Fig-flavored enzyme rich in dietary fiber and preparation method thereof

A dietary fiber and fig technology, applied in the field of food processing, can solve the problems of reduced nutritional value, nutrient consumption, and low content of active substances, and achieve the effects of enhanced digestion and absorption, good sensory properties, and increased juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

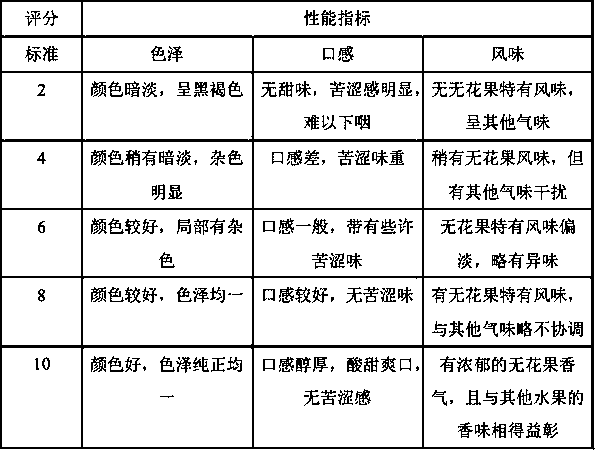

Image

Examples

Embodiment 1

[0034] Take by weighing each raw material according to the corresponding embodiment 1 data of table 1

[0035] A fig-flavored enzyme rich in dietary fiber

[0036] (1) Pre-treatment: Wash fresh figs, bamboo shoots, pitted pomegranates, and peeled coconuts, and soak them in color-protecting solution for 2 hours.

[0037](2) Raw material refining: Take the above raw materials out of the color protection solution and drain them quickly, and add pure water twice the weight of the raw materials, and use a combined colloid mill to refine the raw materials step by step at 50-55°C. As far as the combined colloid mill system is composed of 4 colloid mills in series, and the shear force gradually increases, the speed of the first colloid mill is 600rpm / min, the speed of the second colloid mill is 800rpm / min, and the third colloid mill The rotational speed of the mill is 1000 rpm / min, the rotational speed of the fourth colloid mill is 1500 rpm / min, the shearing time of each colloid mill...

Embodiment 2

[0045] Take each raw and auxiliary material by the corresponding embodiment 2 data of table 1

[0046] A fig-flavored enzyme rich in dietary fiber

[0047] (1) Pre-treatment: Wash fresh figs, bamboo shoots, pitted pomegranates, and peeled coconuts, and soak them in color-protecting solution for 2 hours.

[0048] (2) Raw material refining: Take the above raw materials out of the color protection solution and drain them quickly, and add pure water twice the weight of the raw materials, and use a combined colloid mill to refine the raw materials step by step at 55°C, specifically The combined colloid mill system consists of 4 colloid mills connected in series, and the shear force gradually increases. The speed of the first colloid mill is 800rpm / min, the speed of the second colloid mill is 1000rpm / min, and the The rotating speed is 1500 rpm / min, the rotating speed of the fourth colloid mill is 2000 rpm / min, the shearing time of each colloid mill is 5 minutes, and then 7% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com