Positioning method for kiln head burner in novel dry cement production line

A kiln head burner and dry-process cement technology, applied in the field of building materials, can solve the problems of unsmooth flame, incomplete combustion, rapid burning, etc., and achieve the increase of effective combustion space, reasonable heat distribution, and sufficient pulverized coal combustion space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

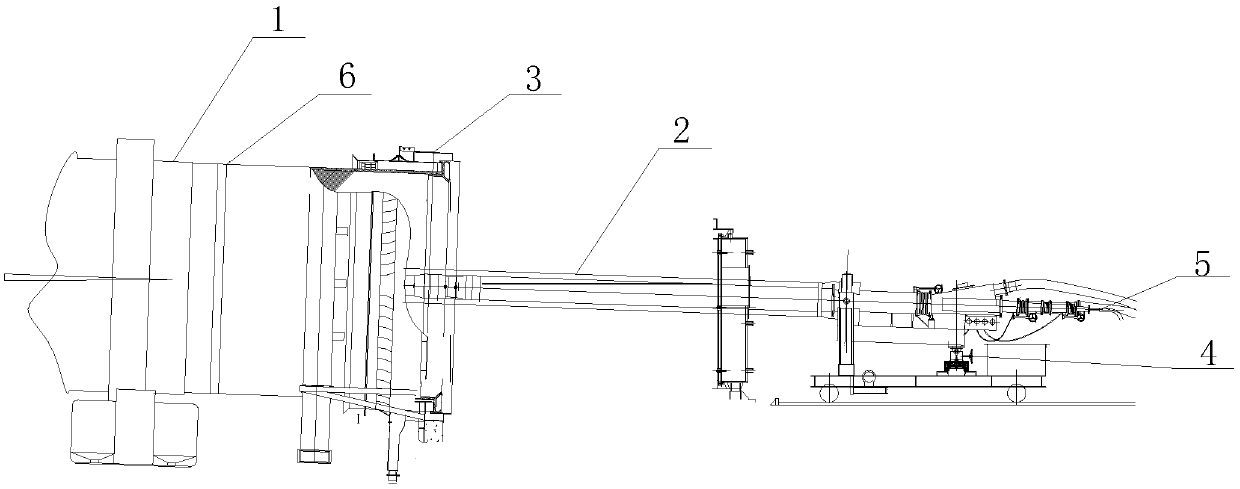

[0035] Such as figure 1 Among them, the coordinate position of the burner 2 center on the kiln hood is its basic position. Before determining the relative position of the burner 2 and the rotary kiln 1, the coordinate position of the end face of the burner 2 at the kiln mouth 3 should be determined first. First, measure the distance from the center of the support point of the burner 2 to the two ends of the rotary kiln 1 cylinder through the measuring device, and adjust the support point so that it is located on the central axis of the kiln cylinder. Then adjust the left and right position of the center point of the end face of the burner head relative to the center point of the kiln mouth, and adjust the left and right swinging handwheel of the burner so that the two center points are on the same vertical line. Then use a laser pointer to confirm with the center position of the oil pipe channel at the tail of the kiln head burner, adjust the elevation angle of the burner 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com