Liquid-cooled cylindrical cell battery module

A battery module, battery module technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of increased weight, more copper sheets, and increased difficulty, reducing the number of parts and compact structure of the module , the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

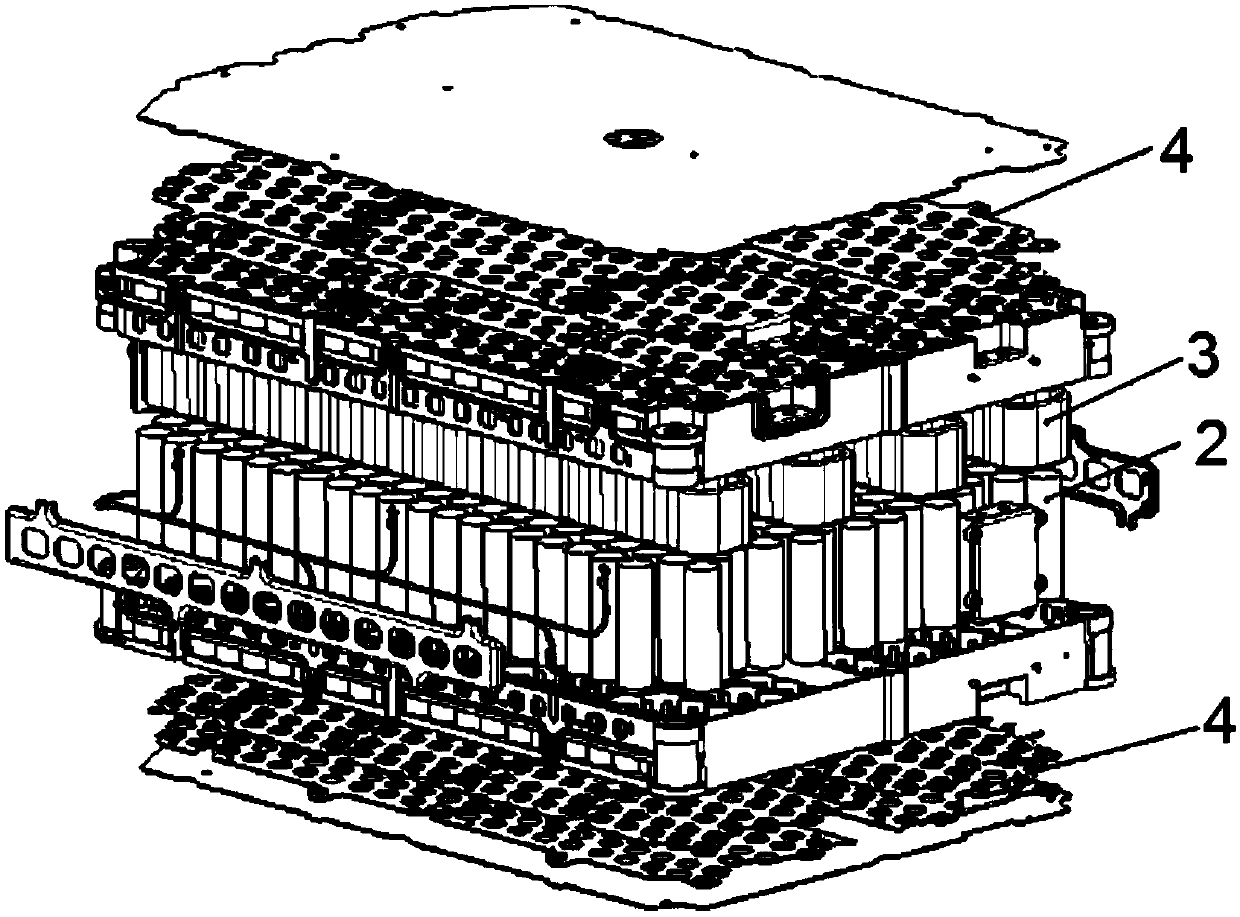

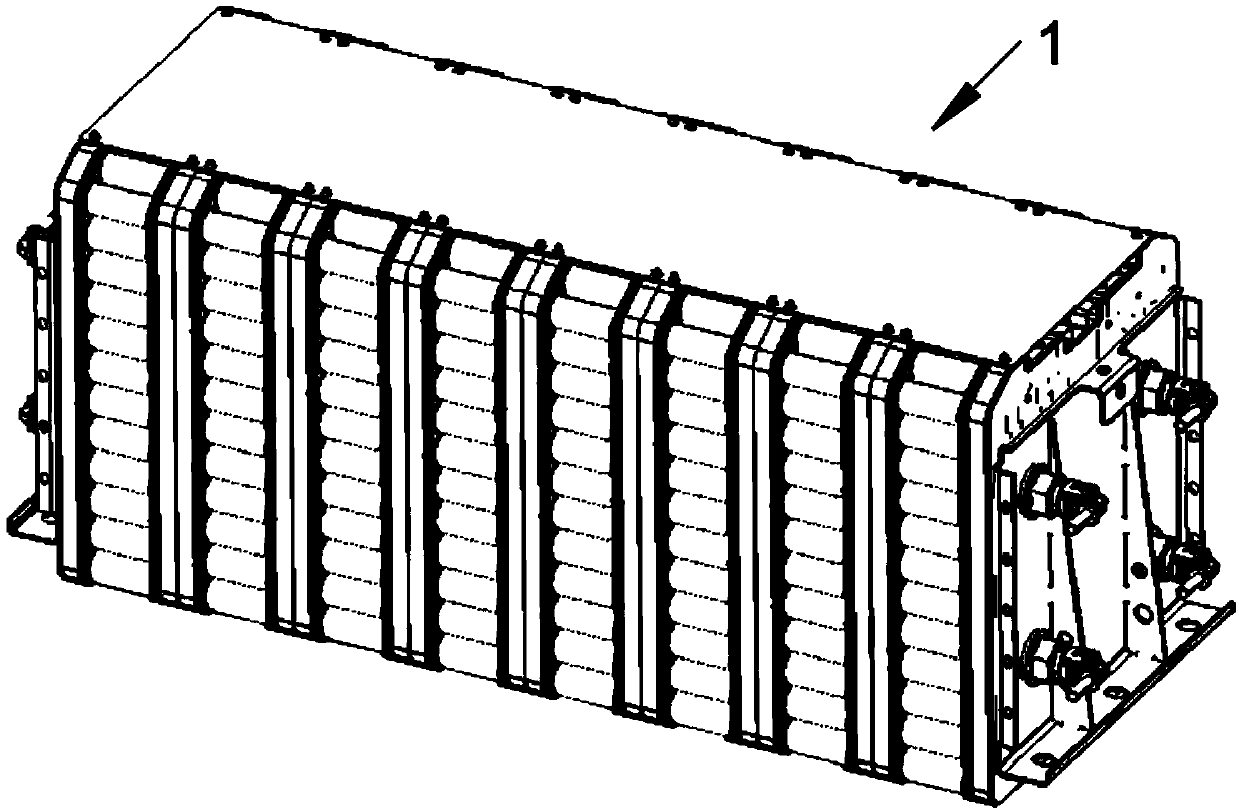

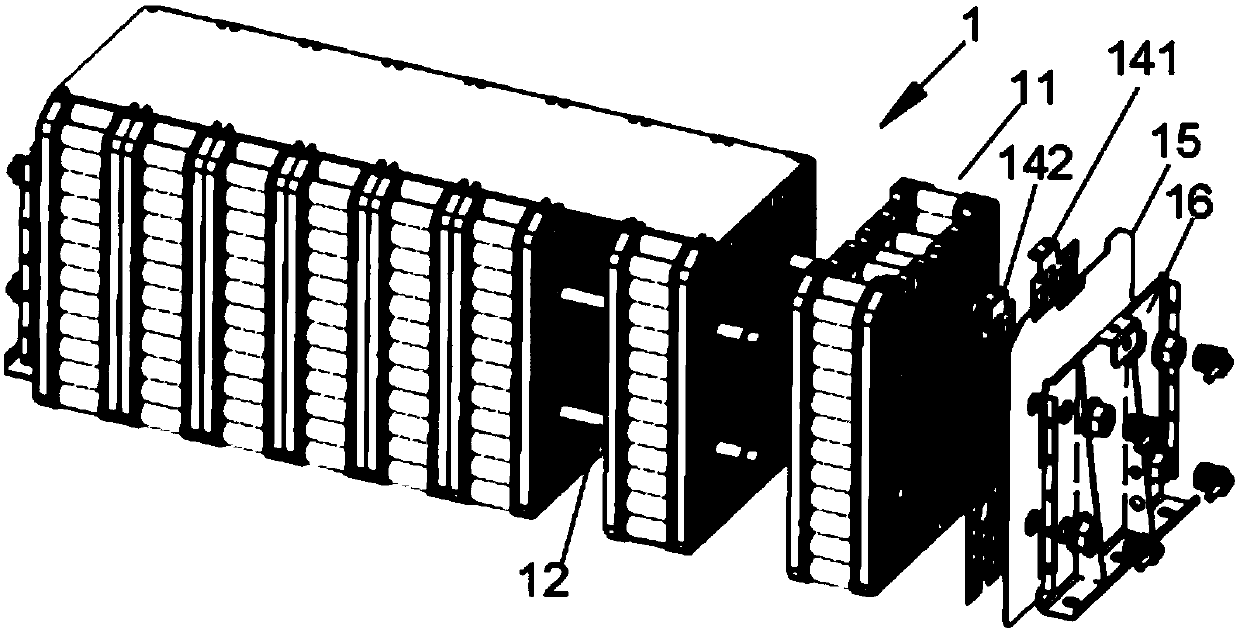

[0035] Embodiment: a kind of liquid-cooled cylindrical cell battery module, such as Figure 2-Figure 9 As shown, the battery module 1 includes several series-connected battery modules 11 and hollow fasteners 12. The fasteners pass through several series-connected battery modules and are locked tightly. cooling liquid;

[0036] The battery module includes a cell unit 110, and the cell unit includes several single cylindrical cells 1111, the several single cylindrical cells are arranged side by side with gaps between adjacent cylindrical cells, the Both ends of the cell unit are respectively provided with a heat conduction skeleton 114, and the heat conduction skeleton has a plurality of heat conduction through holes 1148, and the heat conduction through holes correspond to the single cylindrical cells one by one.

[0037] The battery module also includes two end insulating plates 15 and two module end plates 16, the two end insulating plates are respectively arranged on both s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com