Ultra-thin injection molding production process integrated comprehensive workshop

A technology of injection molding and production process, applied in the direction of industrial buildings, etc., can solve the problems of high internal cost in the factory area, inconvenient logistics in the factory area, and not adapting to the needs of industrial production, so as to reduce the number and labor intensity of labor and improve production efficiency and economy. Benefits, the effect of meeting the needs of the food packaging industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

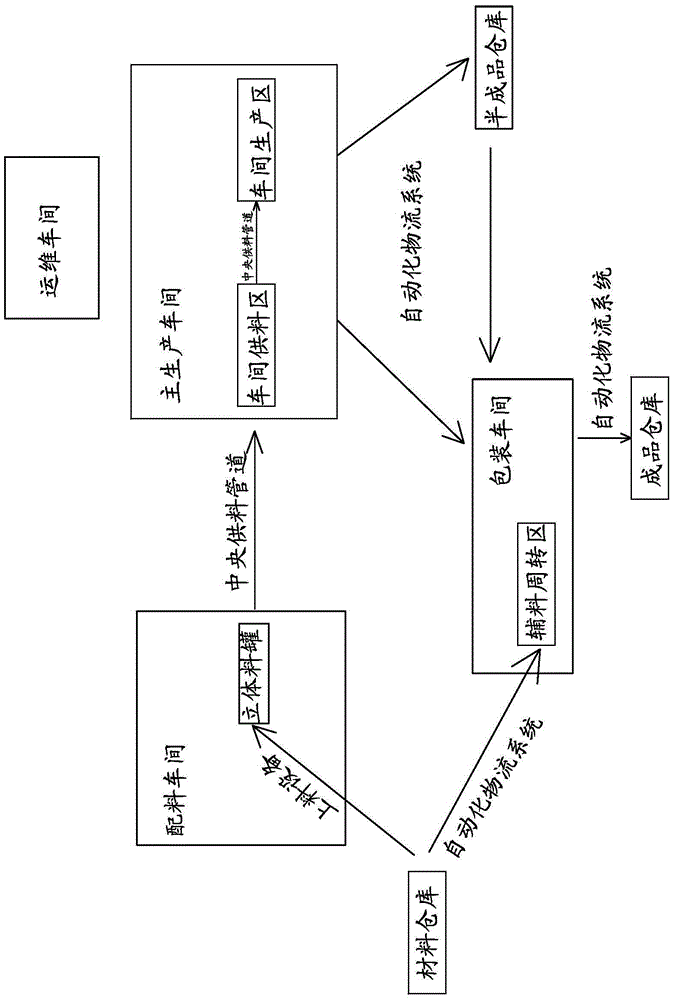

[0030] Ultra-thin injection molding production process integrated comprehensive workshop, such as figure 1 As shown, it includes material warehouse, batching workshop, main production workshop, semi-finished product warehouse, packaging workshop, finished product warehouse and the control center with central controller installed. The material warehouse is a three-dimensional automatic warehouse for storing raw materials and packaging accessories. The three-dimensional automatic warehouse Including regularly distributed multi-layer shelves, standard pallets where ingredients can be placed, automatic storage sorting equipment and automatic storage sorting equipment, automatic storage sorting equipment and automatic storage sorting equipment are respectively connected to the central controller . For the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com