A pressure relief structure of memory alloy insensitive ammunition

A memory alloy and pressure relief structure technology, applied in the field of bomb bottom pressure relief, can solve problems such as gunpowder gas entering the inside of the bomb body, reducing the structural strength of the bomb, and chamber explosion accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

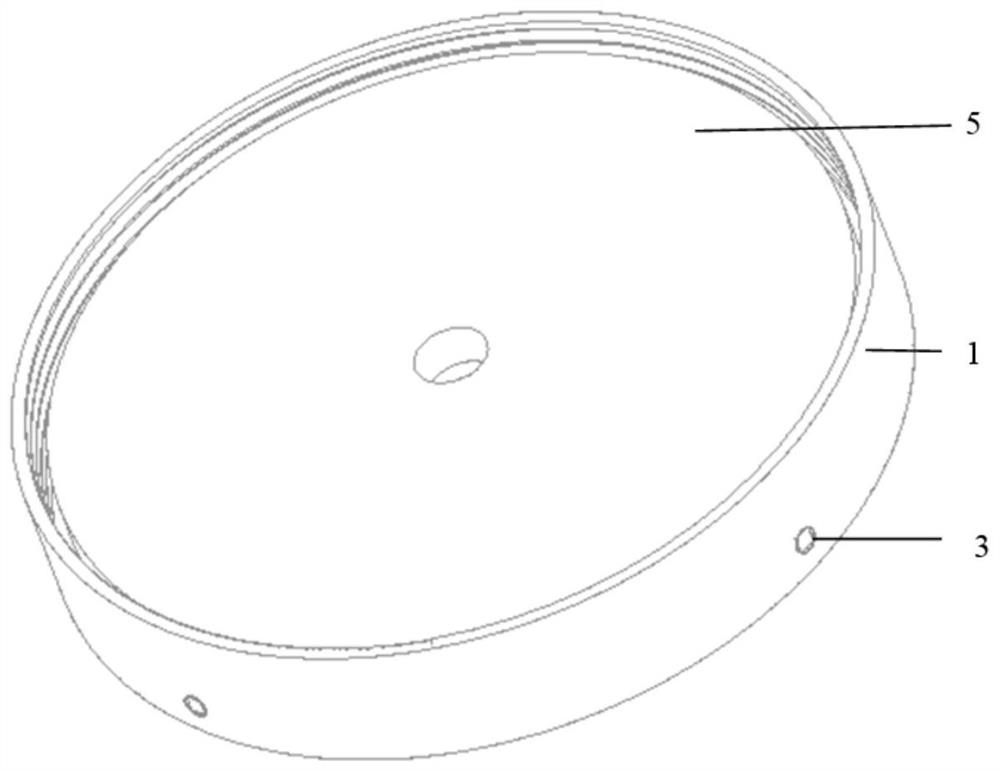

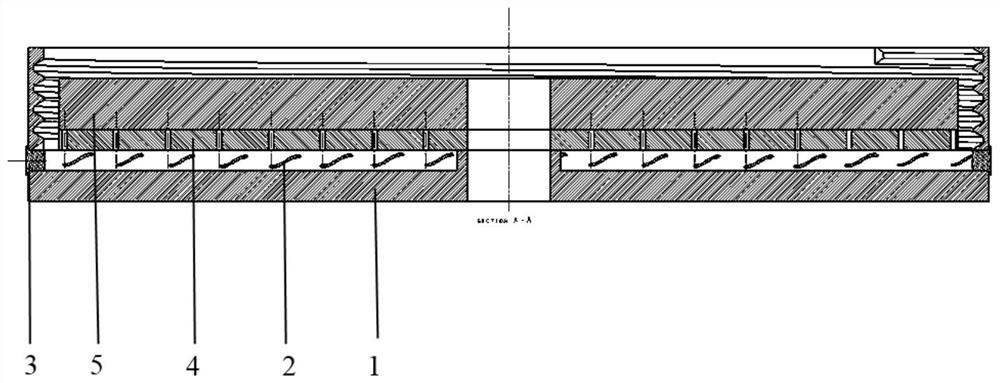

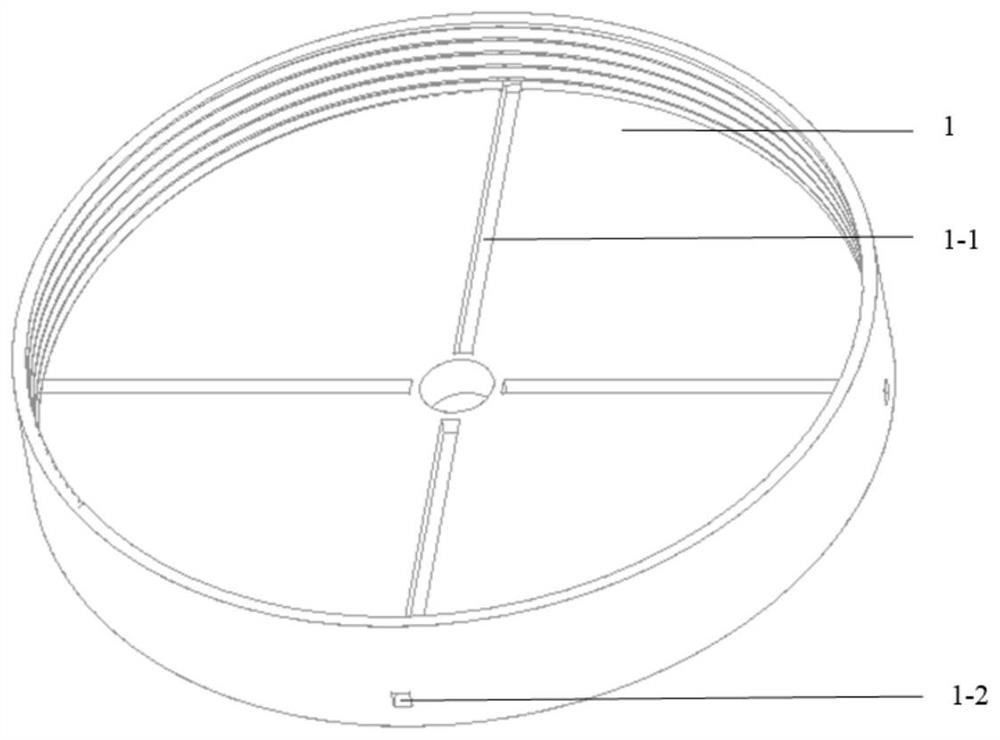

[0022] combine Figure 1-Figure 7 , a memory alloy type insensitive ammunition pressure relief structure of the present invention, comprising a bullet base 1, a memory alloy type spring 2, a sealing plug 3, an air guiding plate 4, and a breathable buffer sheet 5;

[0023] The air guide plate 4 and the breathable buffer sheet 5 are sequentially arranged in the bomb bottom 1 from the bottom up; explosives or other devices for detonating explosives. The bomb bottom 1 is evenly arranged with a plurality of grooves 1-1 in the radial direction, and the grooves 1-1 pass through the side wall of the bomb bottom 1 to form a pressure relief hole 1-2; the sealing plug 3 is arranged on the pressure relief On the hole 1-2, to block the pressure relief hole 1-2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com