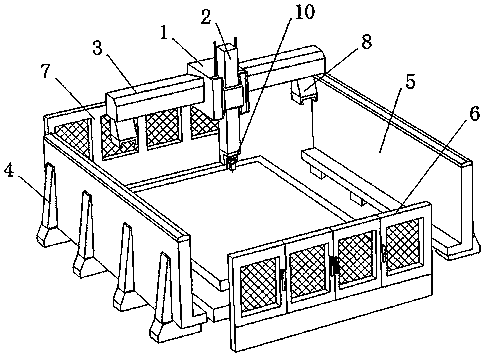

Assembled five-axis foam engraving machine

An engraving machine and assembled technology, applied in the direction of decorative art, processing models, etc., can solve the problems of tool blocking, increase the friction between the beam sliding block and the frame bed baffle, and the impact of engraving accuracy, so as to reduce the fracture. The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see Figure 1-2 , an assembled five-axis foam engraving machine, including a frame bed, the frame bed includes a workbench and a plurality of support bottom columns 4, the support bottom columns 4 are clamped with the workbench, and the plurality of support bottom columns 4 are respectively Located on both sides of the workbench, the front and rear ends of the workbench are respectively connected by bolts to the rack rear door assembly 7 and the rack front door assembly 6, and the rack front door assembly 6 and the rack rear door assembly 7 are equipped with nets. A layer of silica gel mesh is attached to the surface of the mesh window. The silica gel mesh can effectively absorb foam debris and reduce the phenomenon of foam debris flying outward. The left and right ends of the workbench are equipped with a machine bed. The baffle plate 5, the frame bed baffle plate 5, the frame front door assembly 6 and the frame rear door assembly 7 make a large amount of foam debris a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com