Fully-automatically recycling ecological breeding system

A cyclic recycling and ecological breeding technology, applied in animal houses, animal feeding devices, organic fertilizers, etc., can solve the problems of increasing transportation and other production facilities, wasting human, financial and material resources, and wasting water resources, saving land. The effect of resources and water resources and human, financial and material resources, avoiding pollution, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

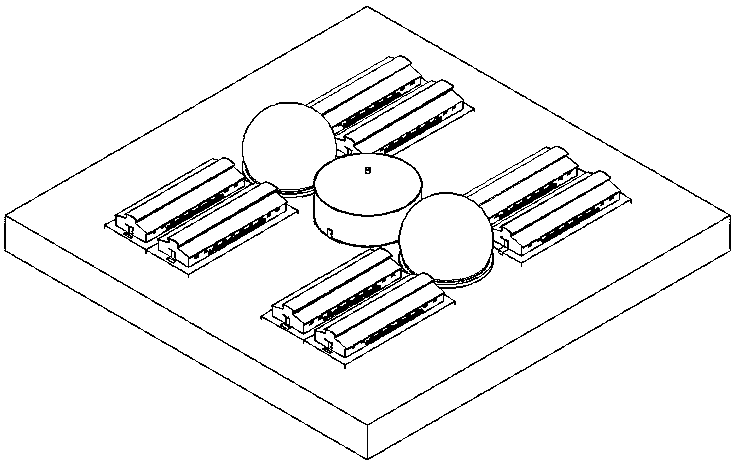

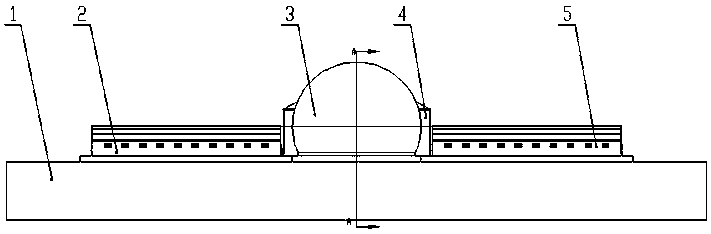

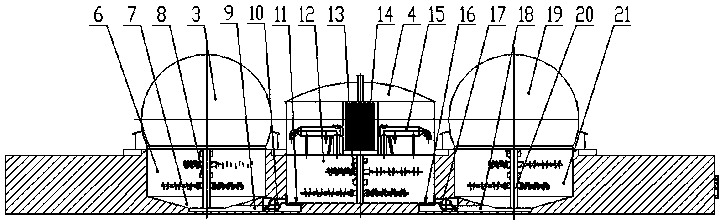

[0016] In order to better understand and implement, the present invention will be further described with the accompanying drawings: the fully automatic recycling ecological breeding system, including automatic feeding system, manure recycling system, biogas fermentation system, organic fertilizer fermentation system and finished product production system, automatic The feeding system includes an automatic feeding device 24 arranged in the livestock house. The automatic feeding device 24 is located above the movable bed body 25 of the livestock house. The movable bed body 25 of the livestock house is arranged above the excrement recycling ditch 26.

[0017] The excrement recycling system includes a excrement recycling trench 26 located below the automatic feeding system. The excrement recycling trench 26 is equipped with an overall excrement recycling device 28. Above the excrement recycling device 28, there are multiple floor drains 27 for overall excrement recycling. The recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com