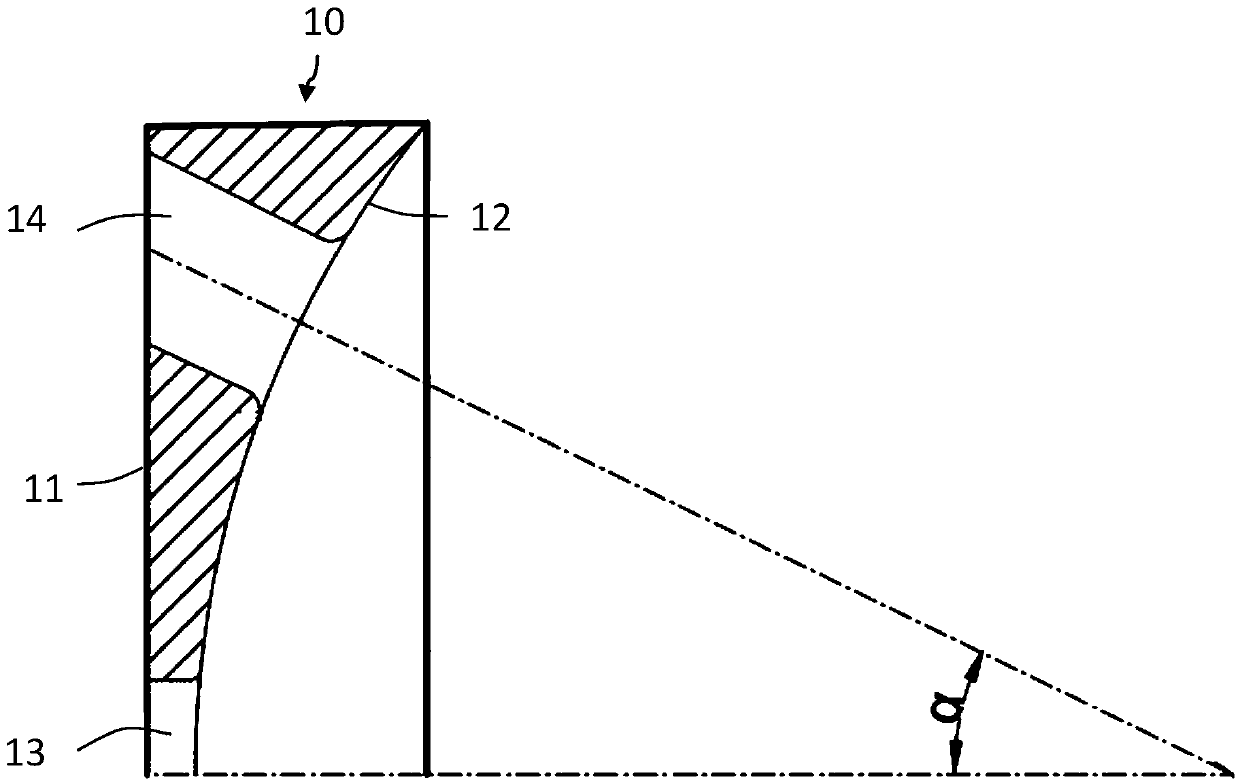

[0056] The inner diameter of the drainage pipe is 400mm, and the drainage flow is 600m 3 / h, the pH value of the drainage is 2.6. Diffuse the drain dilution using the following diffuser. The diameter of the diffusion device is 400mm, the radius of the inner arc of the concave surface 12 is 280mm, one central diffusion hole with a diameter of 40mm; six peripheral diffusion holes with a diameter of 60mm respectively, the elevation angle а of the holes is 28°, and the angle θ between the holes is 60° ; The central thickness of the cylindrical body is 12mm respectively. The rounding radius of the inner side of each round hole is 8mm. Under this structure, the pH value of the drainage can reach 6.7 at a distance of 4 meters from the outlet from the outlet of 2.6. The resistance level of the structural system is 32kpa, and the setting of the diffusion device significantly improves the dilution effect of the washing wastewater discharge, making the washing wastewater easily meet t...

Embodiment 2

[0058] The inner diameter of the drainage pipe is 300mm, and the drainage flow is 680m 3 / h, the pH value of the drainage is 2.6. Diffuse the drain dilution using the following diffuser. The diameter of the diffuser is 300mm, the inner arc radius of the concave surface 12 is 240mm, and 6 drainage holes are arranged on the arc surface. There is 1 central diffusion hole with a diameter of 50mm; 5 peripheral diffusion holes with a diameter of 70mm each, the hole elevation angle а is 30°, and the angle θ between holes is 72°; the central thickness of the cylindrical body is 10mm. The fillet radius of the inner side of each round hole is 6mm. Under this structure, the pH value of the drainage can reach 6.6 at a distance of 4 meters from the water outlet from 2.6 to the water outlet, and the resistance of the diffuser will be 40kpa in this structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com