Transfer and scheduling method based on two-dimensional code information

A technology of two-dimensional code information and dispatching method, which is applied in the field of logistics control and management of production line automation, can solve the problems of insufficient sharing of information, reduction of enterprise production efficiency, and ineffective use of process data and logistics information, etc., to achieve large The effect of maximizing equipment utilization, improving production efficiency, and optimizing logistics routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

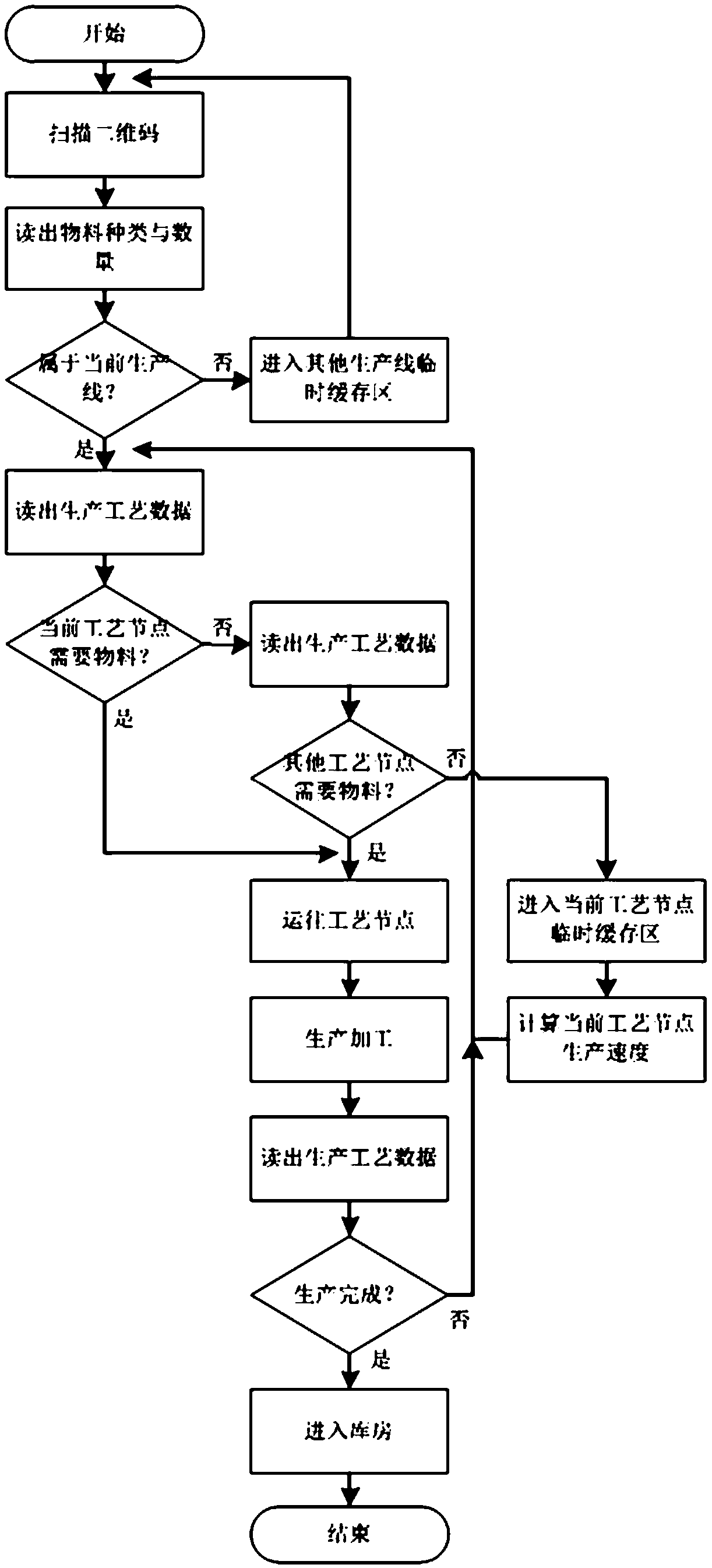

[0025] figure 1 It is a specific embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawings.

[0026] A transfer and scheduling method based on two-dimensional code information. Various materials required by the production line are placed on the transport device to and from each process node. There is a two-dimensional code indicating the material information on the transport device. The two-dimensional code scanning device is connected to each corresponding terminal of the production line system to scan the two-dimensional code of the transportation device. According to the different production lines or materials to be transported, the transport device can be a transport trolley or a conveyor belt. This specific implementation mode is embodied as a transport trolley, and the specific scheduling is as follows:

[0027] Step 1, start all the equipment in the production line and prepare to scan th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com