Open double-reading head circular grating system quick installation and adjustment mechanism

A technology of installation and adjustment, dual reading heads, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as inability to install and adjust space instruments and equipment, inability to observe the state of reading heads and circular gratings, and complex adjustment methods. To achieve the effect of easy promotion and implementation, simple structure and improved mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

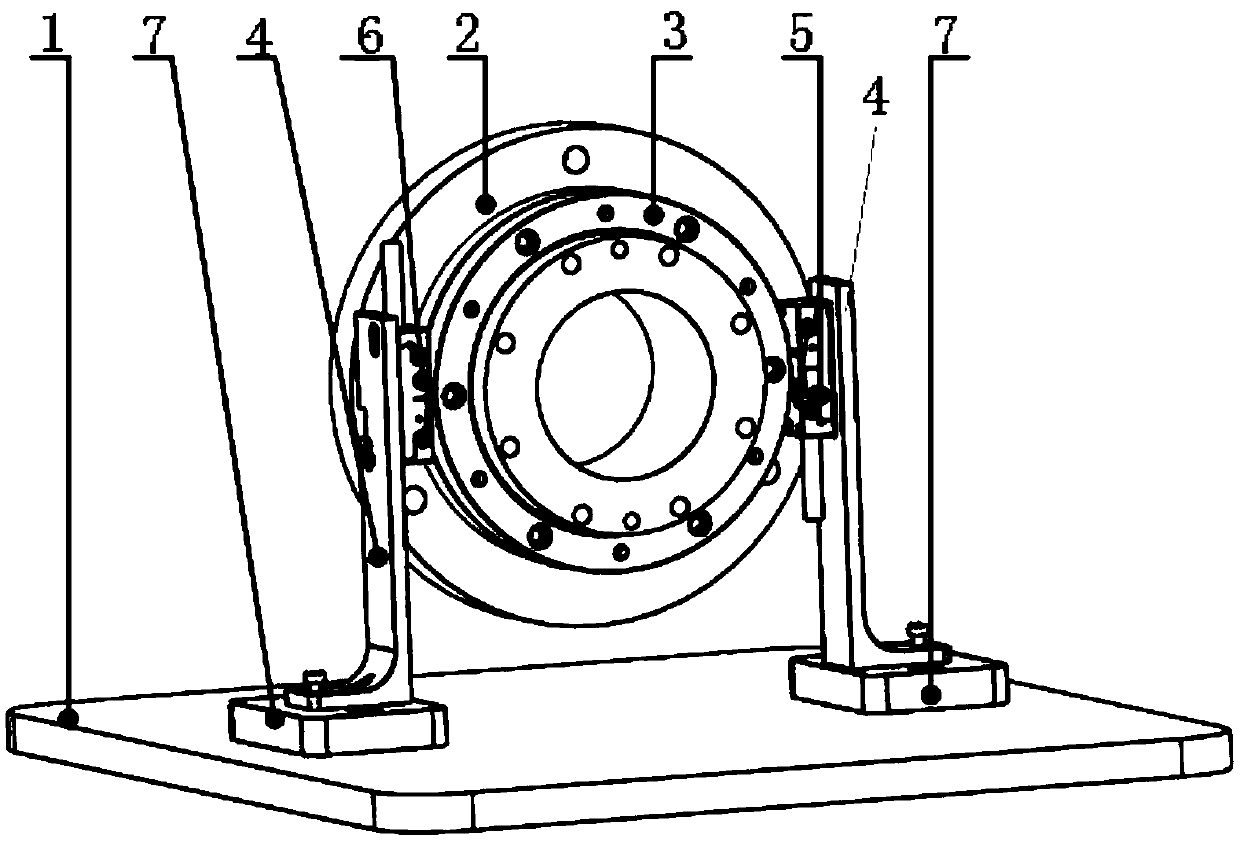

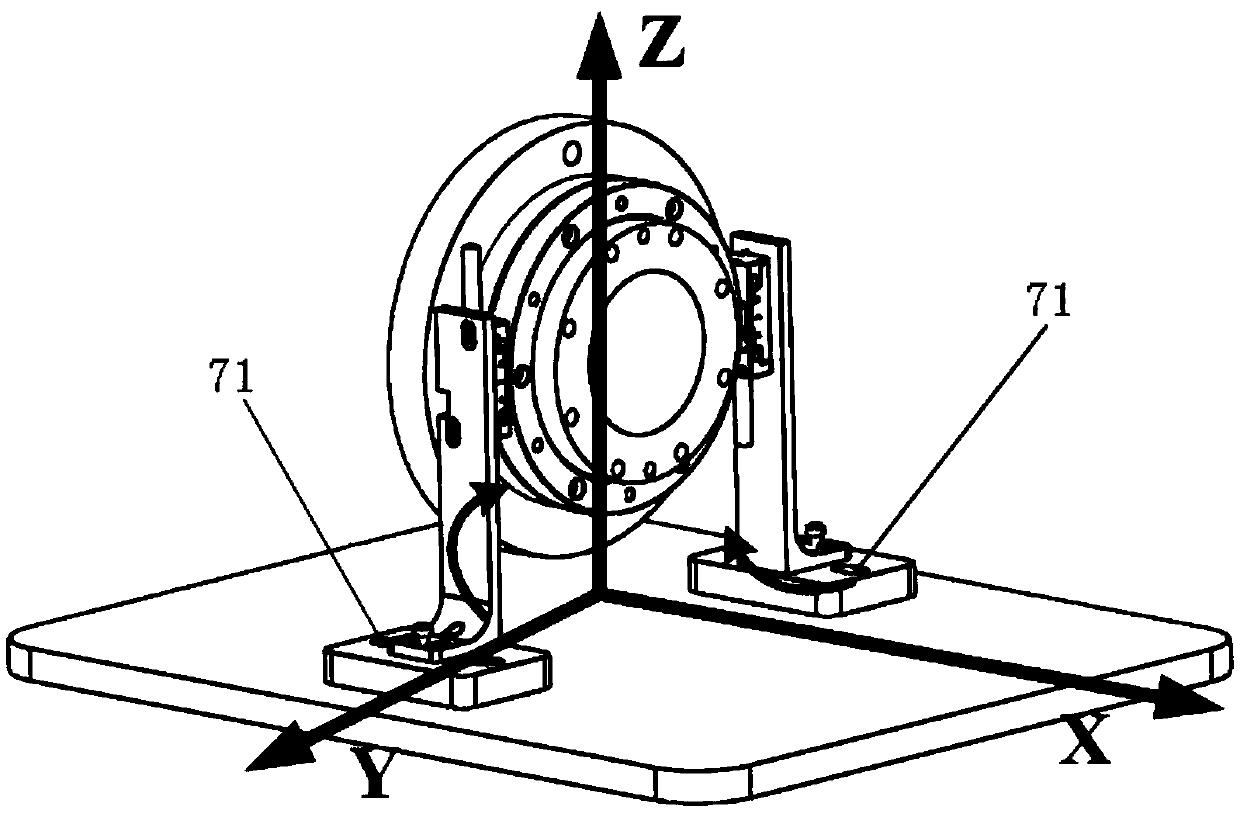

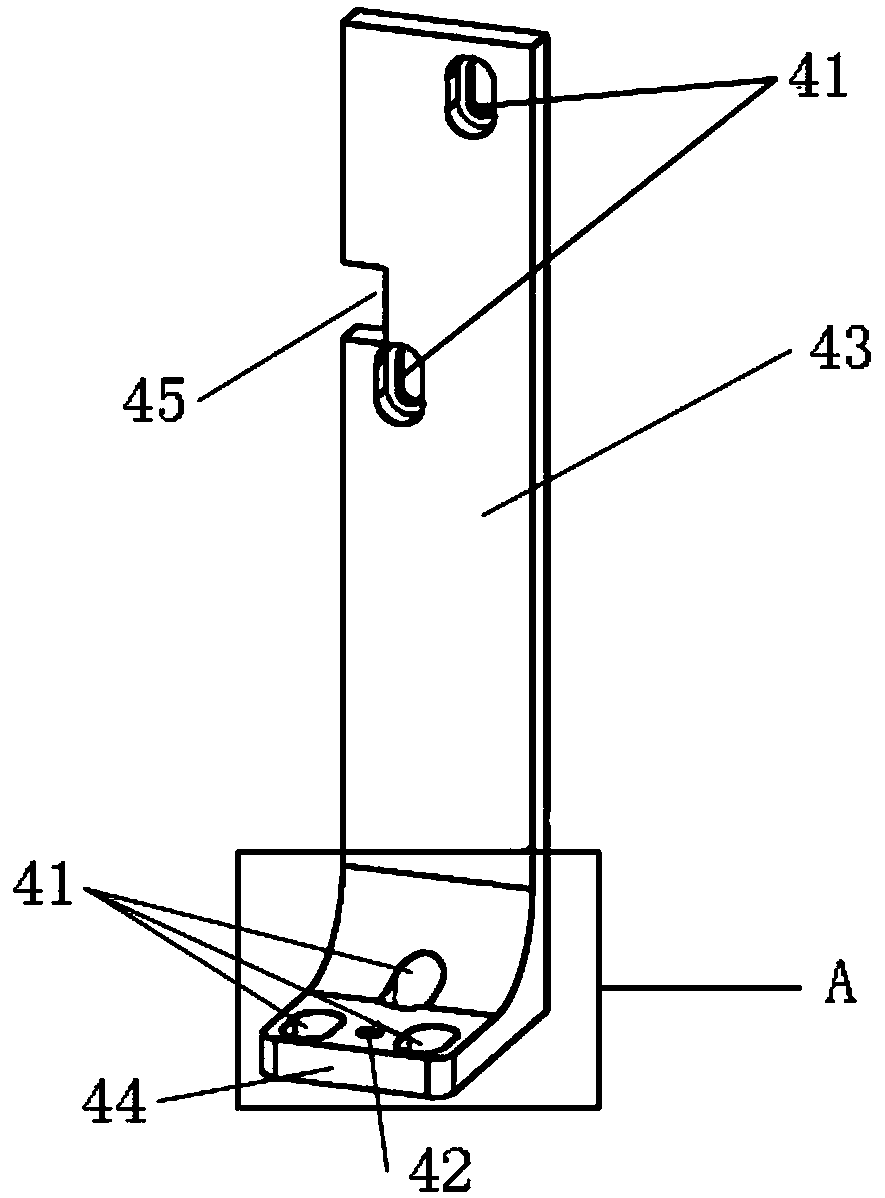

[0028] see Figure 1-Figure 3 , an embodiment of a quick installation and adjustment mechanism for an open double-reading head circular grating system, including a base plate 1, a flange plate 2 arranged above the base plate 1 and fixedly connected to a rotating motor, and a circle set on the conical surface of the flange plate 2 The grating 3 is provided with a reading head mounting seat 4 on both sides of the circular grating 3. The reading head mounting seat 4 is fixedly connected with the forward and reverse reading heads 5 and 6 with screws respectively. The bottom of the seat 4 is provided with a spacer 7, which is fixedly connected with the bottom plate 1 through countersunk screws; the reading head mounting seat 4 is provided with a plurality of first stepped slots 41 along the Z and Y directions for adjusting The distance between posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com