Intelligent refueller for assisting in gas filling

A technology for assisting inflators and refueling machines, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of high risk, damage to oil pillows, and long preparation time, and achieve the effects of easy operation and promotion, oil saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

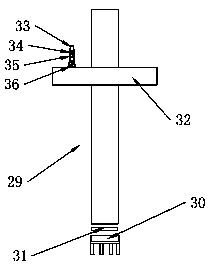

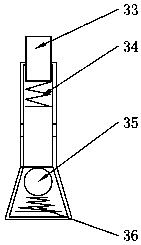

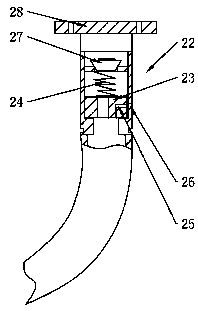

[0037] refer to Figure 1-6 As shown, the intelligent fuel dispenser for auxiliary inflation includes a body 1. A control panel 2, an oil pump 3, an air compressor 4 and an AC motor 6 electrically connected to the control panel 2 through a frequency converter 5 are installed in the body 1. There is an air storage tank 7 communicating with the end of the air outlet pipe of the air compressor 4, and the outlet end of the air storage tank 7 is connected with the breathing pipe of the transformer; The electromagnet A connected to the power of the AC motor 6, the air outlet end of the air compressor 4 is provided with an air charging interface connected to the breathing tube 18 of the oil barrel and the transformer respectively, and the oil pump 3 is equipped with a valve connected to the control panel 2 and controls the connection between the oil pump 3 and the AC. The electromagnet B connected to the power of the motor 6, the oil pressure sensor 21 connected to the control panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com