Power hop anticipation and mitigation

A signal and threshold technology, applied in transportation and packaging, external condition input parameters, control devices, etc., can solve problems such as component wear or failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

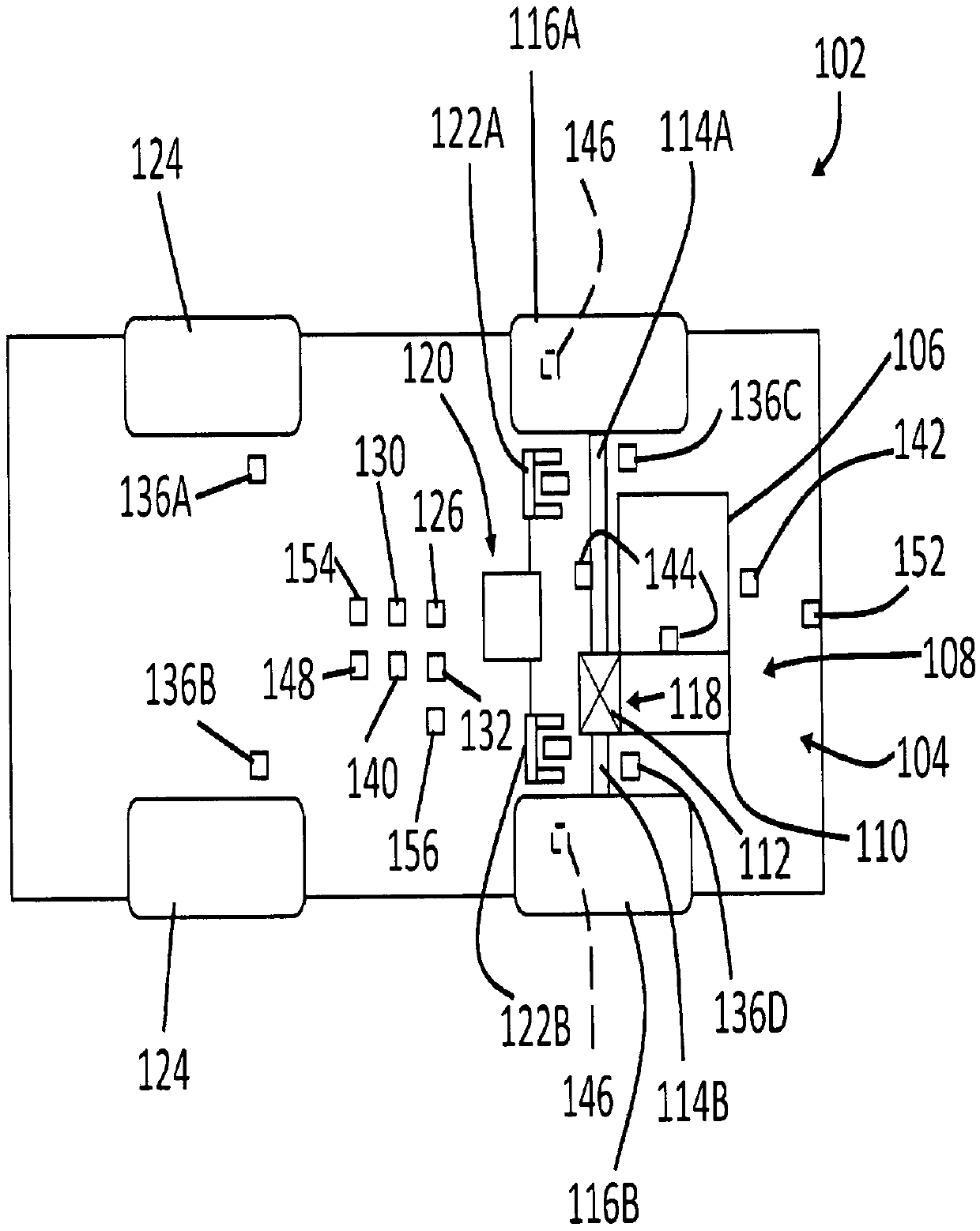

[0015] Reference now Figure 1 to Figure 5 , A control method 100 for predicting and reducing the resonance of a vehicle (usually indicated by 102) is shown. Vehicle 102 in figure 1 It is shown schematically and has a powertrain, usually indicated by 104. The powertrain 104 has a power source 106, such as an internal combustion engine, an electric motor, or other power generating devices for generating torque of the engine or the electric motor.

[0016] The powertrain 104 also has a power transmission system generally indicated by 108, which is connected to the power source 106 and receives engine torque. In the illustrated embodiment, the powertrain 108 is configured as a variable speed differential that includes a transmission 110 and a differential 112. The powertrain 108 is shown in the context of a front-wheel drive (FWD) powertrain, but other powertrain configurations are considered to be within the scope of the present invention. For example, the power transmission sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com