Compact vibration drying/cooling fluidized bed and parameter determination method thereof

A cooling fluidized bed, vibration drying technology, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc. emission reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

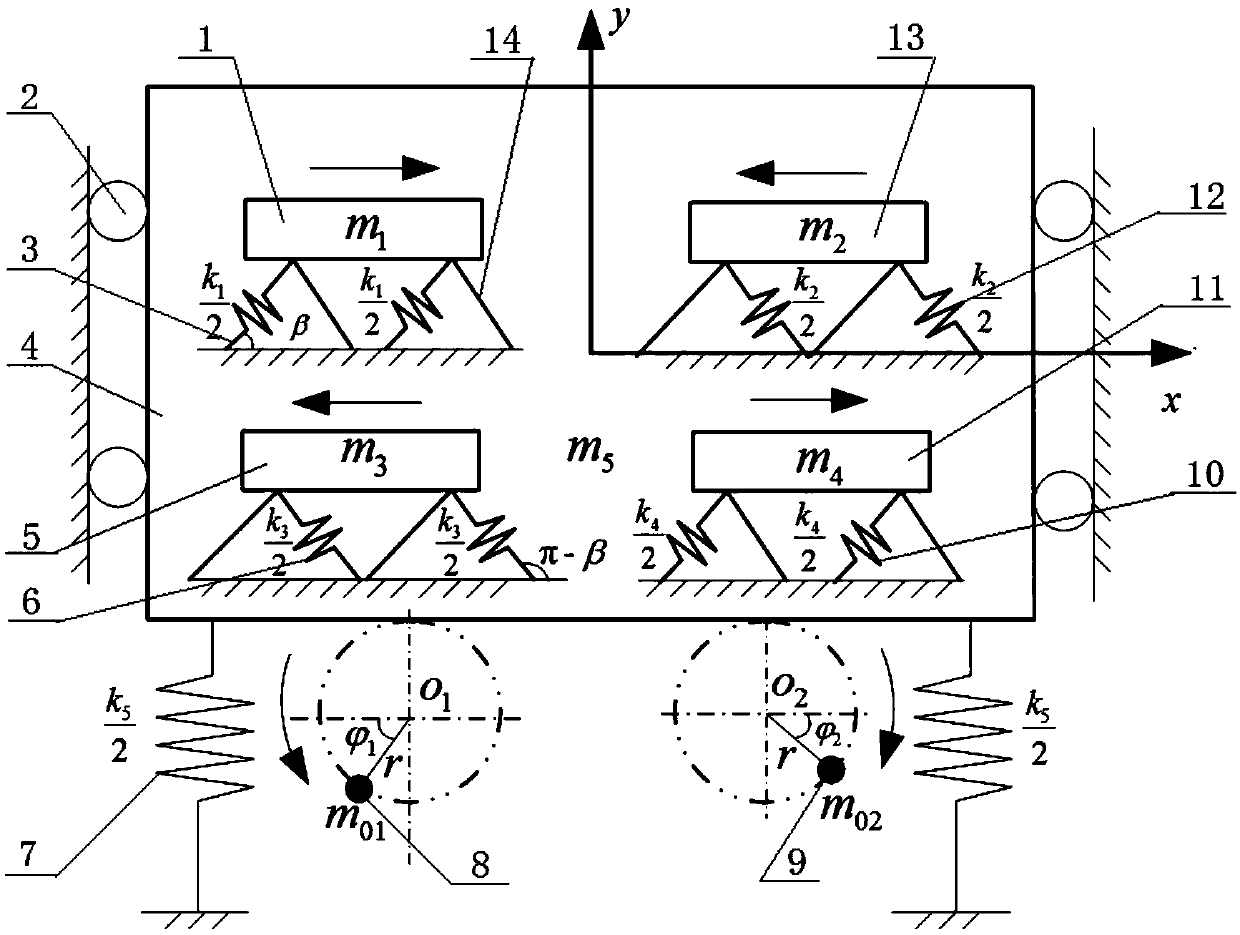

[0141] A compact vibrating drying / cooling fluid bed. Its dynamic model see figure 1 , including: 1. Plastid 1; 2. Rubber pad; 3. Spring 1; 4. Plastid 5; 5. Plastid 3; 6. Spring 3; 7. Spring 5; 8. Vibrator 1; 9. Vibrator 2; 10. Spring 4; 11. Mass body 4; 12. Spring 2; 13. Mass body 2; 14. Guide plate.

[0142] The model consists of five plastids, two vibrators and five sets of springs. Rubber pads are installed between plastid 5 and the base. Plastids 1, 2, 3, and 4 are connected to plastid 5 by springs. , at the same time, the plastid 5 is connected to the foundation through the spring 5 . Such as figure 1 , the radius of gyration of the vibrator on mass body 5 is r. Vibrator 1 and vibrator 2 rotate in opposite directions.

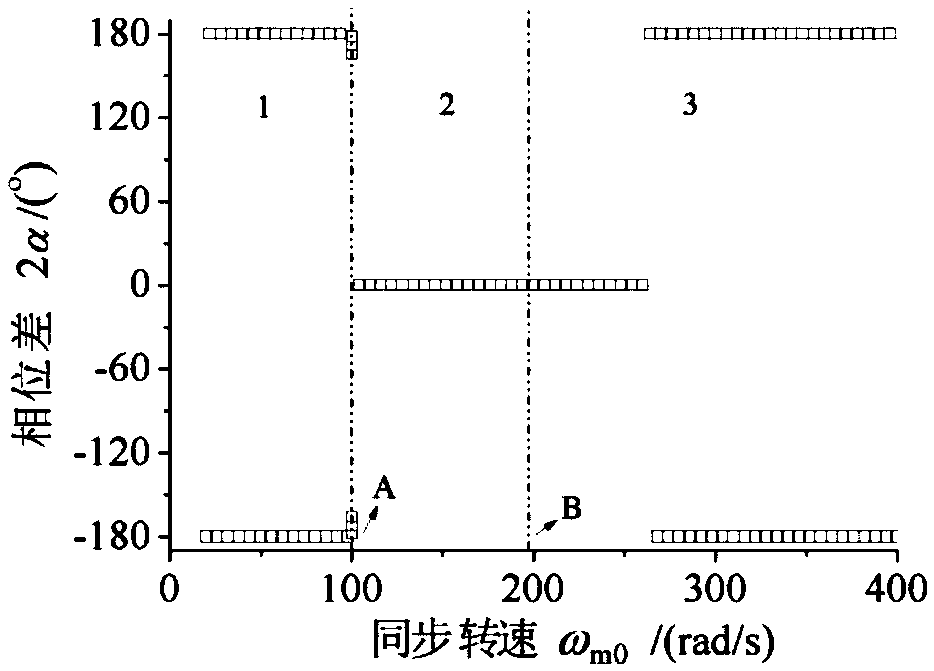

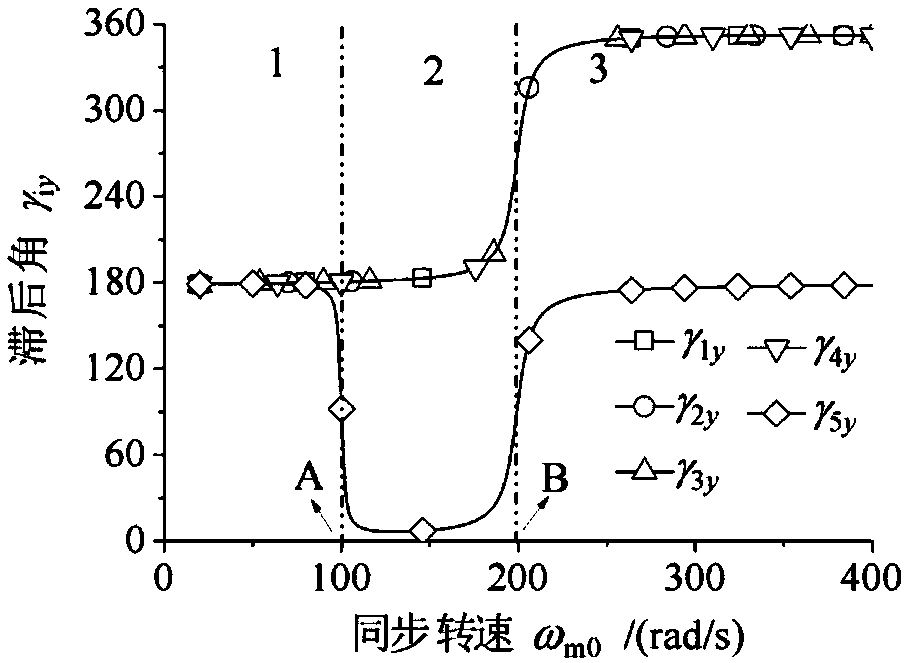

[0143] Numerical analysis of two-mass four-machine driven vibration system

[0144] In order to clearly describe the motion characteristics of the vibrating system and verify the theoretical results, some numerical characteristic analyzes are given. ...

Embodiment 2

[0157] Embodiment 2: Simulation analysis of dual-mass four-machine drive vibration system

[0158] In order to further analyze and verify the numerical results, three sets of simulation results are given by the Runge-Kutta method. Vibration system parameters and motor parameters are given above. In order to obtain the motion state of the system in different regions, generally by changing the spring stiffness k iy (i=1,2,3,4,5) to adjust ω 2 and ω 0 value. At the same time, each group will give two simulation results for comparison.

[0159] (a) Simulation results of area I

[0160] take k 1y =k 2y =k 3y =k 4y =60000kN / m,k 5y =10kN / m,z 1 = 0.52. The system is in the first region, that is, with respect to ω 0 sub-resonance state.

[0161] Figure 6 Indicates that the motor in a stable state reaches a stable state in a relatively short period of time, and the synchronous speed is stable at around 983r / min. At 60s, when the motor 2 is disturbed, the motor speed has ...

Embodiment 3

[0176] Example 3: Example data parameters for a compact vibratory drying / cooling fluidized bed. The invention is not limited to this design parameter.

[0177] The springs connected to mass bodies 1, 2, 3, and 4 all have stiffness k 1y =k 2y =k 3y =k 4y =8000kN / m, connected to the mass body 5 spring stiffness k 5y =10kN / m,z 2 = 0.71. The masses of the plastids are m 5 =2000kg, m 1 =m 2 =m 3 =m 4 =1500kg, the mass of the eccentric rotor of the exciter m 01 =m 02 =10kg, M 5 =m 5 +m 01 +m 02 =2020kg, therefore, we can get the natural frequency of the system as ω 0 = 100rad / s, ω 4 = 199 rad / s. The models of the two motors are the same (three-phase squirrel-cage, 50Hz, 380V, 6 poles, 0.75kW, rated speed 980r / min), given the motor parameters: rotor resistance R r =3.40Ω, stator resistance R s =3.35Ω, mutual inductance L m =164mH, rotor inductance L r =170mH, stator inductance L s =170mH, damping f 1 = f 2 = f 3 = 0.05. At this time, the system is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com