Novel offline reverse osmosis membrane cleaning equipment and cleaning process

A technology for reverse osmosis membrane and cleaning equipment, which is applied in the field of new offline reverse osmosis membrane cleaning equipment and its cleaning process, can solve the problems of reduced cleaning efficiency, pollution and cleaning effect, so as to ensure effective ingredients, shorten cleaning process, Improved cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Referring to the drawings in the description, the device structure and working principle of a novel off-line reverse osmosis membrane cleaning device and its cleaning process in the embodiments of the present application can be described completely and clearly.

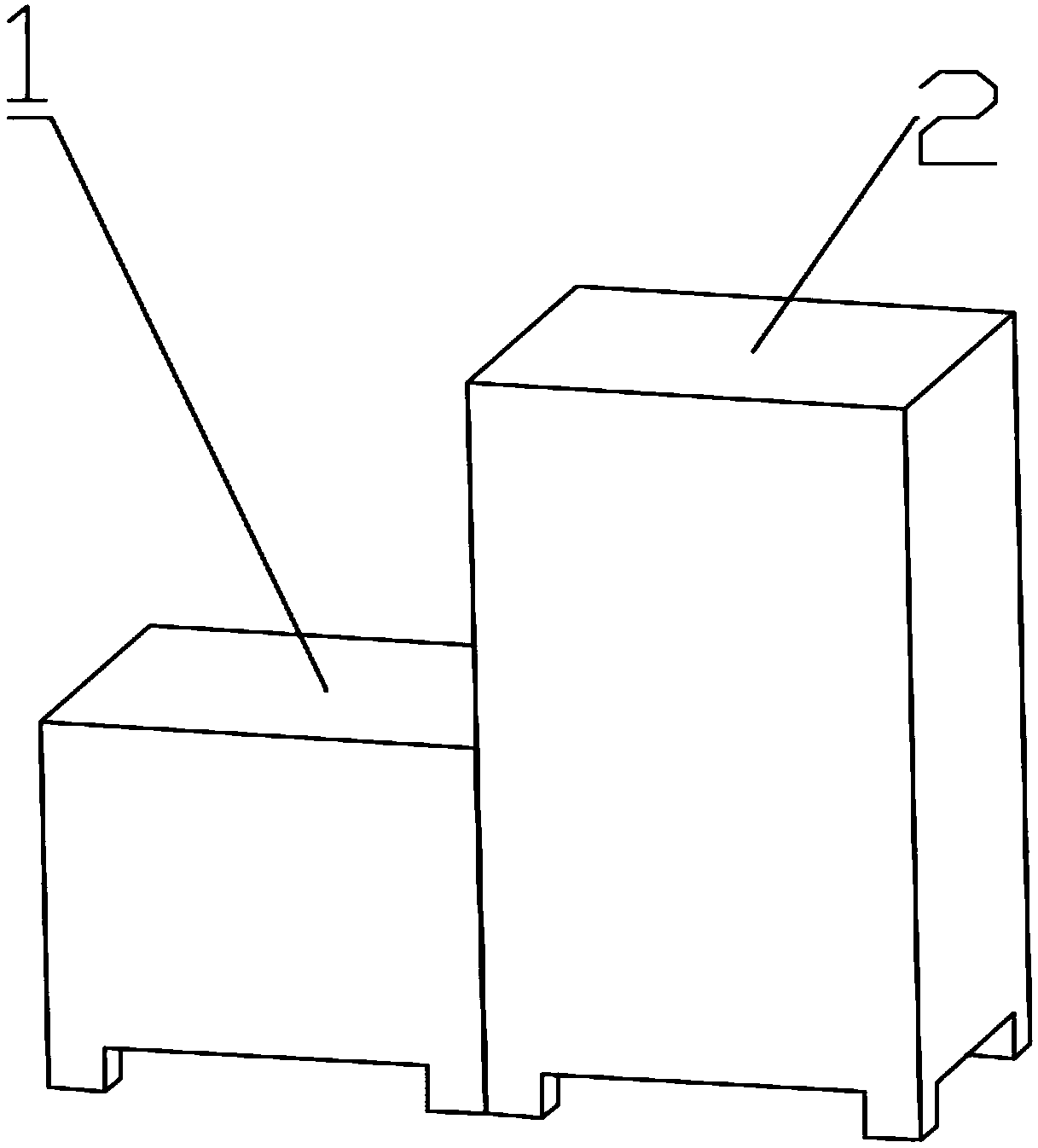

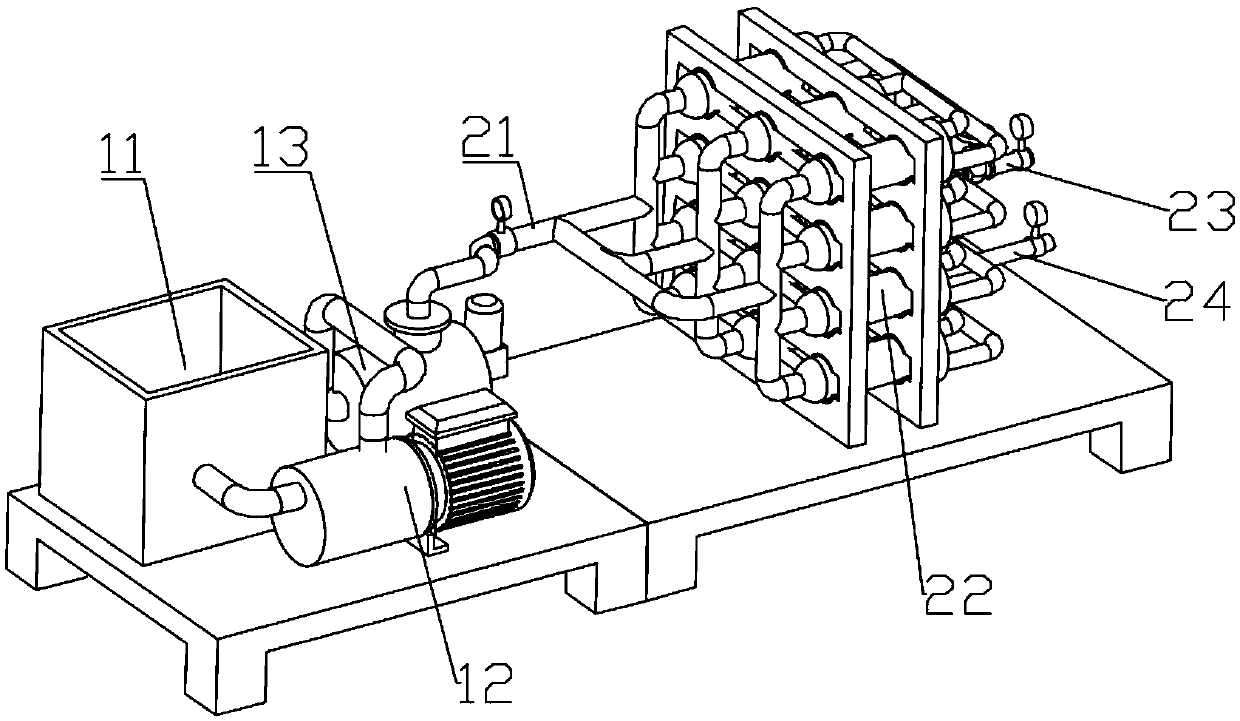

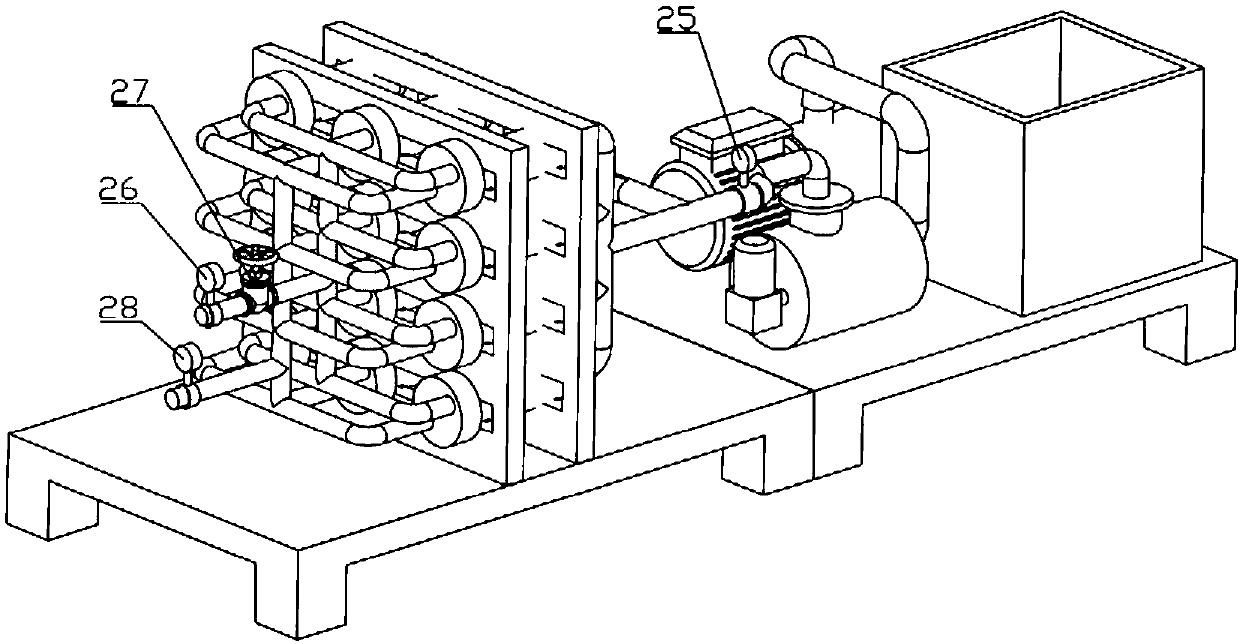

[0050] Among them, in the figure 1 middle:

[0051] The embodiment of the present application provides a new type of off-line reverse osmosis membrane cleaning equipment, which includes: a cleaning liquid supply part 1, the cleaning liquid supply part 1 is used for supplying cleaning liquid; a cleaning part 2, the cleaning part 2 is connected The cleaning liquid supply part 1 and the cleaning part 2 are used for cleaning the reverse osmosis membrane.

[0052] Based on the same inventive concept, the embodiment of the present application also provides a cleaning process, which includes: cleaning liquid supply, the cleaning liquid supply part 1 supplies reverse osmosis membrane cleaning liquid; reverse osmosis m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com