A motor cylinder with water cooling and air cooling functions

A motor cylinder and cylinder block technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of increased motor temperature, limited efficiency of air cooling, and inability to adapt to heat dissipation requirements, so as to increase the distance and improve the Heat transfer efficiency and the effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

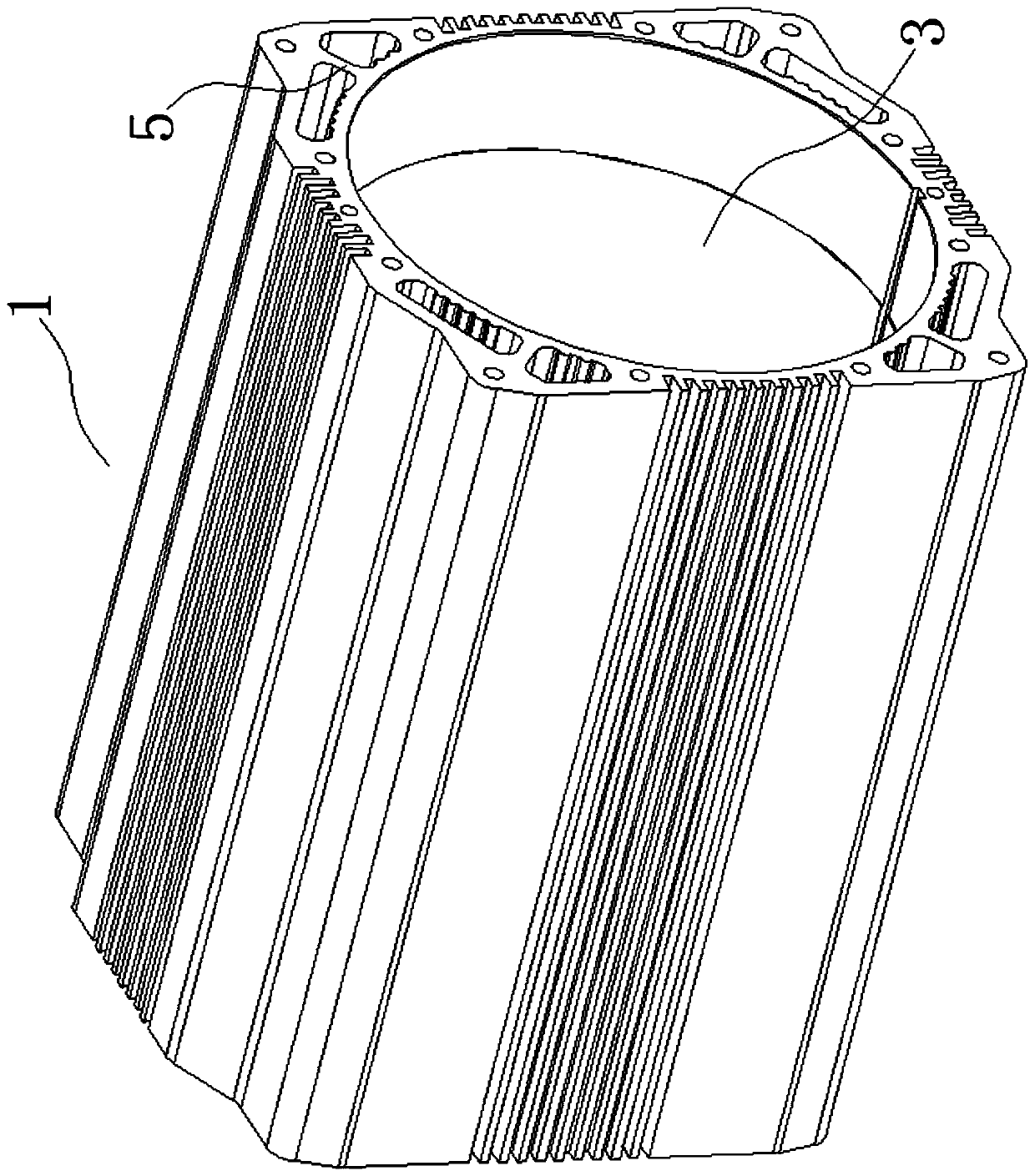

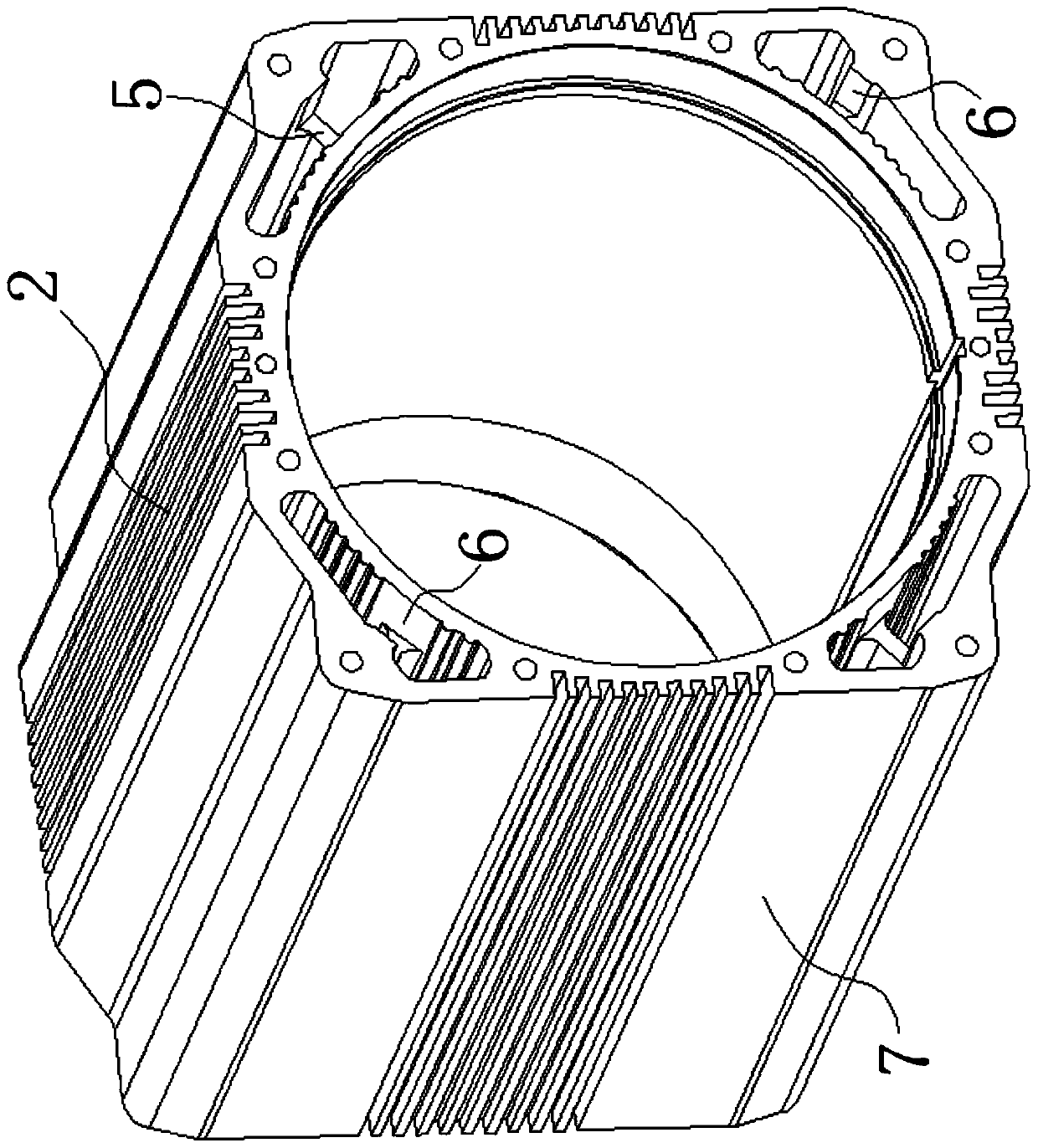

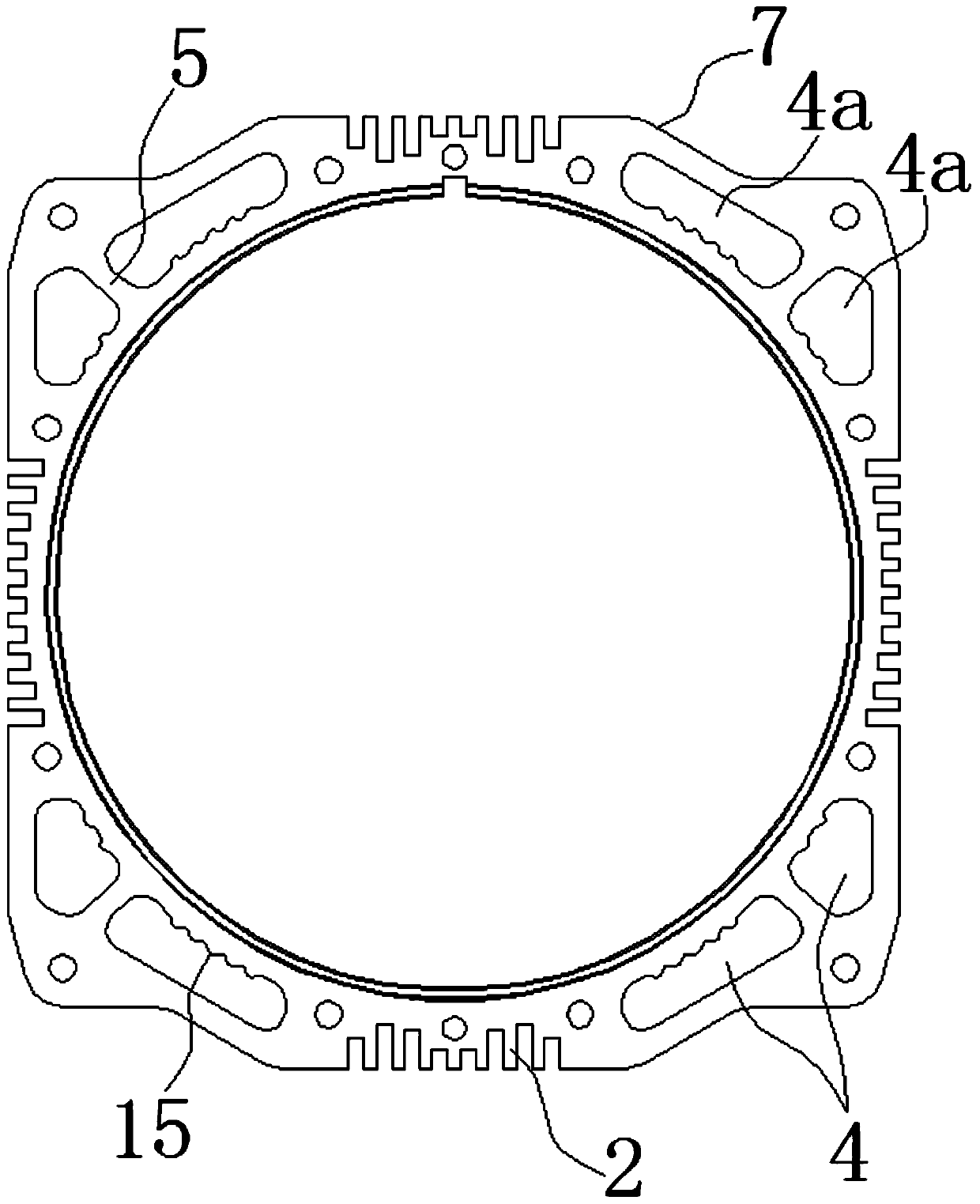

[0035] In order to achieve the purpose of the present invention, a motor cylinder with water-cooling and air-cooling functions includes: a cylinder 1 with an inner cavity 3 for accommodating the rotor, the outer wall of the cylinder 1 is provided with cooling fins 2, and the inner cavity of the cylinder 1 3 and the outer wall are provided with several lumens 4 for the cooling water to flow through. The length direction of the lumens 4 is parallel to the axis of the cylinder body 1 itself. A partition rib 5 is arranged in the lumens 4 along the axial direction of the cylinder body 1. The separation rib 5 divides each lumen 4 into two single pipes 4a, the same end of the separation rib 5 is provided with an axially recessed gap 6, and the gap 6 communicates with the two single pipes 4a in the same lumen 4; the end cap, Assembled with the end of cylinder block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com