A mixing drum for rust remover production

A technology of mixing and stirring and rust remover, which is applied in the direction of mixer, mixing method, mixed material pretreatment, etc., can solve the problems of insufficient dissolution and mixing, poor mixing effect, etc., and achieve rapid and effective dissolution and mixing, and good dissolution and mixing effect , good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

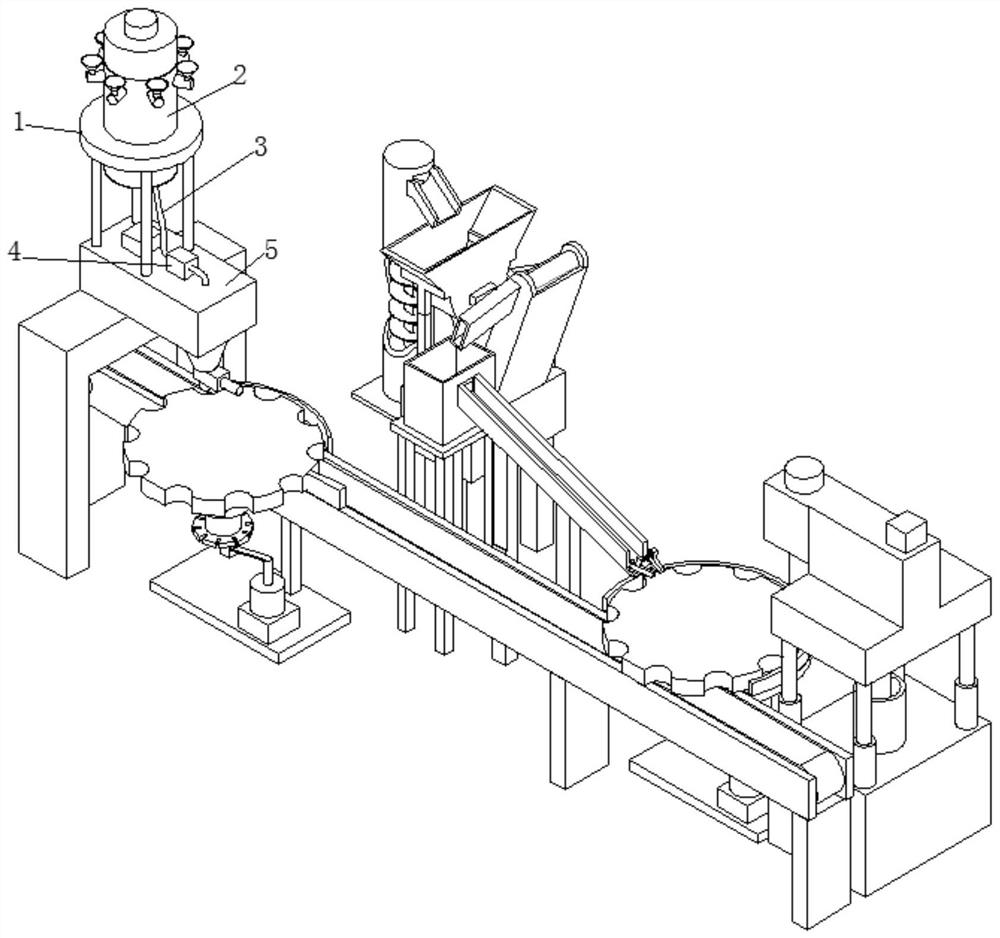

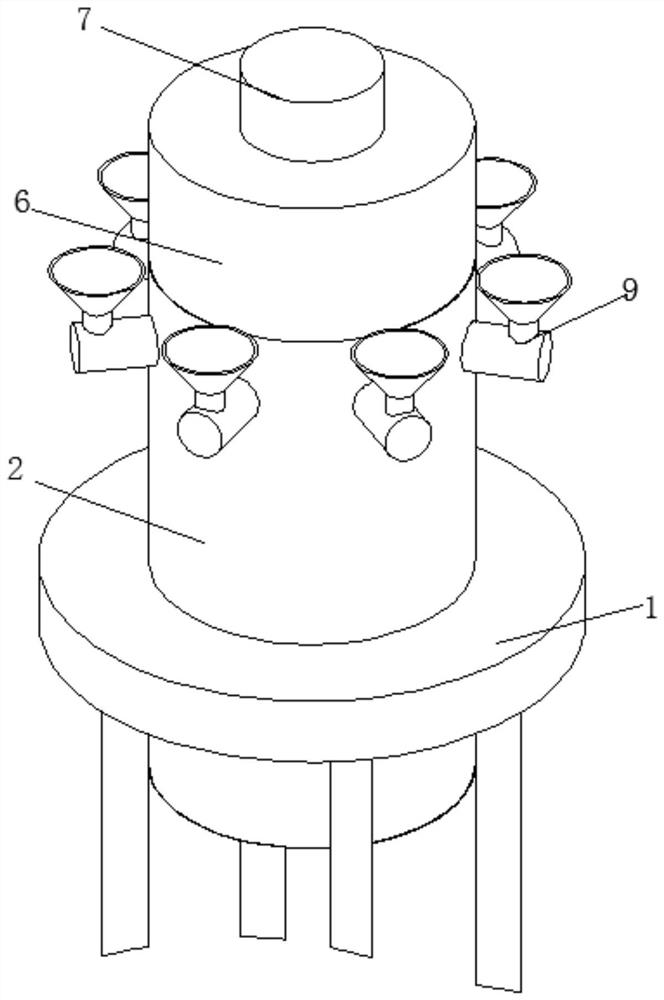

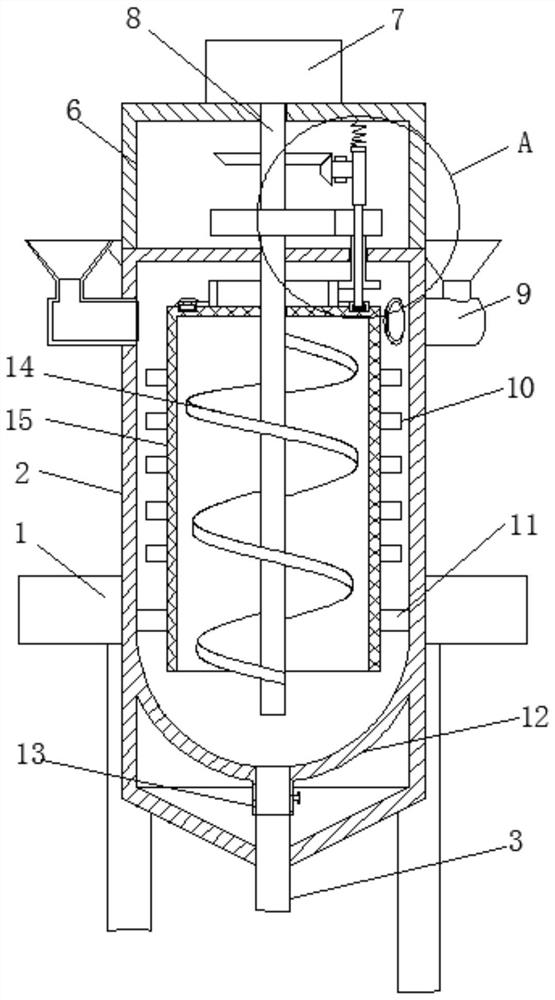

[0027] refer to Figure 1-5 , a mixing drum for rust remover production, comprising a support frame 1, a cylinder body 2 is fixedly connected to the support frame 1, an upper cover 6 is fixedly connected to the cylinder body 2, and a drive motor 7 is fixedly connected to the upper cover 6, The driving end of the drive motor 7 is connected with a drive shaft 8, the lower end of which is placed in the cylinder 2, the drive shaft 8 is connected with a spiral stirring plate 14, and the cylinder 2 is connected with a stirring mesh cylinder 15 through a swivel 11 for rotation, stirring The upper end of the mesh cylinder 15 is connected with the outer gear ring 17, the cylinder body 2 is rotatably connected with the first rotating shaft 24, the lower end of the first rotating shaft 24 is connected with the first gear 22 meshing with the outer gear ring 17, and the upper end of the first rotating shaft 24 is fixed. The second gear 25 is connected, and the drive shaft 8 is fixedly conn...

Embodiment 2

[0029] refer to Figure 1-5 , a mixing drum for rust remover production, comprising a support frame 1, a cylinder body 2 is fixedly connected to the support frame 1, an upper cover 6 is fixedly connected to the cylinder body 2, and a drive motor 7 is fixedly connected to the upper cover 6, The driving end of the drive motor 7 is connected with a drive shaft 8, the lower end of which is placed in the cylinder 2, the drive shaft 8 is connected with a spiral stirring plate 14, and the cylinder 2 is connected with a stirring mesh cylinder 15 through a swivel 11 for rotation, stirring The upper end of the mesh cylinder 15 is connected with the outer gear ring 17, the cylinder body 2 is rotatably connected with the first rotating shaft 24, the lower end of the first rotating shaft 24 is connected with the first gear 22 meshing with the outer gear ring 17, and the upper end of the first rotating shaft 24 is fixed. The second gear 25 is connected, and the drive shaft 8 is fixedly conn...

Embodiment 3

[0032] refer to Figure 1-5 , a mixing drum for rust remover production, basically the same as embodiment 2, the difference is that the gear teeth of the half-toothed driving bevel gear 30 and the gear teeth of the third gear 16 are misplaced; realize the mixing net cylinder 15 The up and down motion and the rotating motion of the stirring net tube 15 work alternately, and the effect of stirring and dissolving is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com