Magnetic drive reciprocation refrigeration compressor

A refrigeration compressor and magnetic drive technology, applied in the field of compressors, can solve the problems of compressor stability, vibration, and failure, etc., to improve stability and work efficiency, reduce possibility, and control noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

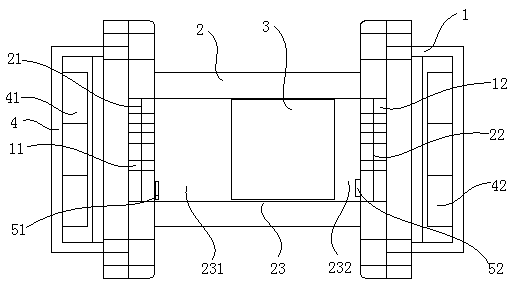

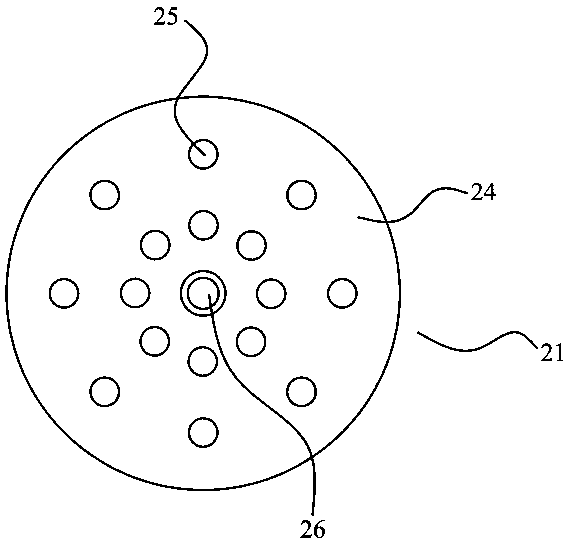

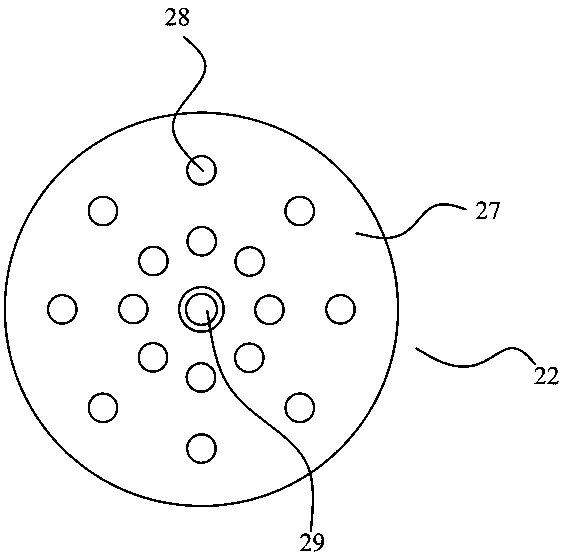

[0028] Such as Figure 1 to Figure 4 Shown is an embodiment of the magnetic drive reciprocating refrigeration compressor of the present invention, including a casing 1 and a cylinder 2 fixedly connected to the casing 1, one end of the casing 1 is provided with a first channel 11, and the other end is provided with a second channel. Channel 12, one end of the cylinder 2 is provided with a first valve 21 that controls the on-off of the first channel 11, and the other end is provided with a second valve 22 that controls the on-off of the second channel 12; the cylinder 2 is provided with a permanent magnet mover 3, Both ends of the casing 1 are provided with a magnetic drive mechanism 4 for driving the permanent magnet mover 3 to reciprocate in the cylinder 2 .

[0029] Such as figure 1 As shown, the cylinder 2 is provided with a compression chamber 23, and the permanent magnet mover 3 is movable in the compression chamber 23; the permanent magnet mover 3 has a cylindrical struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com